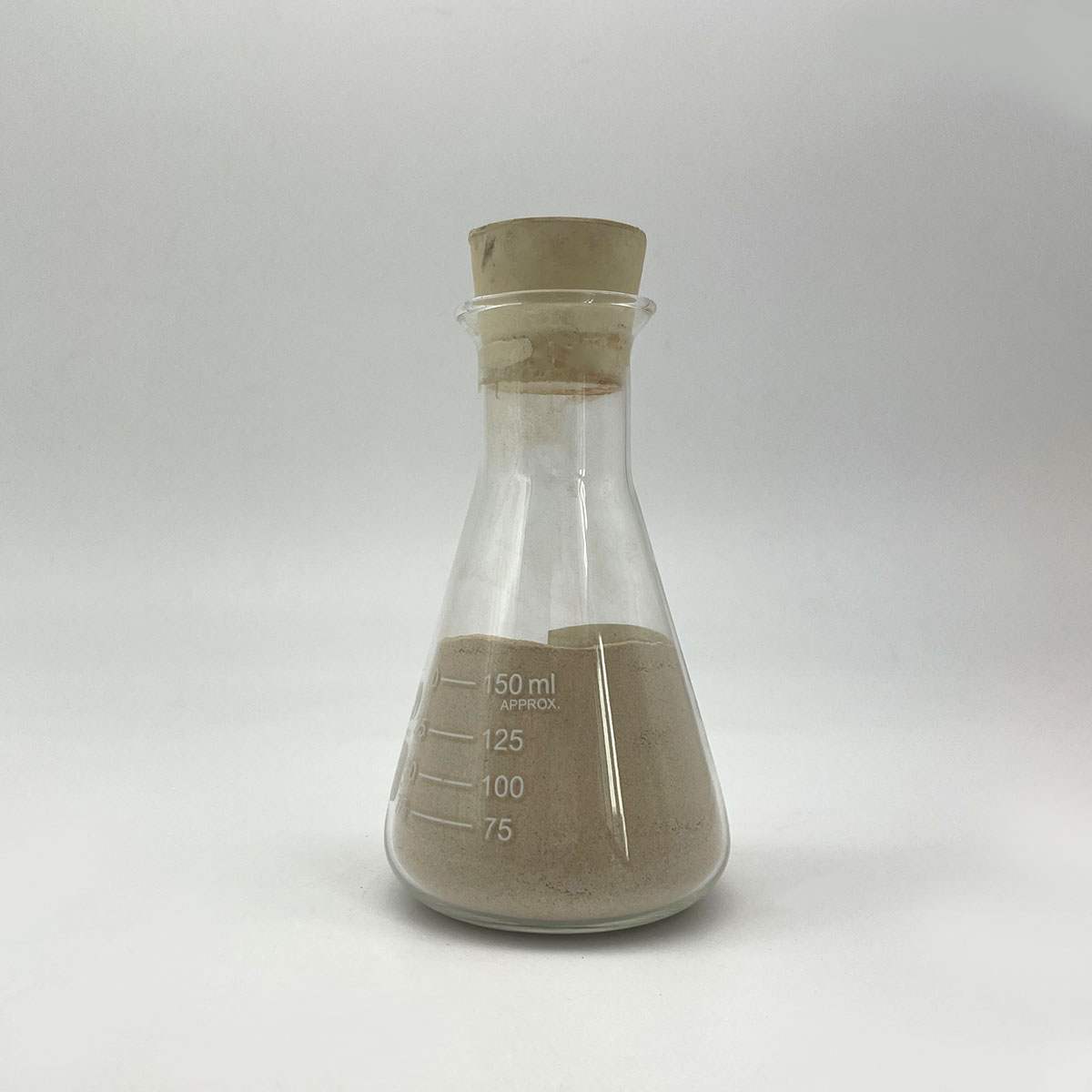

Overview of macrocrystalline tungsten carbide powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of macrocrystalline tungsten carbide powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(macrocrystalline tungsten carbide powder)

Parameters of macrocrystalline tungsten carbide powder

Macrocrystalline tungsten carbide powder is a high-performance material known for its exceptional strength, durability, and wear resistance. This particular form of tungsten carbide consists of large, well-defined crystal structures that significantly influence its mechanical properties and applications.

Tungsten carbide, with the chemical formula WC, is a compound of tungsten and carbon, where tungsten provides the metallic backbone and carbon acts as a hardening agent. The macrocrystalline variety, also referred to as polycrystalline or coarse-grained tungsten carbide, stands in contrast to fine-grained or microcrystalline forms, which have smaller grain sizes.

One of the key characteristics of macrocrystalline tungsten carbide powder is its large grain size, typically ranging from several micrometers to a few tens of micrometers. This larger grain structure allows for better mechanical properties, such as higher fracture toughness and fatigue resistance. The grains are interconnected, creating a more stable structure that can withstand higher loads and resist deformation under stress.

The hardness of macrocrystalline tungsten carbide is exceptional, often rated as Vickers hardness of around 2,500-3,000 HV. This hardness makes it ideal for applications requiring extreme, like cutting tools, wear-resistant coatings, and even armor piercing penetrators. The large grains also contribute to improved thermal conductivity, reducing heat accumulation during high-speed operations.

In terms of machining, macrocrystalline tungsten carbide powder is easier to process compared to its microcrystalline counterpart due to its lower brittleness. It can be formed into various shapes and sizes through processes like pressing and sintering, followed by grinding, milling, or turning. This ease of fabrication makes it suitable for manufacturing components in industries like automotive, aerospace, and mining, where high-performance and wear resistance are critical.

However, macrocrystalline tungsten carbide may not offer the same level of surface finish as microcrystalline powders due to its coarser grain structure. Nevertheless, this trade-off is often acceptable in applications where surface quality is less critical, and superior mechanical strength is the primary concern.

In summary, macrocrystalline tungsten carbide powder is a versatile material characterized by its large grain size, high hardness, and excellent wear resistance. Its unique properties make it ideal for demanding applications, such as cutting tools and wear-resistant coatings, where its superior mechanical strength outweighs the potential limitations in surface finish. Despite being less common than its microcrystalline counterpart, macrocrystalline tungsten carbide continues to play a significant role in modern engineering and manufacturing due to its inherent strengths.

(macrocrystalline tungsten carbide powder)

FAQs of macrocrystalline tungsten carbide powder

Inquiry us