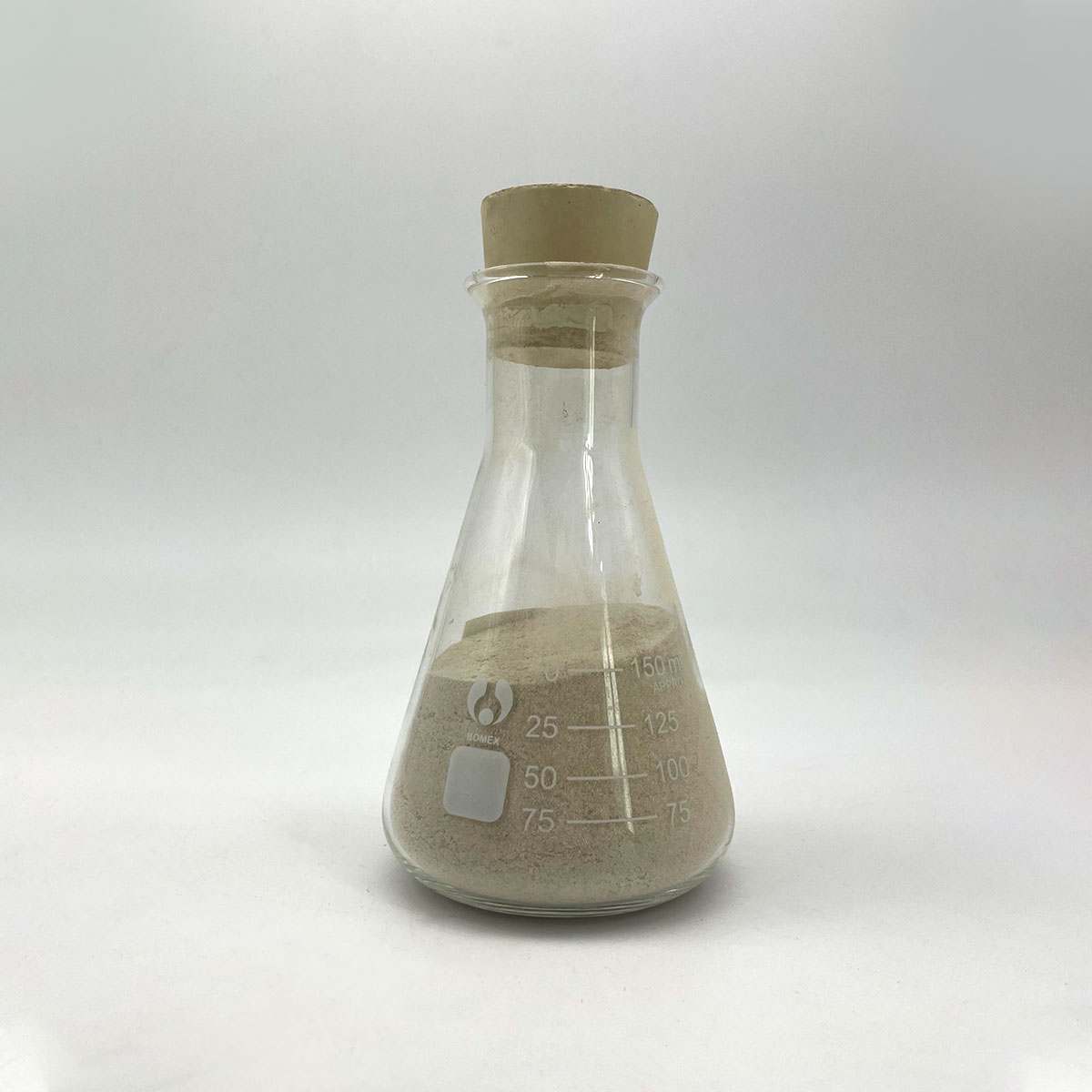

Overview of Round shape Titanium sputtering target vacuum coating material 2N5 purity customized size

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Round shape Titanium sputtering target vacuum coating material 2N5 purity customized size

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Round shape Titanium sputtering target vacuum coating material 2N5 purity customized size)

Parameters of Round shape Titanium sputtering target vacuum coating material 2N5 purity customized size

Title: Customized Round Shape Titanium Sputtering Target for Vacuum Coating with 2N5 Purity – Technical Specifications

Introduction:

Our cutting-edge technology enables the production of high-quality, round-shaped titanium sputtering targets, specifically designed for vacuum coating applications. These targets boast an exceptional purity level of 2N5, ensuring superior performance and consistent results in various industrial processes. With our customization capabilities, we cater to the unique needs of our clients, providing tailored solutions that meet their exact requirements.

Material:

The core material is 99.9999% pure titanium (2N5), which is the highest achievable purity grade for titanium. This ultra-high purity ensures minimal contamination during the sputtering process, resulting in a smooth, dense film deposition with excellent adhesion and optimal properties for the end product.

Shape:

The target is engineered in a round shape, allowing for efficient use of energy and minimized stress during operation. The cylindrical design facilitates even distribution of sputtering particles, enabling uniform coating thickness across the substrate. The diameter can be customized to accommodate various substrate sizes, ranging from standard options to bespoke dimensions as per client specifications.

Surface Finish:

Careful attention is given to the surface finish, ensuring a mirror-like finish that promotes efficient ionization and optimal sputtering efficiency. This is achieved through advanced polishing techniques, resulting in a smooth, flat surface without any defects or roughness that could affect the quality of the deposited layer.

Size Variations:

We offer a wide range of sizes, from standard sizes commonly used in the industry to custom sizes tailored to individual customer needs. The diameter can vary between 10mm to 500mm, and beyond, depending on the specific application and requirements. Our team works closely with clients to determine the most suitable size for their vacuum coating setup.

Thermal Properties:

Titanium’s inherent thermal stability ensures that the sputtering target maintains its integrity under high temperatures during the coating process. The heat conductivity and low coefficient of thermal expansion minimize temperature gradients, promoting consistent and reliable performance over time.

Customization Options:

In addition to the round shape and purity level, we provide a range of customization options to cater to diverse requirements. These may include surface treatments, such as plasma cleaning or nitriding, as well as custom packaging and handling to ensure safe transportation and storage.

Conclusion:

Our round shape titanium sputtering targets with 2N5 purity are the epitome of precision and reliability in vacuum coating applications. By offering customizable sizes and various additional features, we strive to deliver a tailored solution that meets the exact needs of our clients. Trust us to elevate your vacuum coating processes with our superior materials and expertise.

(Round shape Titanium sputtering target vacuum coating material 2N5 purity customized size)

FAQs of Round shape Titanium sputtering target vacuum coating material 2N5 purity customized size

Inquiry us