Overview of Supply high purity 99.9% tungsten carbide wc metal powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Supply high purity 99.9% tungsten carbide wc metal powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

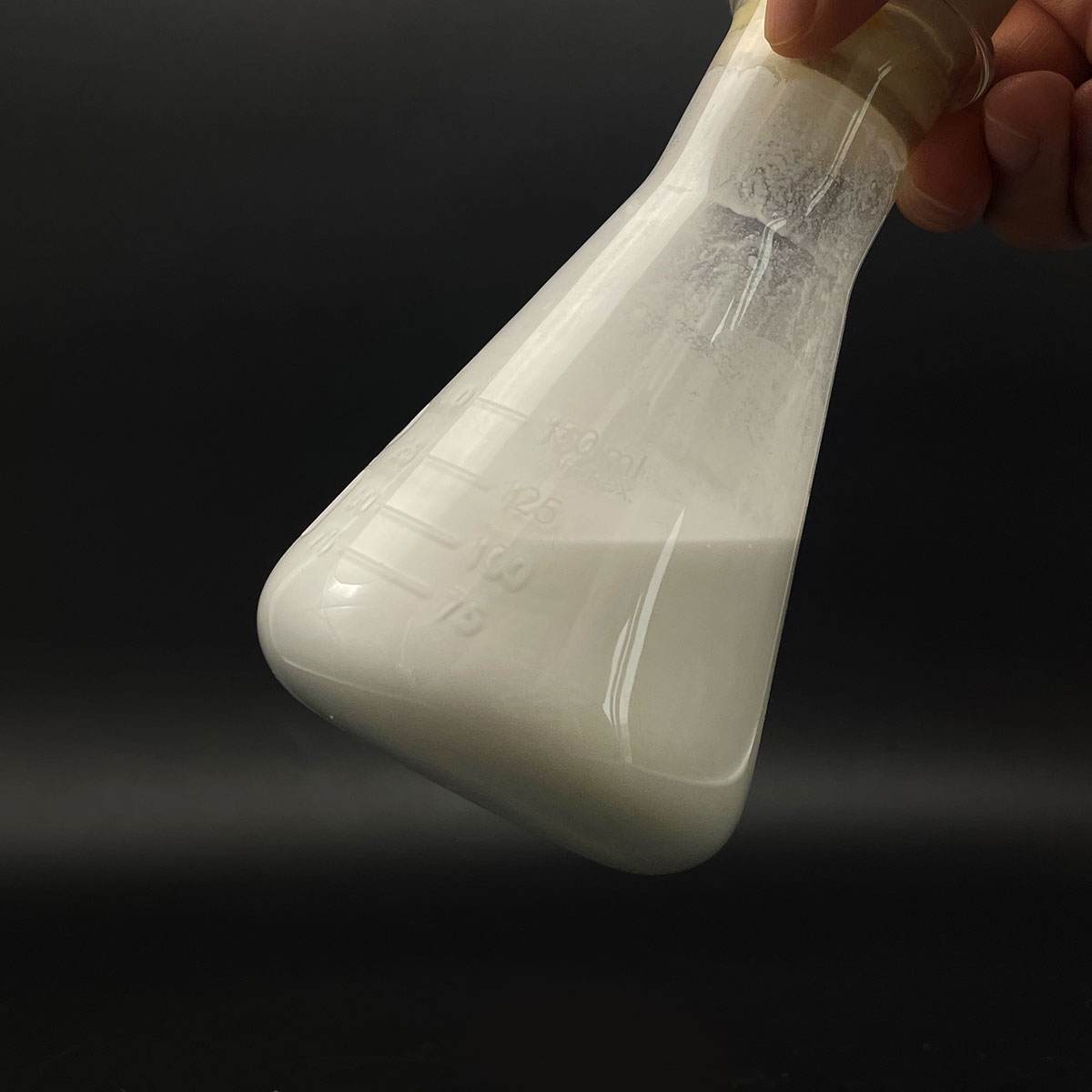

(Supply high purity 99.9% tungsten carbide wc metal powder)

Parameters of Supply high purity 99.9% tungsten carbide wc metal powder

Tungsten Carbide (WC), also known as W-C or WC-Co, is a high-performance material that combines the exceptional strength and hardness of tungsten with the lubricity and wear resistance of carbon. It is a popular choice in various industries due to its extraordinary properties, making it suitable for applications requiring extreme durability and precision.

High Purity 99.9% Tungsten Carbide WC Metal Powder Specifications:

1. Chemical Composition: The primary component is tungsten (W) with a purity level of 99.9%, ensuring a near-perfect balance between tungsten and carbon. This high purity allows for consistent performance and minimal impurities that could affect the material’s properties.

2. Particle Size Distribution: Our metal powder offers a narrow size distribution, typically ranging from 30 microns to 75 microns, providing a uniform blend for efficient processing and integration into various materials. Custom particle sizes can also be tailored upon request to meet specific application requirements.

3. Morphology: The WC particles exhibit a spherical or sub-spherical shape, which promotes better flowability and packing density during compaction or sintering processes. This morphology contributes to improved mechanical properties in the final product.

4. Hardness: With a Vickers hardness of over 2500 HV, tungsten carbide is one of the hardest materials available. This hardness makes it resistant to wear and tear, ideal for use in high-stress environments like cutting tools, wear-resistant coatings, and bearings.

5. Thermal Conductivity: Tungsten carbide has excellent thermal conductivity, which helps dissipate heat efficiently, preventing premature tool failure and maintaining optimal operating temperatures.

6. Chemical Stability: Tungsten carbide is chemically inert, resistant to corrosion by most acids and alkalis, and exhibits low affinity for oxygen and moisture. This stability ensures long-term performance in corrosive environments.

7. Coatings: Optionally, our WC powder can be alloyed with cobalt (Co) to form WC-Co composites, which enhance toughness and reduce brittleness, making them suitable for applications requiring both hardness and impact resistance.

8. Processing: The 99.9% pure tungsten carbide powder is compatible with various manufacturing techniques, such as powder metallurgy, sintering, and hot pressing. These processes enable the creation of intricate shapes and components with precise dimensions.

9. Applications: The versatility of tungsten carbide powder enables its use across numerous industries, including aerospace, automotive, mining, and manufacturing. Common applications include cutting tools, wear-resistant coatings on machine parts, and high-speed drill bits.

In conclusion, our 99.9% pure tungsten carbide metal powder is a premium material characterized by its exceptional strength, hardness, and chemical stability. Its tailored particle size distribution and spherical morphology make it an ideal choice for demanding applications where durability, precision, and resistance to wear are paramount. With its wide range of processing capabilities and compatibility with various industries, tungsten carbide continues to be a cornerstone material in modern technology.

(Supply high purity 99.9% tungsten carbide wc metal powder)

FAQs of Supply high purity 99.9% tungsten carbide wc metal powder

Inquiry us