Overview of Pure 99.95% Pure Molybdenum Mo Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Pure 99.95% Pure Molybdenum Mo Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

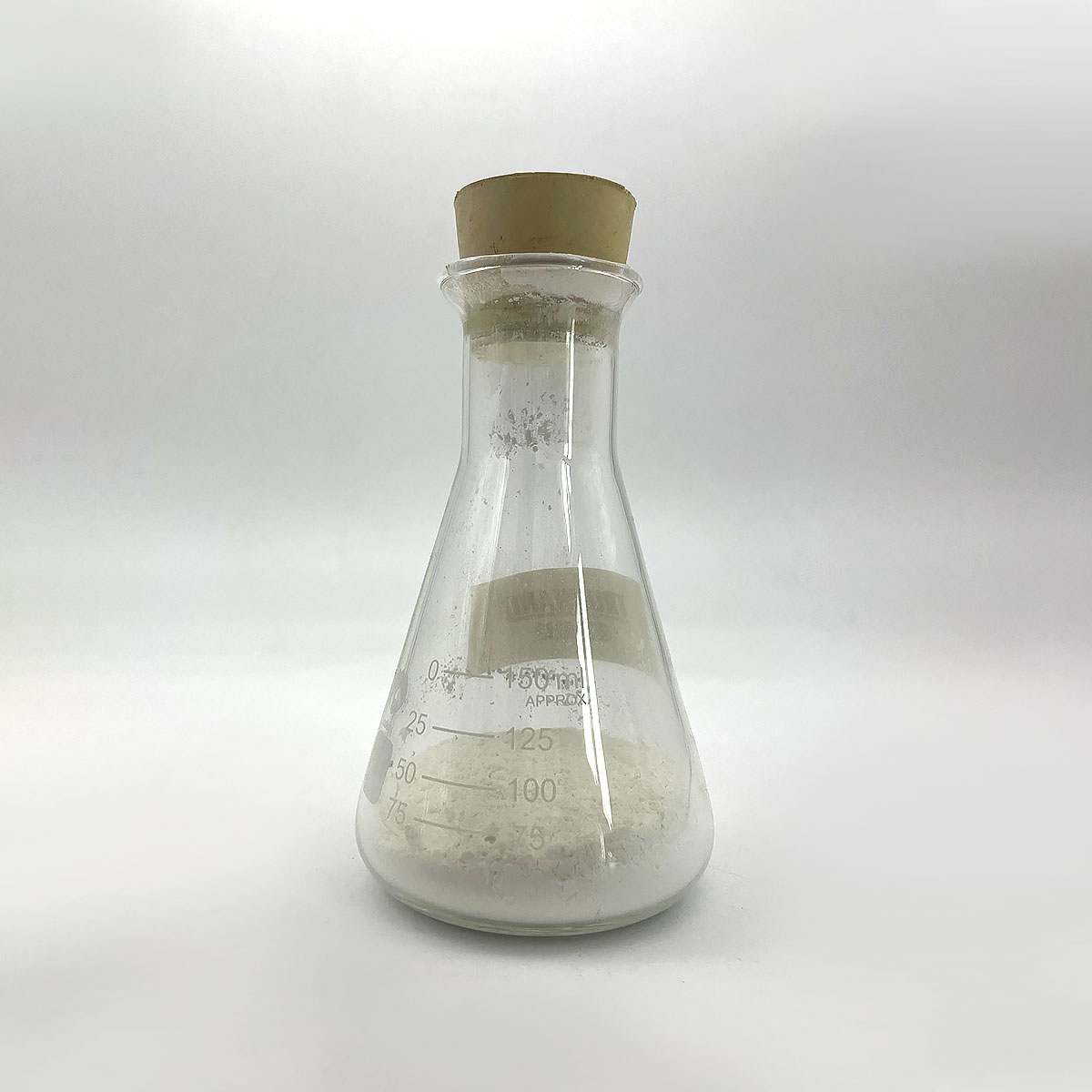

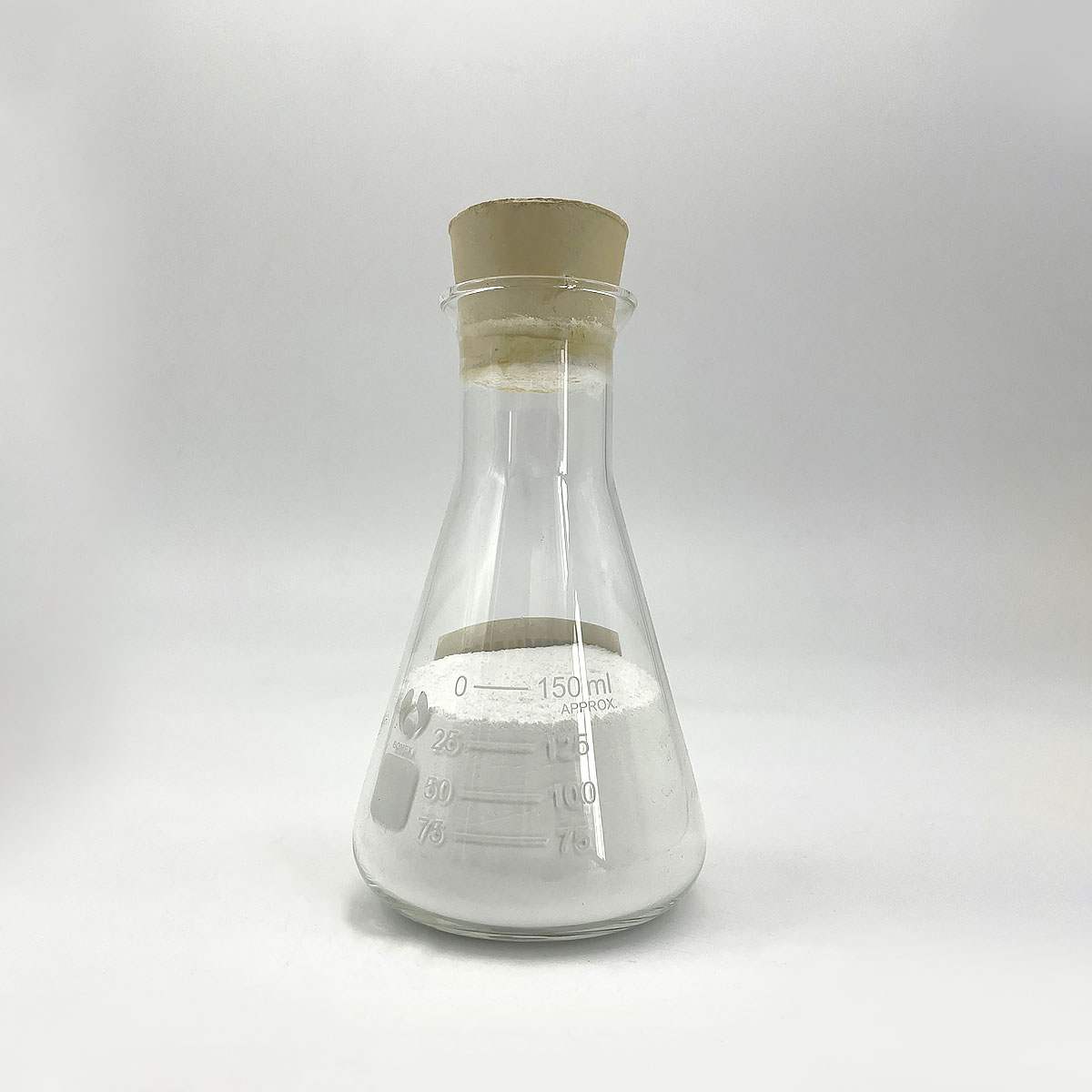

(Pure 99.95% Pure Molybdenum Mo Powder)

Parameters of Pure 99.95% Pure Molybdenum Mo Powder

Molybdenum, with the chemical symbol Mo, is a ductile and lustrous transition metal that holds significant importance in various industries due to its exceptional properties. The 99.95% pure molybdenum powder you are referring to is a high-purity form of this element, widely used for its unique combination of strength, corrosion resistance, and thermal stability.

At 99.95% purity, this molybdenum powder exhibits an almost flawless composition, making it ideal for demanding applications where impurities can compromise performance. The purity level ensures minimal contamination, which is crucial when dealing with materials like molybdenum, which is often employed in critical components such as jet engine parts, nuclear reactors, and chemical processing equipment.

The powder’s particle size is carefully controlled to provide consistent performance and compatibility with various manufacturing processes. Depending on the application, the powder may be produced in different grain sizes, ranging from sub-micron to larger particles, each tailored to meet specific requirements for sintering or melting.

Molybdenum’s high melting point (2623°C) allows it to withstand extreme temperatures, making it suitable for applications where heat resistance is vital. Its low coefficient of thermal expansion reduces the likelihood of dimensional changes under temperature fluctuations, which is highly desirable in aerospace and automotive industries.

The material’s excellent wear resistance and low coefficient of friction make it ideal for bearings, gears, and other sliding surfaces. Molybdenum also possesses superior creep strength, maintaining its integrity over extended periods under high pressure, making it ideal for use in power generation and heavy machinery.

In addition to these mechanical properties, molybdenum is known for its excellent corrosion resistance, particularly against acids and alkalis. This makes it an ideal choice for applications in harsh environments, such as oil and gas exploration, chemical processing, and marine engineering.

Processing this pure molybdenum powder involves techniques like argon gas atomization, milling, or sintering, which result in a fine, homogeneous dispersion of the metal. These processes ensure the desired purity while maintaining the material’s inherent characteristics.

In conclusion, the 99.95% pure molybdenum powder is a versatile material with exceptional properties, including strength, durability, and corrosion resistance. Its high purity and customizable particle size make it a preferred choice for industries ranging from aerospace to energy production, where reliability and performance are paramount. By understanding and utilizing these attributes, manufacturers can harness the full potential of this extraordinary metal in their products and processes.

(Pure 99.95% Pure Molybdenum Mo Powder)

FAQs of Pure 99.95% Pure Molybdenum Mo Powder

Inquiry us