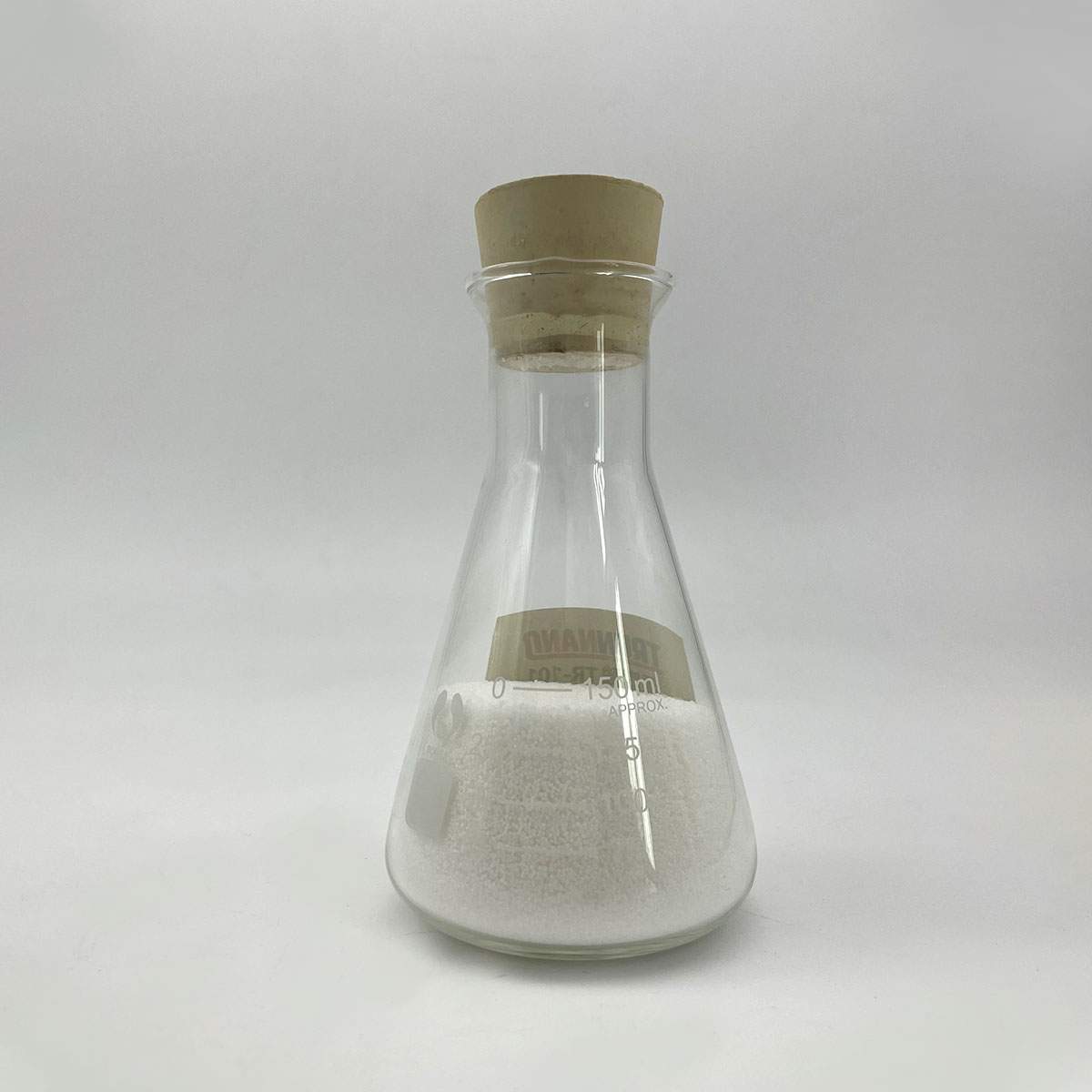

Overview of VNOVO Powder Nickel-coated molybdenum disulfide grease Resistance high quality lithium-based grease

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of VNOVO Powder Nickel-coated molybdenum disulfide grease Resistance high quality lithium-based grease

