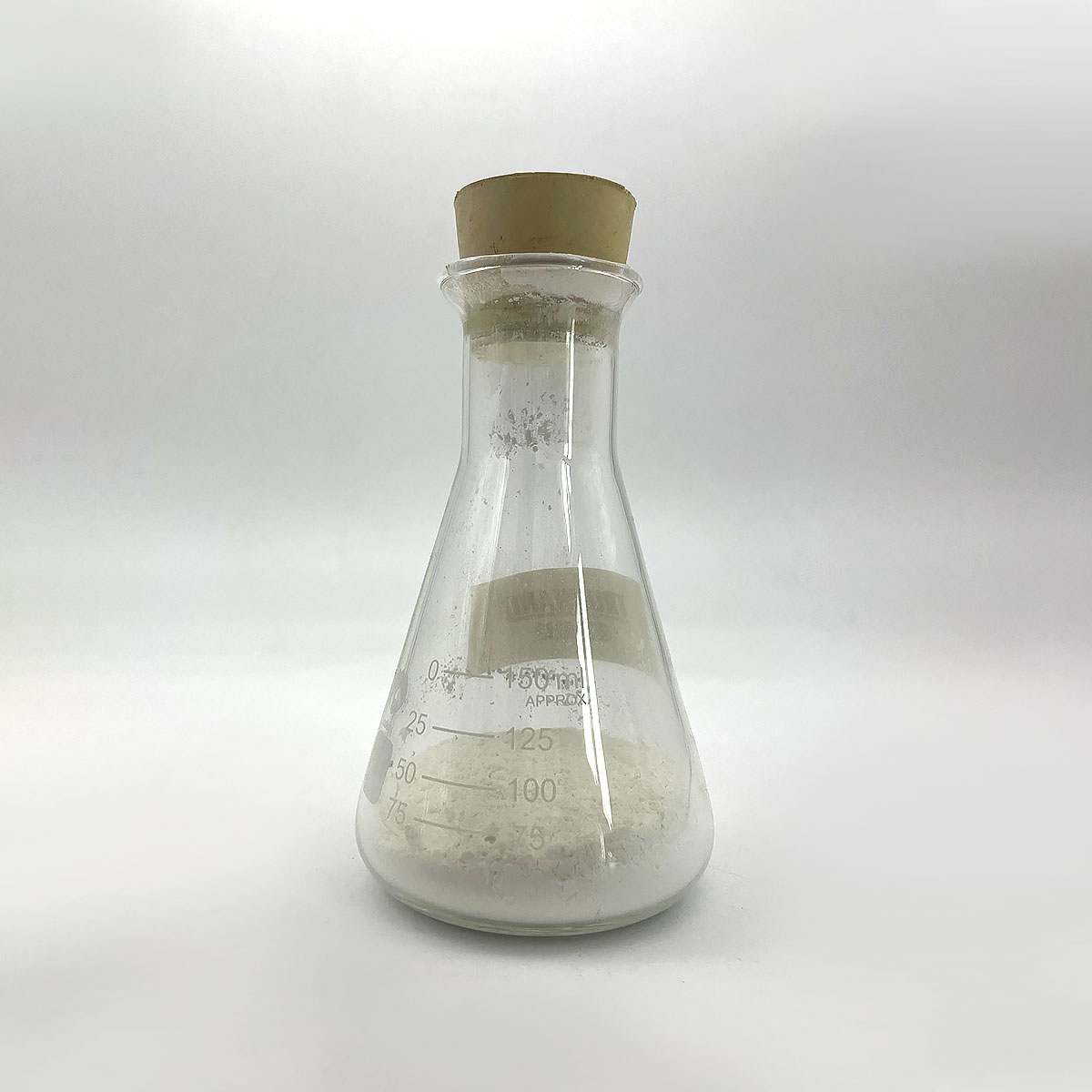

Overview of Sodium Molybdate Dihydrate For Molybdenum-Containing Catalysts Other Molybdates And Molybdenum

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Sodium Molybdate Dihydrate For Molybdenum-Containing Catalysts Other Molybdates And Molybdenum

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Sodium Molybdate Dihydrate For Molybdenum-Containing Catalysts Other Molybdates And Molybdenum)

Parameters of Sodium Molybdate Dihydrate For Molybdenum-Containing Catalysts Other Molybdates And Molybdenum

Sodium molybdate dihydrate, also known as sodium tetramolybdophosphate decahydrate (Na2MoO4·10H2O), is an essential compound in the realm of chemical catalysts, particularly those involving molybdenum. Molybdenum, a transition metal, plays a vital role in various industrial processes due to its exceptional redox properties and ability to form stable complexes with organic molecules.

Molybdate-based catalysts are widely used in different sectors such as petrochemicals, fine chemicals, pharmaceuticals, and environmental remediation. One of their key applications is in the hydrodesulfurization (HDS) process, where they help remove sulfur compounds from crude oil, making it suitable for cleaner combustion and refining. The presence of molybdenum in these catalysts enables selective hydrogenation reactions that minimize the formation of by-products like mercaptans.

Another significant application is in the production of polyurethanes, where sodium molybdate dihydrate is employed as a catalyst in the isocyanate polymerization reaction. It promotes the formation of urethane linkages, resulting in the desired thermosetting polymer.

In the field of water treatment, molybdate ions can be used as antimicrobial agents, particularly against bacteria and certain types of algae. They form stable complexes with heavy metals, facilitating their removal from water sources and preventing contamination.

The sodium molybdate dihydrate compound itself has a unique crystal structure, which contributes to its catalytic properties. Its high surface area allows for better dispersion of the molybdenum center, enhancing its interaction with reactants. The hydration state, with ten water molecules attached, is crucial as it influences the stability and reactivity of the compound.

However, it is essential to consider the parameters affecting the performance of molybdate catalysts. These include the molar ratio of sodium to molybdenum, temperature, pressure, and the choice of ligands or supporting materials. Optimal conditions must be determined experimentally to achieve the highest catalyst efficiency and selectivity.

Furthermore, the stability of sodium molybdate dihydrate under operating conditions is a concern. Prolonged exposure to heat, humidity, or aggressive chemicals can lead to dehydrogenation or decomposition, reducing its effectiveness. Therefore, proper storage and handling practices are necessary to maintain the catalyst’s integrity.

In conclusion, sodium molybdate dihydrate is a versatile and indispensable component in molybdenum-containing catalysts. Its unique properties and wide range of applications highlight its importance in various industries. Understanding the factors influencing its performance and addressing challenges related to stability are crucial for optimizing the efficiency and sustainability of these catalysts in modern chemical processes.

(Sodium Molybdate Dihydrate For Molybdenum-Containing Catalysts Other Molybdates And Molybdenum)

FAQs of Sodium Molybdate Dihydrate For Molybdenum-Containing Catalysts Other Molybdates And Molybdenum

Inquiry us