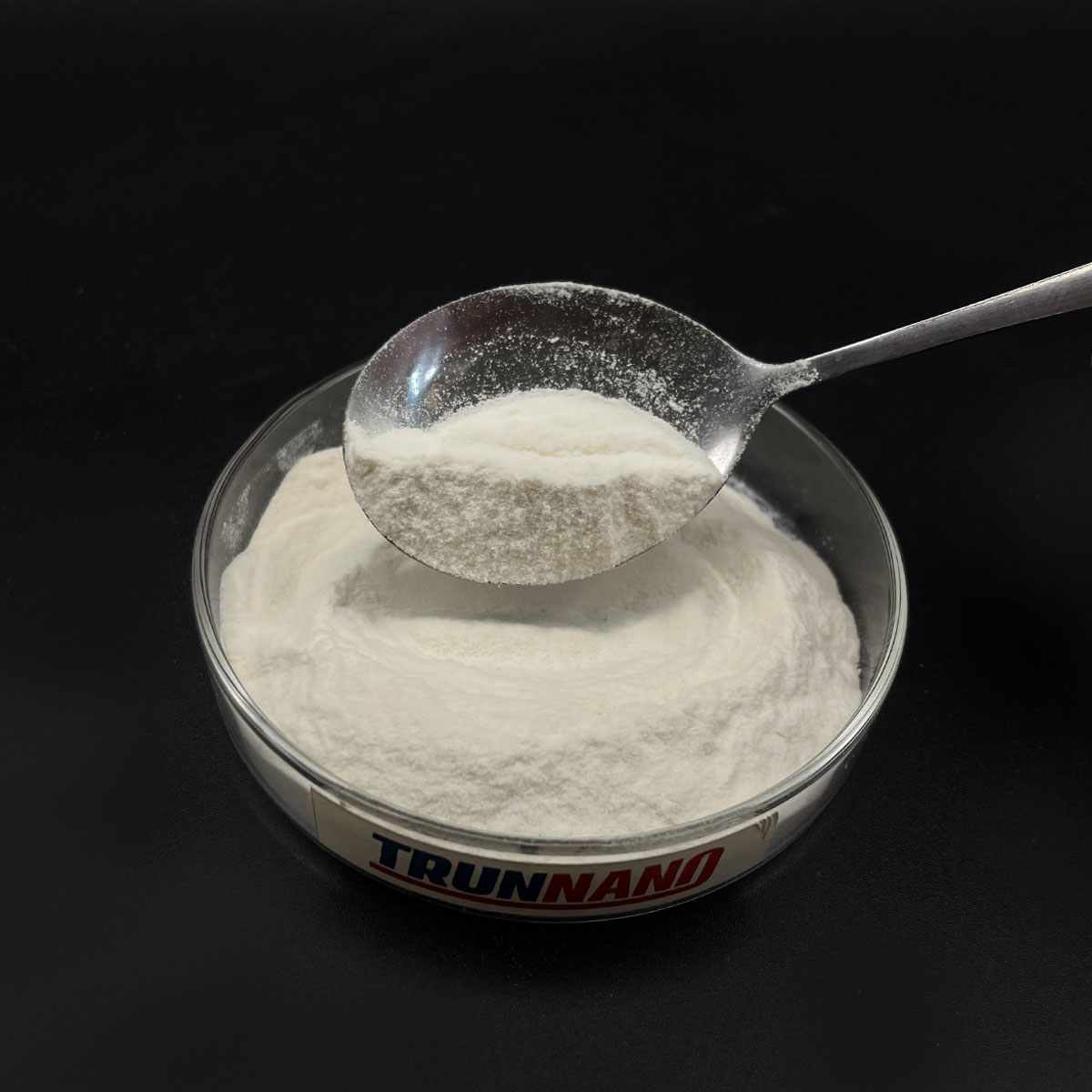

Overview of Mutiple Carbide Solution powder 50Ta50Nb 50/50 Tantalum Carbide/Niobium Carbide

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Mutiple Carbide Solution powder 50Ta50Nb 50/50 Tantalum Carbide/Niobium Carbide

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Mutiple Carbide Solution powder 50Ta50Nb 50/50 Tantalum Carbide/Niobium Carbide)

Parameters of Mutiple Carbide Solution powder 50Ta50Nb 50/50 Tantalum Carbide/Niobium Carbide

Multiple Carbide Solution (MCS) powders, specifically 50Ta50Nb, are a high-performance composite material composed of a blend of tantalum carbide (TaC) and niobium carbide (NbC). These powders have gained significant attention in various industrial applications due to their unique properties, which make them ideal for extreme conditions.

Tantalum carbide, with its exceptional hardness and wear resistance, is known for its ability to maintain its integrity under high temperatures and mechanical stress. It exhibits excellent chemical stability, making it resistant to corrosion and erosion, which are crucial factors in applications such as aerospace, automotive, and chemical processing industries. TaC also possesses high thermal conductivity, contributing to its use in heat sinks and electrical contacts.

Niobium carbide, on the other hand, boasts a high melting point and low density, which makes it lightweight yet strong. This combination of strength and low weight is particularly advantageous in the field of lightweight components for aerospace and automotive industries. NbC also displays good electrical resistivity, making it suitable for electronic applications like semiconductor manufacturing.

The 50Ta50Nb MCS powder blend offers a synergistic effect, where the complementary properties of both tantalum and niobium carbides are combined. The mixture enhances the overall hardness, toughness, and wear resistance of the material, while maintaining its desirable thermal and electrical characteristics. This balanced composition allows for improved performance in applications that require a combination of strength, durability, and resistance to harsh environments.

The manufacturing process of this powder involves a proprietary multiple carbide solution technique, which ensures a uniform distribution of the two carbides within the matrix. This results in a homogeneous microstructure, leading to consistent performance across different parts and minimizing potential weaknesses. The particle size and morphology of the powder can be tailored to meet specific requirements, enabling better control over the final product’s properties.

In terms of processing, the 50Ta50Nb MCS powder is suitable for various fabrication methods, including sintering, hot pressing, and additive manufacturing techniques. Its versatility makes it applicable to a wide range of applications, from cutting tools, bearings, and gears to wear-resistant coatings and even as a component in ceramic matrix composites.

In summary, the 50Ta50Nb Multiple Carbide Solution powder is a technologically advanced material that combines the best attributes of tantalum and niobium carbides. Its unique properties make it an attractive choice for demanding applications, offering improved performance, durability, and resistance to extreme conditions. As the demand for innovative materials continues to grow, this composite powder is poised to play a vital role in the future of engineering and manufacturing.

(Mutiple Carbide Solution powder 50Ta50Nb 50/50 Tantalum Carbide/Niobium Carbide)

FAQs of Mutiple Carbide Solution powder 50Ta50Nb 50/50 Tantalum Carbide/Niobium Carbide

Inquiry us