Overview of Titanium Aluminum Vanadium alloy Ti6Al4V powder for 3D Printing

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Titanium Aluminum Vanadium alloy Ti6Al4V powder for 3D Printing

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

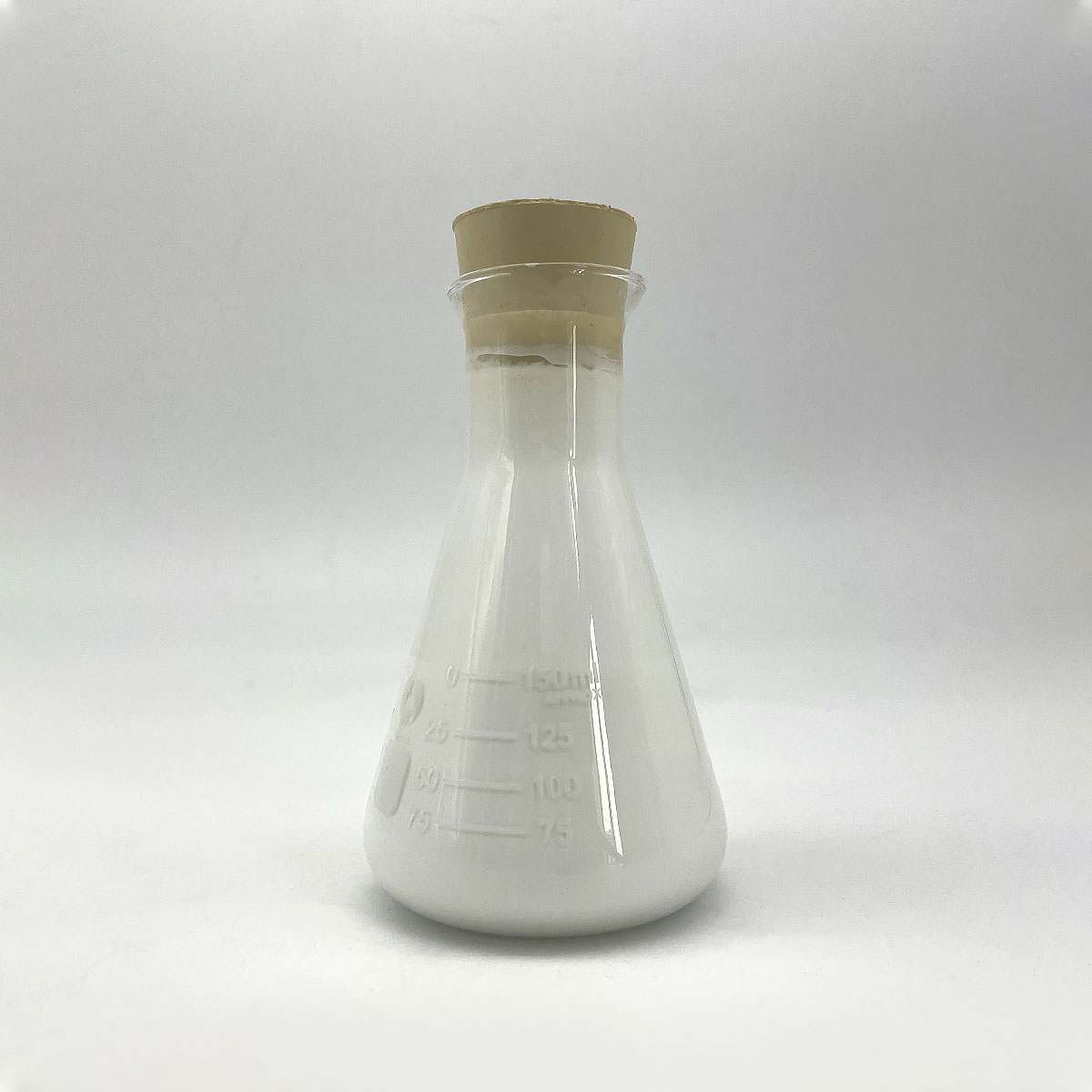

(Titanium Aluminum Vanadium alloy Ti6Al4V powder for 3D Printing)

Parameters of Titanium Aluminum Vanadium alloy Ti6Al4V powder for 3D Printing

Titanium Aluminum Vanadium (Ti6Al4V) is a widely recognized and versatile aerospace-grade alloy, particularly popular in the realm of 3D printing due to its exceptional mechanical properties and biocompatibility. This specific alloy is composed of approximately 6% aluminum, 4% vanadium, and the remainder being titanium, with trace amounts of other elements like iron, carbon, and oxygen.

Ti6Al4V powder, used for 3D printing, offers several key attributes that make it an ideal choice for various applications. Firstly, its high strength-to-weight ratio makes it suitable for lightweight components in industries such as aerospace, automotive, and medical devices. The alloy’s corrosion resistance, both in air and under water, ensures long-term durability without the need for protective coatings.

The powder’s particle size distribution plays a crucial role in achieving optimal print quality. Ti6Al4V powders typically have a narrow size range, which results in better layer adhesion and fewer defects during the printing process. This allows for the creation of intricate geometries and smooth surfaces that are essential for functional and aesthetic purposes.

The alloy’s thermal conductivity and heat capacity are important factors in controlling the printing temperature and ensuring proper part cooling. Ti6Al4V requires relatively high build temperatures, often in the range of 600-1000°C, to achieve full fusion during the sintering process. However, this also necessitates advanced 3D printers capable of handling these elevated temperatures without damage.

One of the most notable features of Ti6Al4V is its biocompatibility, making it suitable for applications in orthopedic implants and dental prosthetics. The alloy’s ability to integrate well with living tissue and its low wear rate contribute to its popularity in medical 3D printing.

In terms of printing parameters, the specific settings can vary depending on the chosen 3D printer and the desired part characteristics. Key parameters include layer thickness, infill density, print speed, and support structure generation. For instance, a lower layer height may result in smoother prints, while a higher infill density would provide increased structural integrity. The use of a fine-powdered Ti6Al4V often requires slower print speeds to ensure proper bonding between particles.

Powder-bed fusion processes, like Selective Laser Melting (SLM) or Electron Beam Melting (EBM), are commonly employed for 3D printing Ti6Al4V due to their ability to handle the high melting point and create fully dense parts. These methods require precise control over laser power, scanning strategy, and gas shielding to prevent oxidation and maintain the alloy’s desirable properties.

In conclusion, Ti6Al4V alloy powder for 3D printing is a high-performance material that combines strength, lightweight nature, corrosion resistance, and biocompatibility. Its successful application in various industries depends on optimizing the printing parameters to achieve the desired part quality, mechanical properties, and surface finish. As research and technology continue to evolve, Ti6Al4V is poised to revolutionize more areas where lightweight, durable, and customized components are essential.

(Titanium Aluminum Vanadium alloy Ti6Al4V powder for 3D Printing)

FAQs of Titanium Aluminum Vanadium alloy Ti6Al4V powder for 3D Printing

Inquiry us