Overview of Low supply high purity 99.95% metal evaporation materials tantalum granules

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Low supply high purity 99.95% metal evaporation materials tantalum granules

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

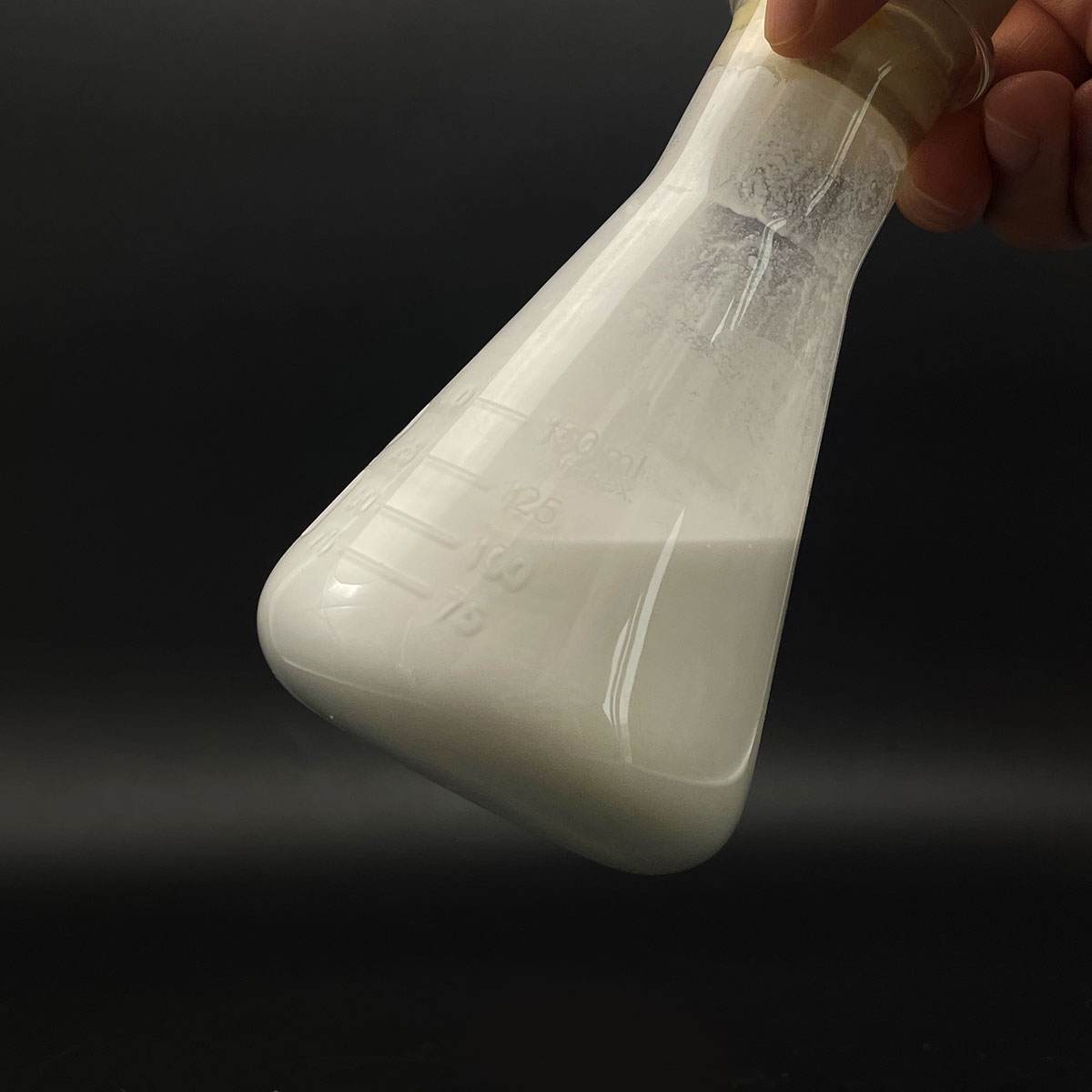

(Low supply high purity 99.95% metal evaporation materials tantalum granules)

Parameters of Low supply high purity 99.95% metal evaporation materials tantalum granules

Tantalum granules with a purity level of 99.95% are highly sought-after materials in various industries due to their exceptional properties. These granules, typically characterized by their low supply and high purity, exhibit remarkable features that make them indispensable in applications requiring extreme durability, stability, and conductivity.

Tantalum, a chemical element with the symbol Ta and atomic number 73, belongs to the niobium group in the periodic table. It is known for its robustness against corrosion, even in harsh environments, which makes it ideal for use in aerospace, nuclear, and semiconductor industries. The 99.95% purity grade ensures minimal impurities, enhancing its performance and reliability.

The granular form of tantalum offers several advantages. Firstly, the uniform size and shape of the particles facilitate handling and reduce the risk of contamination during processing. This is crucial in industries like electronics, where precision and cleanliness are paramount. Secondly, the granular structure allows for efficient transfer of heat and enables better surface area-to-volume ratios, promoting faster reaction rates in chemical processes.

In the tantalum industry, these granules are often used as raw materials for the fabrication of tantalum capacitors, which are essential components in electronic devices due to their high capacitance density and long-term stability. They also find application in the production of tantalum foils, which are used in high-temperature and high-pressure applications, such as fuel cells and chemical processing equipment.

Furthermore, tantalum’s high melting point (3017°C) and excellent thermal conductivity contribute to its use in heat exchangers, radiation shielding, and crucibles for high-temperature experiments. The 99.95% purity ensures that these applications benefit from minimal degradation over time.

Despite the demand for high-purity tantalum granules, their low supply reflects the challenges associated with extracting and refining this rare earth element. Tantalum is primarily mined from ore deposits found in countries like Congo, Rwanda, and Australia, which often involve complex environmental and social issues. As a result, the sourcing and refining process can be expensive and subject to strict regulations.

In conclusion, tantalum granules with a purity level of 99.95% are premium materials that offer exceptional performance and stability in demanding applications. Their unique properties, combined with the rarity of their supply, make them an invaluable resource in industries ranging from electronics to nuclear technology. However, the pursuit of these materials necessitates sustainable mining practices and responsible sourcing to ensure their continued availability for future technological advancements.

(Low supply high purity 99.95% metal evaporation materials tantalum granules)

FAQs of Low supply high purity 99.95% metal evaporation materials tantalum granules

Inquiry us