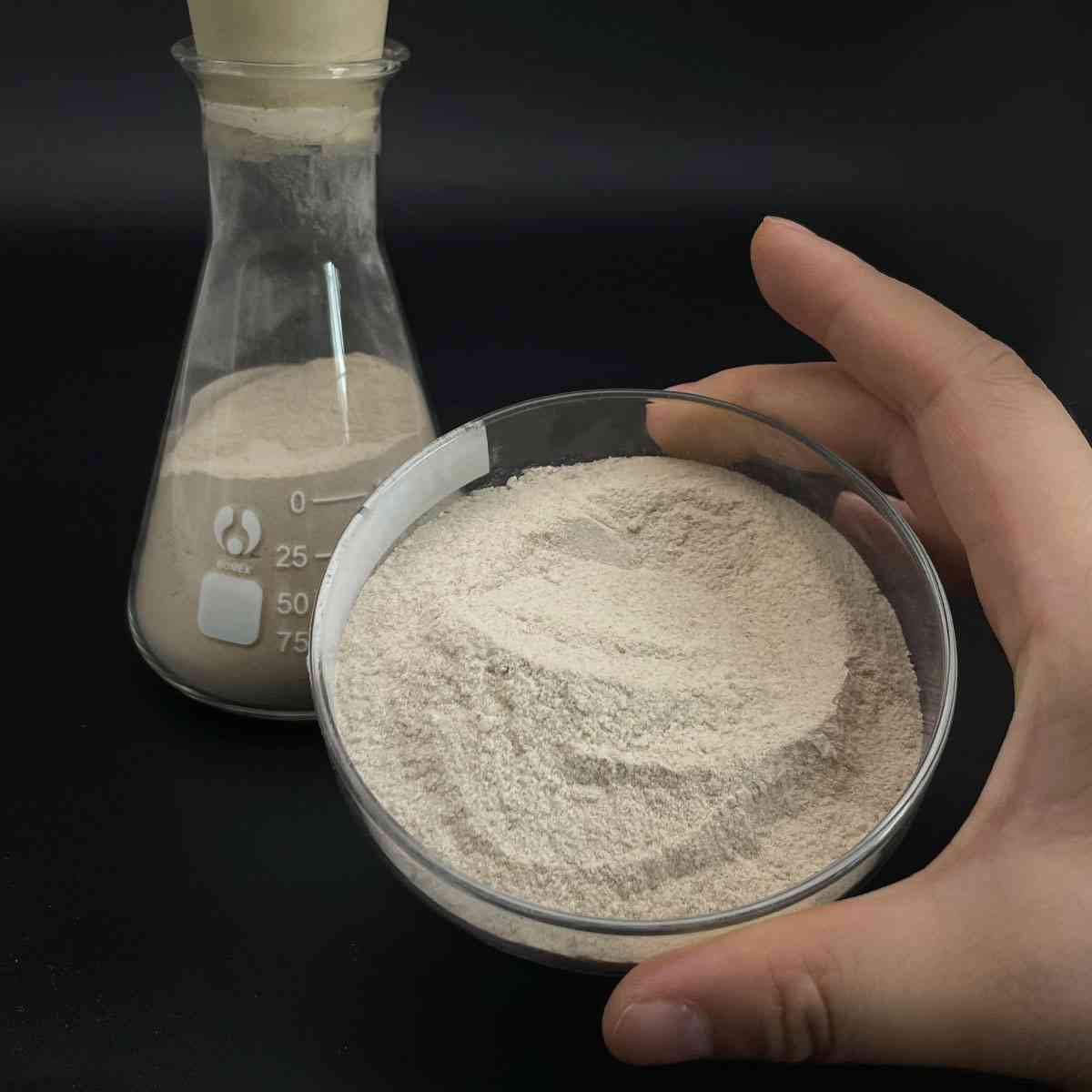

Overview of Mo 57% roasted molybdenum concentrates or industrial molybdenum oxide powders for ferrous molybdenum production

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Mo 57% roasted molybdenum concentrates or industrial molybdenum oxide powders for ferrous molybdenum production

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Mo 57% roasted molybdenum concentrates or industrial molybdenum oxide powders for ferrous molybdenum production)

Parameters of Mo 57% roasted molybdenum concentrates or industrial molybdenum oxide powders for ferrous molybdenum production

Molybdenum, a crucial element with the atomic number 42, plays a vital role in various industries due to its exceptional properties such as high strength, wear resistance, and corrosion resistance. It is primarily used to enhance the performance of steel and alloys, making them stronger and more durable. Ferrous molybdenum production involves the extraction and conversion of molybdenum into a form that can be incorporated into steel and other metal products.

The process begins with the mining of molybdenite, the most common ore containing molybdenum. This ore typically contains around 5-10% molybdenum, but Mo 57%, a roasted molybdenum concentrate, is often sought after for its higher concentration, which simplifies downstream processing. Roasting, a thermal treatment, involves heating the ore to drive off impurities and increase the molybdenum content. This step raises the molybdenum percentage to approximately 57%, making it more suitable for refining and further purification.

Once the concentrate is obtained, it undergoes a series of refining processes. These may include grinding the concentrate into a fine powder, followed by chemical leaching or hydrometallurgical methods to separate molybdenum from other minerals. The molybdenum oxide (MoO3) is then produced, which is a key intermediate product in ferrous molybdenum production.

Industrial molybdenum oxide powders are prepared through various techniques, such as calcination, which involves heating the oxide to remove moisture and improve its reactivity. The resulting powders have a high purity and are typically in the form of micron-sized particles, enabling efficient incorporation into steel during smelting.

The final step in ferrous molybdenum production is the reduction process, where the molybdenum oxide is reduced to molybdenum metal using reducing agents like hydrogen or carbon monoxide. This reaction occurs at high temperatures under controlled conditions to yield a high-purity molybdenum metal that is then alloyed with iron to create molybdenum steels.

The demand for molybdenum is driven by its applications in industries like aerospace, automotive, oil and gas, power generation, and construction, where materials with enhanced strength and corrosion resistance are essential. Molybdenum steels find use in components like jet engine parts, turbine blades, and pipelines, showcasing the importance of this strategic metal.

In conclusion, the production of ferrous molybdenum involves the extraction of molybdenite, concentrating it into Mo 57% roasted molybdenum, refining it into industrial molybdenum oxide powders, and finally converting it into a metallic form through reduction. This entire process is critical to ensuring the high-performance characteristics of materials in various sectors, highlighting the significance of molybdenum in modern industry.

(Mo 57% roasted molybdenum concentrates or industrial molybdenum oxide powders for ferrous molybdenum production)

FAQs of Mo 57% roasted molybdenum concentrates or industrial molybdenum oxide powders for ferrous molybdenum production

Inquiry us