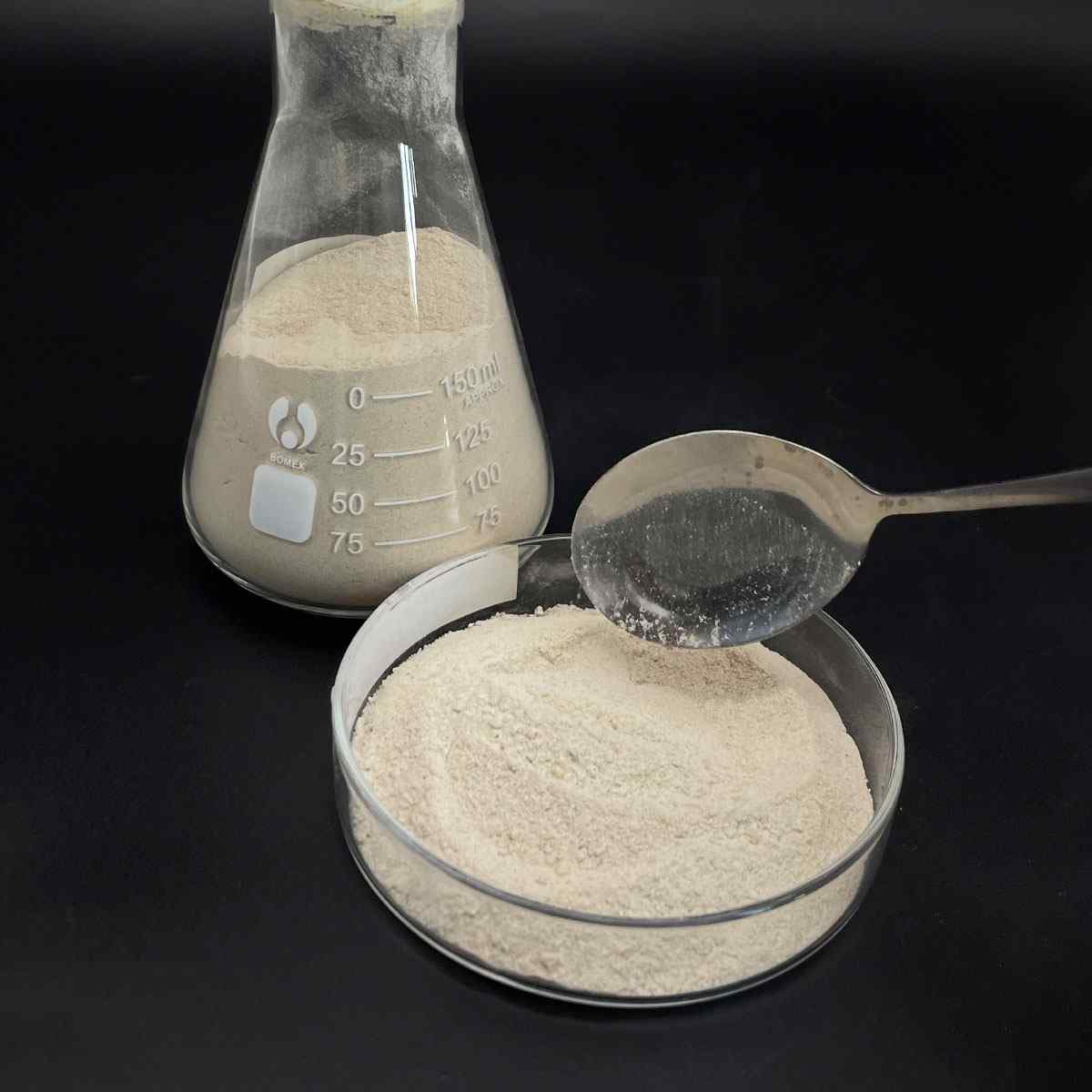

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(VNOVO Powder Nickel-coated molybdenum disulfide grease Resistance high quality lithium-based grease)

Parameters of VNOVO Powder Nickel-coated molybdenum disulfide grease Resistance high quality lithium-based grease

VNOVO Powder Nickel-Coated Molybdenum Disulfide Grease: A High-Performance, Lithium-Based Lubricant

In the realm of industrial lubricants, VNOVO’s innovative powder nickel-coated molybdenum disulfide (MoS2) grease stands out as a premium solution. This exceptional grease is designed with cutting-edge technology that combines the benefits of both molybdenum disulfide and a robust lithium-based formula. The result is a product that boasts unparalleled resistance to extreme conditions, making it an indispensable choice for various applications.

Molybdenum disulfide, renowned for its inherent self-lubricating properties, enhances the grease’s ability to reduce friction and wear. It forms a protective layer on metal surfaces, ensuring minimal sliding resistance even under heavy loads or high-speed operations. The nickel coating further enhances this performance by providing additional wear protection and corrosion resistance, extending the lifespan of machinery.

Lithium-based greases, on the other hand, offer superior thermal stability and excellent oxidative stability. They maintain their lubricating properties over a wide temperature range, from sub-zero freezing points to high operating temperatures. The VNOVO formula incorporates these advantages, ensuring consistent lubrication even in challenging environments where temperature fluctuations are prevalent.

The VNOVO Powder Nickel-Coated MoS2 grease is characterized by its high load-carrying capacity, which allows it to effectively support heavy machinery without compromising efficiency. Its thick, yet non-stick consistency ensures that it remains in place, providing long-lasting lubrication without clogging or attracting dust and debris.

Moreover, this grease is highly resistant to water, oil, and aggressive chemicals, making it ideal for use in environments prone to contamination or exposure to harsh chemicals. Its compatibility with a wide range of materials also ensures smooth operation across diverse components, reducing the risk of galling or seizing.

In terms of application, VNOVO’s grease is suitable for various industries, including automotive, aerospace, manufacturing, and heavy equipment. From bearings and gears to slides and valves, this grease proves to be a versatile solution that can withstand the rigors of daily use and demanding machinery.

In conclusion, VNOVO Powder Nickel-Coated Molybdenum Disulfide Grease is a game-changer in the world of lubrication. Its unique blend of molybdenum disulfide and lithium-based formulation, coupled with the added durability provided by the nickel coating, offers unparalleled performance in terms of resistance, thermal stability, and longevity. This high-quality grease is the epitome of reliability and efficiency, making it a must-have for businesses seeking to optimize their machinery’s performance and minimize maintenance costs.

(VNOVO Powder Nickel-coated molybdenum disulfide grease Resistance high quality lithium-based grease)

FAQs of VNOVO Powder Nickel-coated molybdenum disulfide grease Resistance high quality lithium-based grease

Inquiry us