Overview of Molybdenum trioxide/Molybdenum(VI) oxide cas 1313-27-5

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Molybdenum trioxide/Molybdenum(VI) oxide cas 1313-27-5

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Molybdenum trioxide/Molybdenum(VI) oxide cas 1313-27-5)

Parameters of Molybdenum trioxide/Molybdenum(VI) oxide cas 1313-27-5

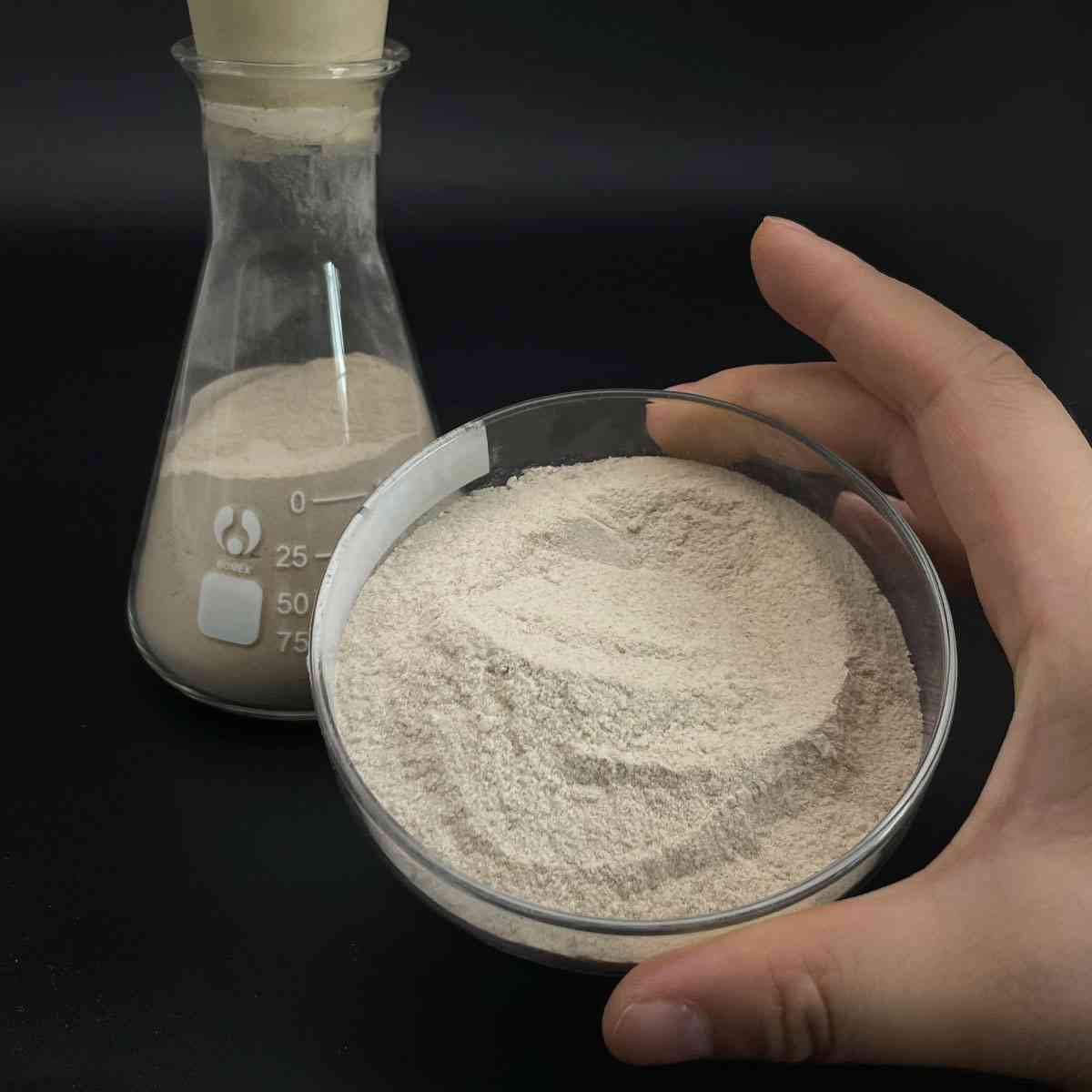

Molybdenum trioxide, also known as Molybdenum(VI) oxide or MoO3, is an inorganic compound with the chemical formula MoO3. It is a key compound derived from the element molybdenum, which is a transition metal found on the periodic table, group 6, period 5. Molybdenum is renowned for its exceptional properties, particularly in high-temperature and corrosion-resistant applications.

At room temperature, molybdenum trioxide exists as a white or yellowish-white solid, crystalline in nature, and has a hexagonal structure. It is a non-flammable and non-toxic compound, although prolonged exposure to fine particles can cause respiratory issues due to its potential to irritate the lungs. The compound is highly stable, resistant to acids and alkalis, making it useful in various industrial processes where chemical stability is crucial.

Molybdenum trioxide is widely used in several industries due to its unique properties. One of its most significant applications is in the production of high-performance ceramics, such as molybdenum carbides and nitrides, which are used in cutting tools, wear-resistant coatings, and thermal insulation materials. Its hardness and resistance to heat make it ideal for these demanding applications.

In the chemical industry, molybdenum trioxide serves as a catalyst in various reactions, including the oxidation of hydrocarbons and the conversion of ammonia into nitric acid. Its ability to lower the activation energy of these reactions makes it a valuable component in the manufacturing of fertilizers and other chemicals.

Another important application of molybdenum trioxide is in the field of electronics, where it is used as a dopant to enhance the performance of semiconductors. By introducing molybdenum atoms into silicon or other semiconductor materials, the electrical conductivity can be improved, leading to the development of advanced electronic devices.

Environmental remediation is another area where molybdenum trioxide finds use. It acts as a sorbent, capable of absorbing heavy metals like mercury, lead, and arsenic from contaminated water or soil, making it a potential candidate for cleaning up pollution.

Molybdenum trioxide also plays a role in the production of pigments and dyes, providing a range of colors in various applications, from cosmetics to paint. Its lightfastness and color stability make it a popular choice for long-lasting and vibrant hues.

Despite its many uses, the synthesis of molybdenum trioxide can be challenging, involving complex chemical processes, often involving high temperatures and pressure. However, advancements in technology have led to more efficient methods, making it more accessible and affordable for various industries.

In conclusion, molybdenum trioxide, or MoO3, is a versatile compound with a myriad of applications due to its unique properties. From high-performance materials to catalysis, electronics, and environmental remediation, this oxide of molybdenum continues to play a vital role in modern technology and industry. As research and innovation continue, it is likely that new applications and discoveries will further expand the scope of molybdenum trioxide’s importance.

(Molybdenum trioxide/Molybdenum(VI) oxide cas 1313-27-5)

FAQs of Molybdenum trioxide/Molybdenum(VI) oxide cas 1313-27-5

Inquiry us