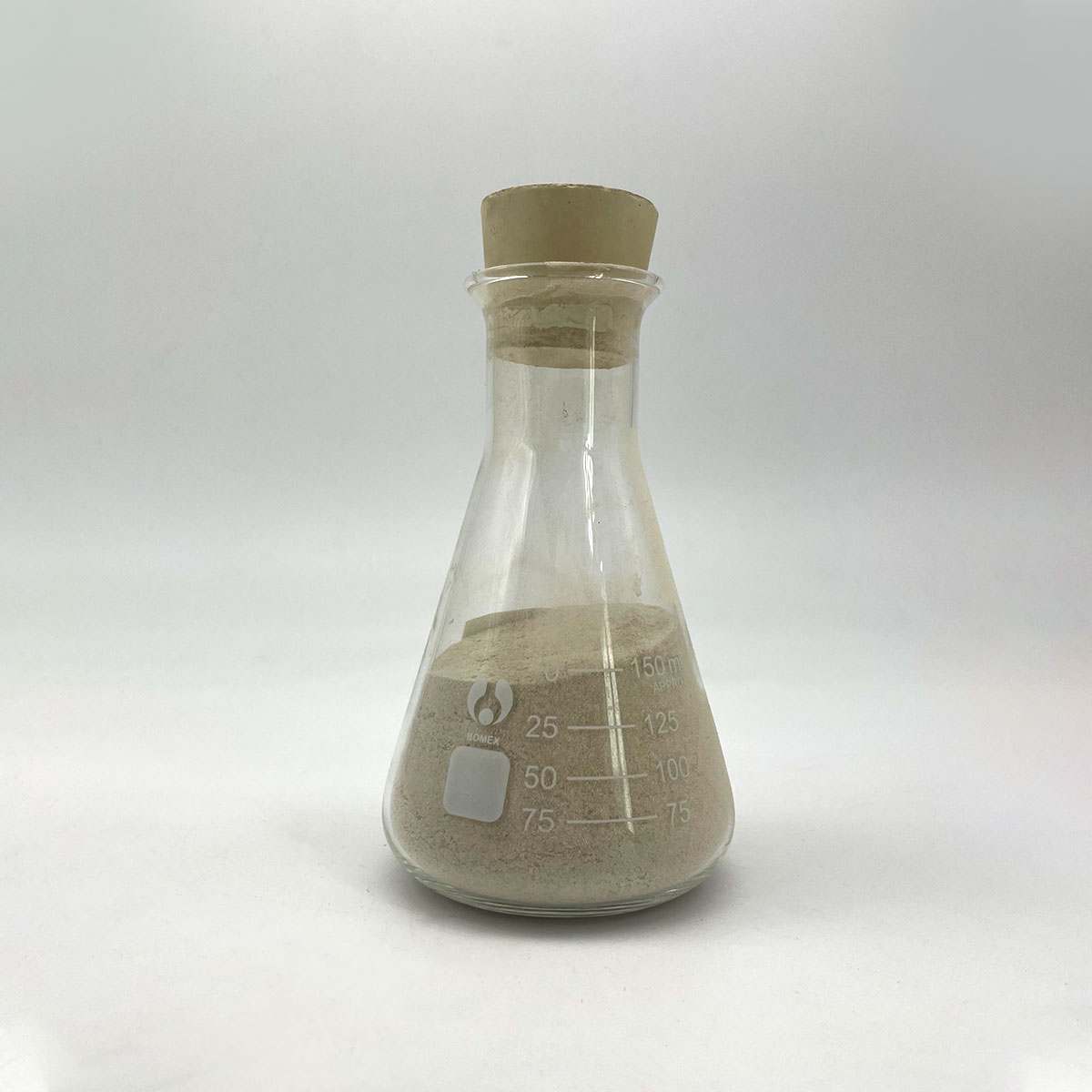

Overview of Supply TiB2 powder cas 12045-63-5 Titanium boride powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Supply TiB2 powder cas 12045-63-5 Titanium boride powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Supply TiB2 powder cas 12045-63-5 Titanium boride powder )

Parameters of Supply TiB2 powder cas 12045-63-5 Titanium boride powder

Titanium Boride (TiB2) Powder: A High-Performance Material for Advanced Applications

Titanium boride (TiB2), also known as rhenium diboride, is a compound with the chemical formula TiB2 and the CAS number 12045-63-5. This unique material possesses exceptional properties that make it a sought-after component in various industries, including aerospace, electronics, and energy production. As a fine powder, TiB2 offers versatility and adaptability in its applications, thanks to its inherent characteristics.

First and foremost, TiB2 is a refractory ceramic material, which means it has an extremely high melting point of around 3423°C (6491°F). This exceptional thermal stability makes it ideal for applications where resistance to extreme heat is crucial, such as in high-temperature environments or as a protective coating for components subjected to intense heat flux.

The material’s hardness is another standout feature. TiB2 boasts a Mohs hardness of 8.5, rivaling that of diamond, making it extremely resistant to wear and tear. This durability ensures long-lasting performance in applications like cutting tools, grinding wheels, and wear-resistant coatings for machinery components.

In addition to its mechanical strength, TiB2 exhibits excellent electrical and thermal conductivity. It has a low electrical resistivity, making it suitable for use in electronic components and conductive coatings. Its thermal conductivity is also quite high, which aids in efficient heat dissipation, an essential property for electronic devices and heat management systems.

The material’s chemical inertness is another key advantage. TiB2 resists corrosion from most acids, alkalis, and molten metals, making it an ideal choice for applications where chemical resistance is critical. This durability extends to high-temperature environments where exposure to corrosive substances can be detrimental to other materials.

Furthermore, TiB2 possesses a high melting point and low coefficient of thermal expansion, which results in excellent dimensional stability. This property is crucial for applications like precision ceramics, semiconductor manufacturing, and optical components where dimensional accuracy is paramount.

Processing TiB2 powder into various forms, such as sintered parts, composite materials, or coatings, allows engineers to tailor its properties for specific applications. Its compatibility with other materials, including metals and ceramics, enables the development of composite structures that combine the best attributes of each component.

In the field of aerospace, TiB2 finds application in lightweight, high-strength components for aircraft engines and turbines. Its lightweight nature and high thermal stability contribute to improved fuel efficiency and overall system performance. In the electronics industry, it is used in high-power devices, where its electrical and thermal conductivity play a vital role in heat dissipation and reliability.

In conclusion, TiB2 powder (CAS number 12045-63-5) is a remarkable material due to its combination of high temperature stability, hardness, electrical conductivity, chemical inertness, and dimensional stability. Its versatile properties make it a valuable component in numerous industries, from aerospace to electronics, where demanding conditions require materials that can withstand the test of time and perform under pressure. As research and development continue to advance, the potential applications for TiB2 powder are likely to expand even further.

(Supply TiB2 powder cas 12045-63-5 Titanium boride powder )

FAQs of Supply TiB2 powder cas 12045-63-5 Titanium boride powder

Inquiry us