Overview of Niobium block pure Niobium metal High purity Niobium ingot

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Niobium block pure Niobium metal High purity Niobium ingot

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Niobium block pure Niobium metal High purity Niobium ingot)

Parameters of Niobium block pure Niobium metal High purity Niobium ingot

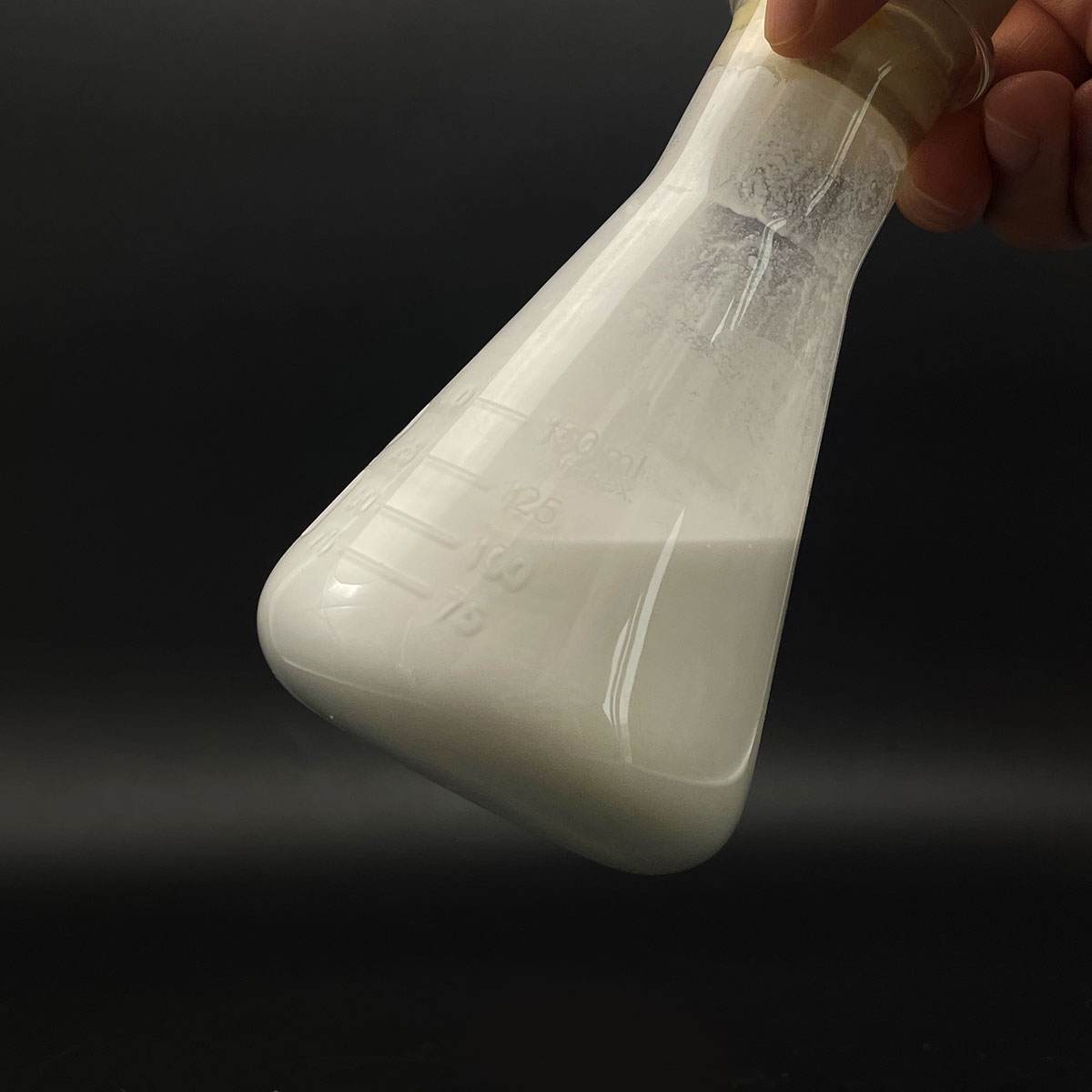

Niobium, also known asNb, is a chemical element with the atomic number 41 and belongs to the transition metal group in the periodic table. It is a silvery-gray, lustrous metal that exhibits unique properties, making it an essential material in various high-tech applications.

High purity niobium ingots, which are the subject of this discussion, are produced through a rigorous refining process. These ingots consist of nearly 99.99% pure niobium, ensuring exceptional purity and minimizing impurities that could affect their performance. The manufacturing process typically begins with mining of niobium-rich ores, such as columbite or tantalite, followed by beneficiation, smelting, and electrolytic refining.

The ingots are formed by casting molten niobium into a mold, where it solidifies into a dense, cylindrical shape. The ingot size can vary, but they are often standardized to facilitate further processing and meet industry requirements. The dimensions of these ingots, including length, diameter, and weight, are carefully controlled to ensure consistency and compatibility with different fabrication techniques.

One of the key characteristics of high purity niobium is its superconducting properties. When cooled below a critical temperature (approximately 9.2 K for pure niobium), it exhibits zero electrical resistance, making it ideal for applications in magnetic resonance imaging (MRI) machines, particle accelerators, and energy-efficient power transmission lines. The ingots serve as the raw material for fabricating superconducting wires, tapes, and other components.

Niobium is also utilized in the aerospace industry due to its lightweight nature and excellent mechanical strength. It is used in the construction of aircraft engines, as well as in the manufacture of rocket nozzles and satellite components, where its corrosion resistance and high thermal conductivity are advantageous.

In nuclear reactors, niobium is employed in the construction of control rods and heat exchangers, thanks to its strong neutron absorbtion capacity and ability to maintain structural integrity under extreme conditions. Additionally, it finds applications in the production of capacitors, particularly in radio frequency (RF) devices, where its dielectric properties and low surface resistance are crucial.

In the field of electronics, niobium is employed in the fabrication of microwave components, such as resonators and cavities, due to its high electron mobility and low loss tangent. This enables efficient transmission and manipulation of electromagnetic signals.

In summary, high purity niobium ingots are a cornerstone of modern technology, offering unique properties that make them indispensable in numerous industries. Their purity ensures optimal performance in applications ranging from superconductivity to aerospace engineering, nuclear energy, and electronic devices. As research and innovation continue to advance, niobium’s versatility and potential will likely drive further exploration and development in the years to come.

(Niobium block pure Niobium metal High purity Niobium ingot)

FAQs of Niobium block pure Niobium metal High purity Niobium ingot

Inquiry us