Overview of tungsten carbide powder WC 20(carbide)

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of tungsten carbide powder WC 20(carbide)

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

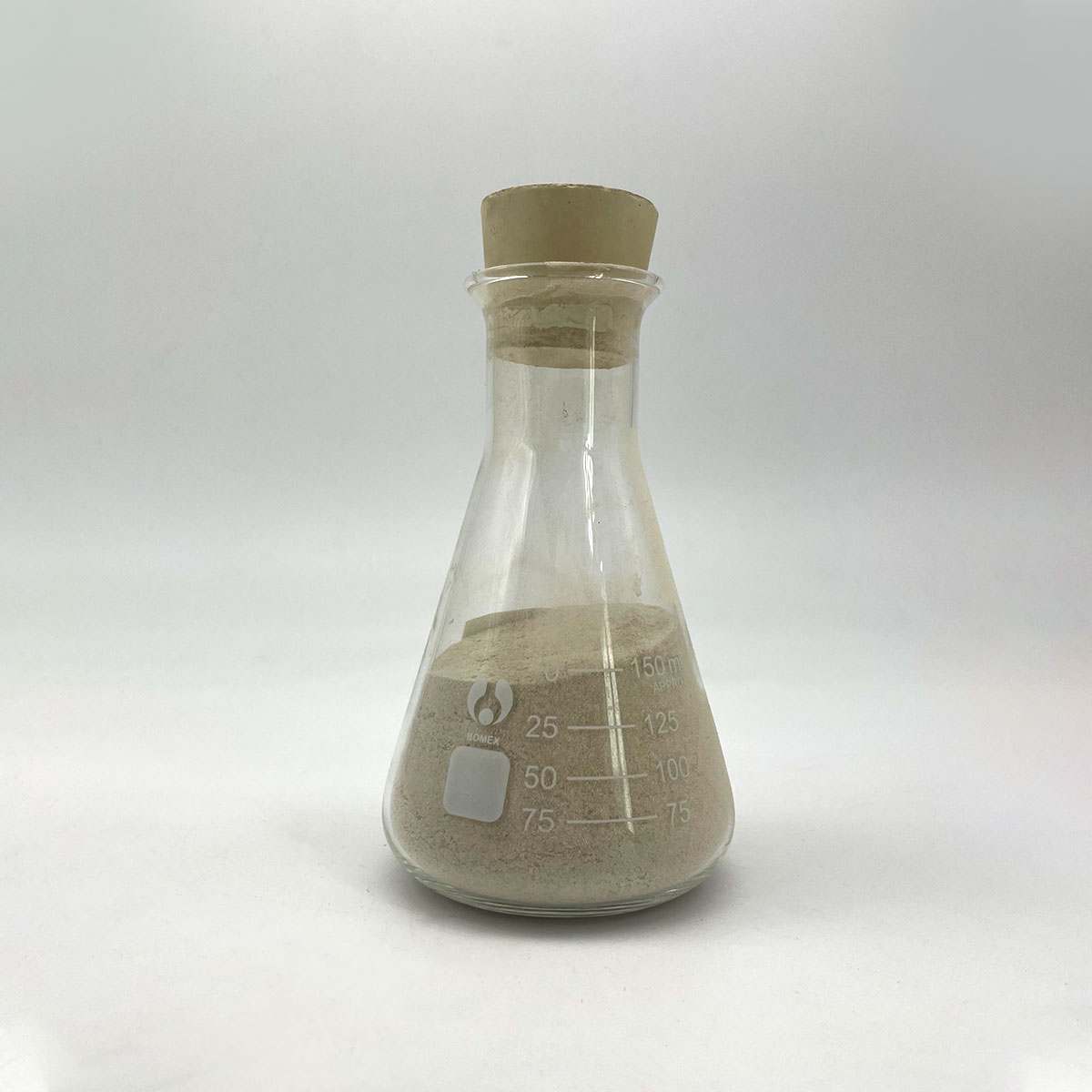

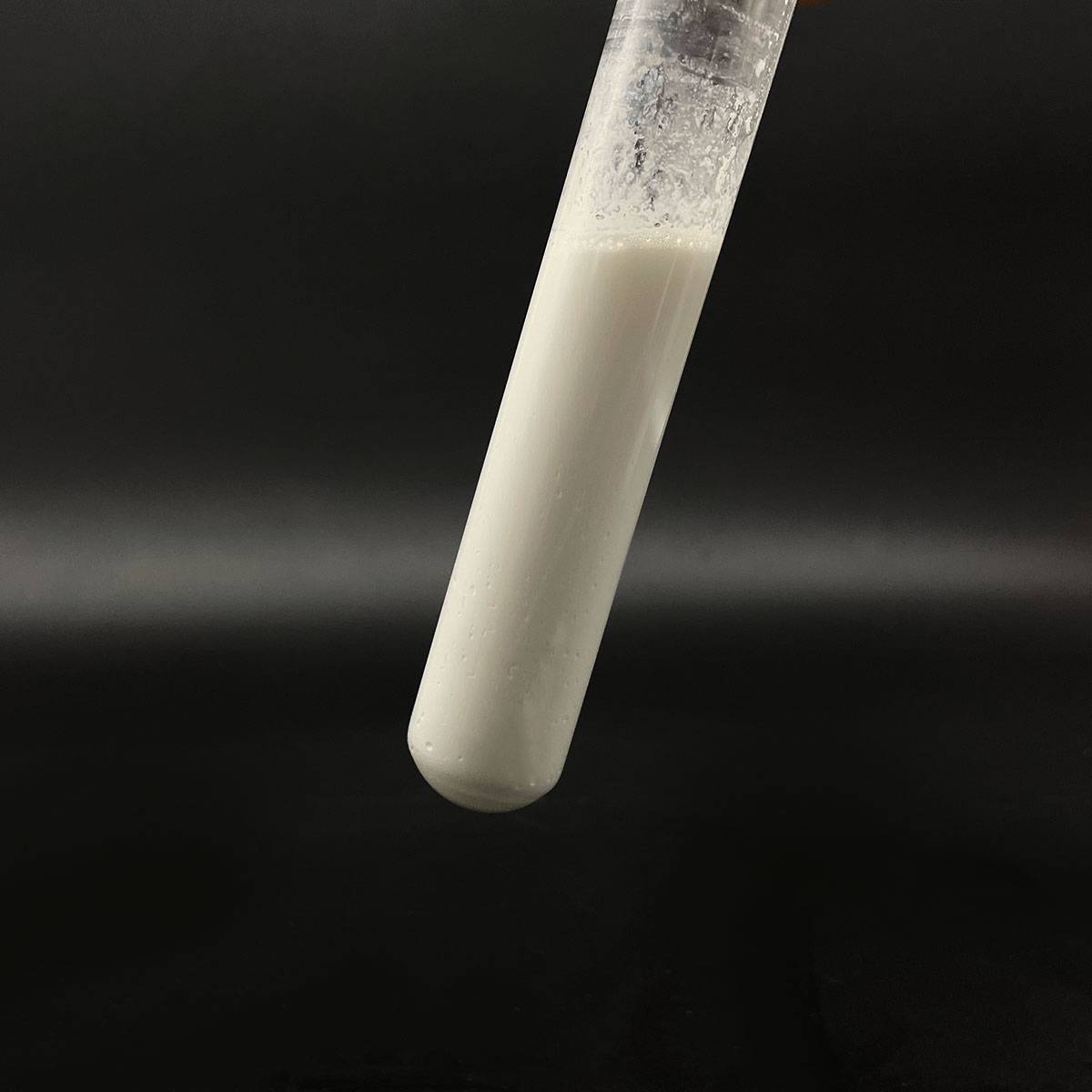

(tungsten carbide powder WC 20(carbide))

Parameters of tungsten carbide powder WC 20(carbide)

Tungsten carbide, often abbreviated as WC, is a high-performance material that finds extensive applications across various industries due to its exceptional properties. WC 20 (carbide), specifically, refers to a tungsten carbide grade with a tungsten content of 20% by weight, complemented by carbon as the primary binder material. This composition offers a unique blend of strength, hardness, and wear resistance, making it a popular choice in demanding environments.

Tungsten carbide is an intermetallic compound, formed by the chemical reaction between tungsten (W) and carbon (C). The high tungsten content in WC 20 ensures a dense structure, which contributes to its extraordinary mechanical properties. At 20%, it strikes a balance between toughness and rigidity, making it suitable for both wear-resistant and cutting applications.

One of the key features of WC 20 is its extreme hardness, measured on the Mohs scale, where tungsten carbide typically ranges from 8.5 to 9.5. This hardness makes it resistant to deformation under heavy loads and wear, making it ideal for use in tools and components subjected to abrasive or erosive forces. It is commonly used in the manufacturing of cutting tools, such as drill bits, end mills, and inserts, where its longevity and precision are crucial.

