Overview of Tantalum Carbide Powder minerals&metallurgy powder series

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Tantalum Carbide Powder minerals&metallurgy powder series

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

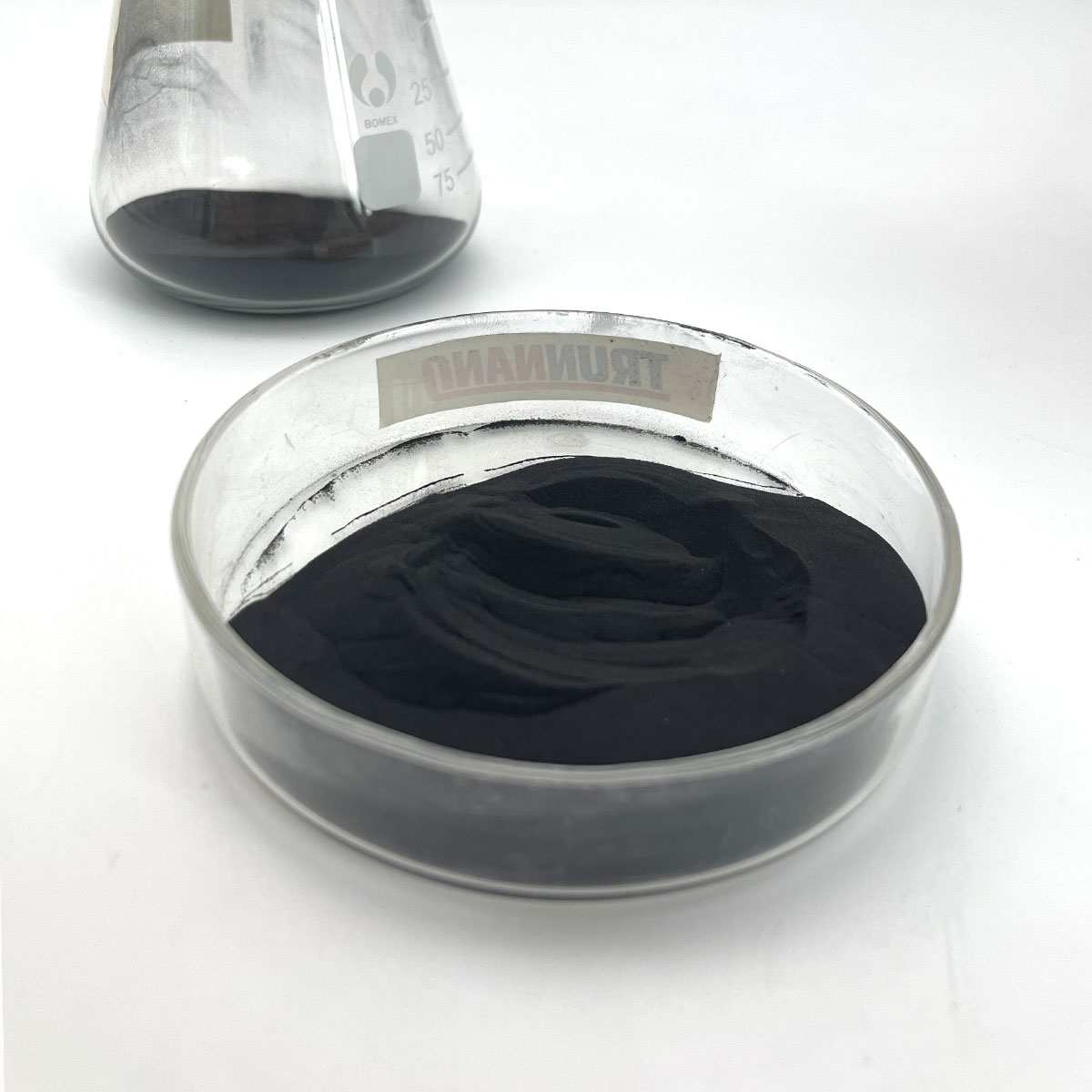

(Tantalum Carbide Powder minerals&metallurgy powder series)

Parameters of Tantalum Carbide Powder minerals&metallurgy powder series

Tantalum Carbide (TaC) Powder: A High-Performance Material in Minerals and Metallurgy

Tantalum carbide, a compound of tantalum and carbon, is an exceptional material with extraordinary properties that make it indispensable in various sectors of the minerals and metallurgy industry. This advanced ceramic material stands out due to its unique combination of strength, hardness, wear resistance, and thermal stability.

1. Composition: Tantalum carbide consists of approximately 80-90% tantalum and 10-20% carbon, depending on the specific grade required for different applications. The high carbon content contributes to its exceptional hardness and wear resistance, while the tantalum provides inherent corrosion resistance and high melting point.

2. Crystal Structure: TaC exists primarily in a hexagonal structure, known as the α-form, which imparts excellent mechanical properties. The close-packed arrangement of atoms in this crystal lattice enhances its strength and stiffness, making it suitable for demanding applications where durability is crucial.

3. Hardness and Abrasion Resistance: Tantalum carbide powder exhibits an extremely high hardness, often measured in the Vickers hardness scale above 25 GPa, which is higher than that of most metals. This makes it ideal for use in extreme environments where wear and abrasion are significant factors, such as cutting tools, coatings, and bearings.

4. Thermal Stability: TaC maintains its integrity at high temperatures, with a melting point around 3000°C, making it suitable for applications where thermal resistance is critical. It shows minimal thermal expansion, ensuring dimensional stability even under elevated conditions.

5. Electrical Conductivity: Although primarily a ceramic material, tantalum carbide possesses a moderate level of electrical conductivity, which is beneficial in applications like electrical contacts, heat sinks, and high-temperature switches.

6. Chemical Stability: Tantalum carbide is highly resistant to chemical attack, including corrosion from acids and alkalis, making it an ideal choice for chemical processing equipment and aerospace components.

7. Processing Techniques: Tantalum carbide powders can be produced using various methods, including mechanical milling, sintering, or chemical vapor deposition (CVD). These processes allow for customization of particle size, morphology, and surface finish, catering to the diverse requirements of different industries.

8. Applications: The versatility of tantalum carbide powder extends across a broad range of industries, including automotive, aerospace, oil and gas, mining, and electronics. It finds use in cutting tools, wear-resistant coatings, heat exchangers, high-speed drilling bits, and even as a substitute for tungsten carbide in certain applications.

In conclusion, tantalum carbide powder is a premium material offering unparalleled performance in the face of extreme conditions. Its unique properties make it a sought-after component in the minerals and metallurgy sector, driving innovation and enabling the development of advanced technologies across multiple industries. As research and technology continue to evolve, the potential applications for tantalum carbide will only expand, solidifying its position as a key material in the modern industrial landscape.

(Tantalum Carbide Powder minerals&metallurgy powder series)

FAQs of Tantalum Carbide Powder minerals&metallurgy powder series

Inquiry us