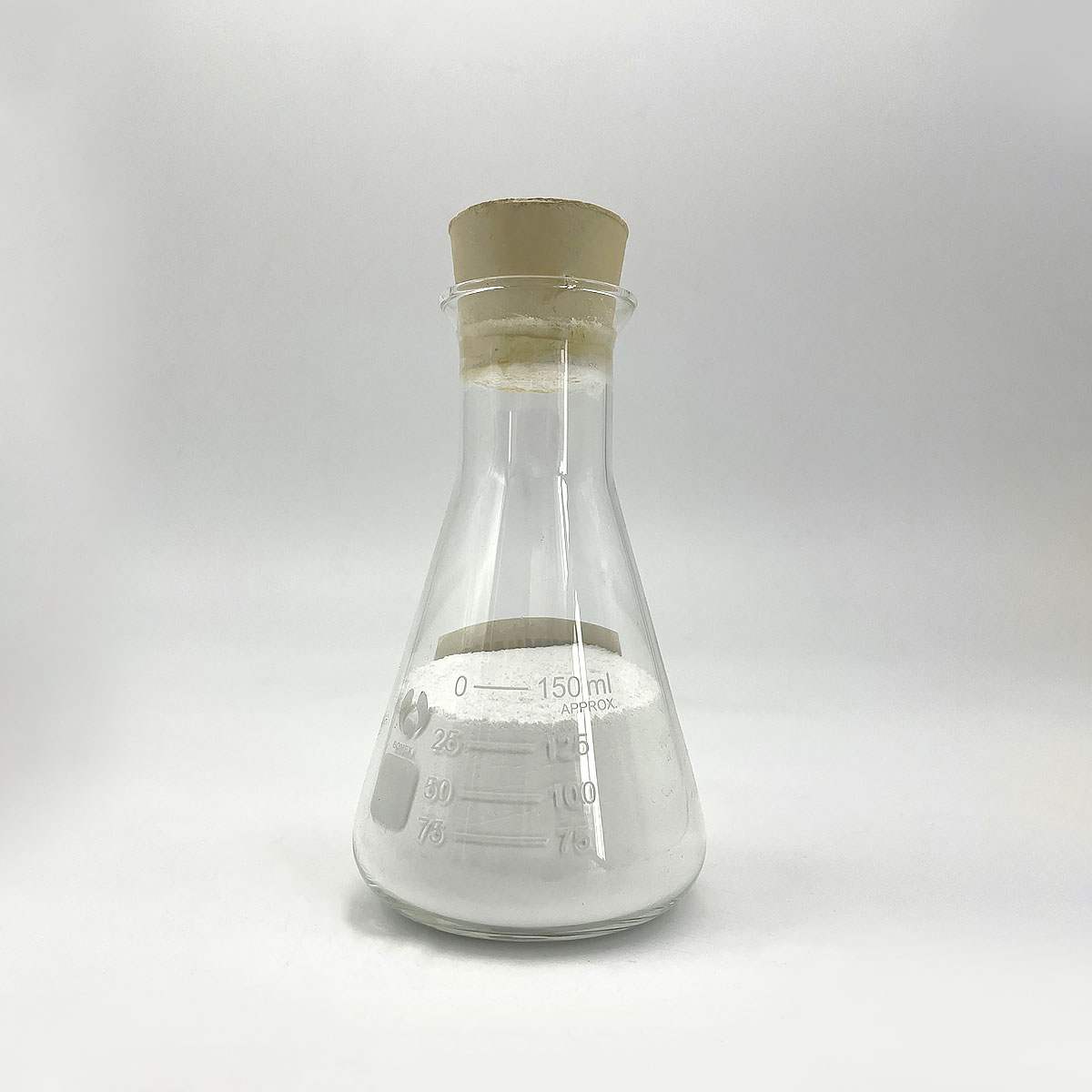

Overview of Tungsten Carbide Powder Tungsten Carbide Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Tungsten Carbide Powder Tungsten Carbide Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Tungsten Carbide Powder Tungsten Carbide Powder)

Parameters of Tungsten Carbide Powder Tungsten Carbide Powder

Tungsten Carbide Powder: A High-Performance Material in Modern Industry

Tungsten carbide, a remarkable material known for its exceptional hardness, wear resistance, and thermal stability, is an essential component in numerous industrial applications. Derived from the chemical combination of tungsten and carbon, tungsten carbide powder is a versatile form that offers unparalleled strength and durability when transformed into various shapes and forms.

Key Parameters of Tungsten Carbide Powder:

1. Composition: The primary constituents of tungsten carbide powder are tungsten (W) and carbon (C). Typically, the ratio of tungsten to carbon ranges from 95% to 98% for cemented carbides, while pure tungsten carbide powders can have a carbon content as low as 75%. The balance is often composed of cobalt (Co) as a binder or catalyst, which improves sintering properties.

2. Particle Size and Shape: Tungsten carbide powders are available in a wide range of particle sizes, typically measured in micrometers (μm) or nanometers (nm). Smaller particles result in finer grain structures, enhancing mechanical properties like hardness and wear resistance. Shapes can vary from spherical, irregular, or even nanostructured, depending on the manufacturing process.

3. Hardness: Tungsten carbide possesses one of the highest hardness ratings among all materials, surpassing steel and ceramics. This inherent hardness allows it to maintain its integrity under extreme cutting conditions, making it ideal for tools and wear-resistant components.

4. Density: With a high density of around 14.2 g/cm³, tungsten carbide powder ensures a dense, compact final product after sintering, which contributes to its excellent strength and stiffness.

5. Thermal Conductivity: Although not as high as metals, tungsten carbide has relatively good thermal conductivity, which helps dissipate heat generated during operations, preventing tool degradation.

6. Chemical Stability: Tungsten carbide is resistant to corrosion by most acids and alkalis, as well as to high temperatures. However, it can be attacked by strong reducing agents like hydrogen.

Applications of Tungsten Carbide Powder:

1. Cutting Tools: Tungsten carbide is widely used in the manufacturing industry for high-speed cutting tools, drill bits, and milling cutters due to its wear resistance and ability to maintain sharp edges.

2. Wear Parts: In machinery and equipment subjected to heavy wear, tungsten carbide is employed in bearings, pumps, and seals, extending their service life.

3. Coatings: As a coating material, tungsten carbide is applied to metal surfaces to improve wear resistance, friction, and wear life in various applications, such as automotive, aerospace, and mining.

4. Electronic Components: Tungsten carbide is used in microelectromechanical systems (MEMS) and semiconductor manufacturing due to its high hardness and thermal stability.

5. Dental Implants: Due to its biocompatibility and wear resistance, tungsten carbide is utilized in dental implants and orthodontic appliances.

In conclusion, tungsten carbide powder is a game-changer in modern industry, offering exceptional performance in demanding applications. Its unique combination of hardness, wear resistance, and thermal stability make it indispensable in various sectors, from manufacturing to healthcare. With ongoing advancements in particle size control and sintering techniques, tungsten carbide powder continues to evolve, opening up new possibilities for innovation and efficiency.

(Tungsten Carbide Powder Tungsten Carbide Powder)

FAQs of Tungsten Carbide Powder Tungsten Carbide Powder

Inquiry us