The combination of tungsten and carbon also enhances the thermal stability of WC 20, allowing it to maintain its hardness even at elevated temperatures. This property is particularly important in applications like high-temperature machining or in environments where thermal cycling occurs. Additionally, tungsten carbide has excellent chemical inertness, which prevents unwanted reactions with other materials and extends the tool’s lifespan.

WC 20 can be processed into various forms, including powders, granules, and sintered or bonded materials. The powder form is often used in powder metallurgy processes, where it is compacted or sintered under high pressure and temperature to create a solid, dense structure. This process allows for precise control over the microstructure and tailor-made properties for specific applications.

In terms of surface finish, tungsten carbide can be polished to achieve extremely smooth surfaces, which is crucial in precision engineering and semiconductor manufacturing. Furthermore, the material can be coated with other elements, such as cobalt or titanium, to enhance its wear resistance and improve tool life.

Despite its many advantages, tungsten carbide does have some limitations. It is brittle, which means it can crack under sudden impacts or high stress. To overcome this, manufacturers often combine it with other metals like cobalt or nickel to form cobalt-tungsten carbide (Co-WC) or nickel-tungsten carbide (Ni-WC) alloys, which offer better toughness while maintaining high hardness.

In conclusion, tungsten carbide powder WC 20 is a versatile material characterized by its exceptional hardness, wear resistance, and thermal stability. Its wide range of applications, from cutting tools to wear-resistant components, owes to its unique composition and processing capabilities. As technology advances, researchers continue to explore ways to optimize its performance further, ensuring that tungsten carbide remains a cornerstone material in modern industry.

(tungsten carbide powder WC 20(carbide))

FAQs of tungsten carbide powder WC 20(carbide)

Inquiry us