Overview of iridium tantalum anode mesh titanium electrolysis water titanium anode ruthenium oxide coated titanium cathode and anode plat

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of iridium tantalum anode mesh titanium electrolysis water titanium anode ruthenium oxide coated titanium cathode and anode plat

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(iridium tantalum anode mesh titanium electrolysis water titanium anode ruthenium oxide coated titanium cathode and anode plat)

Parameters of iridium tantalum anode mesh titanium electrolysis water titanium anode ruthenium oxide coated titanium cathode and anode plat

Iridium-Tantalum Anode Mesh in Titanium Electrolysis: A Comprehensive Overview

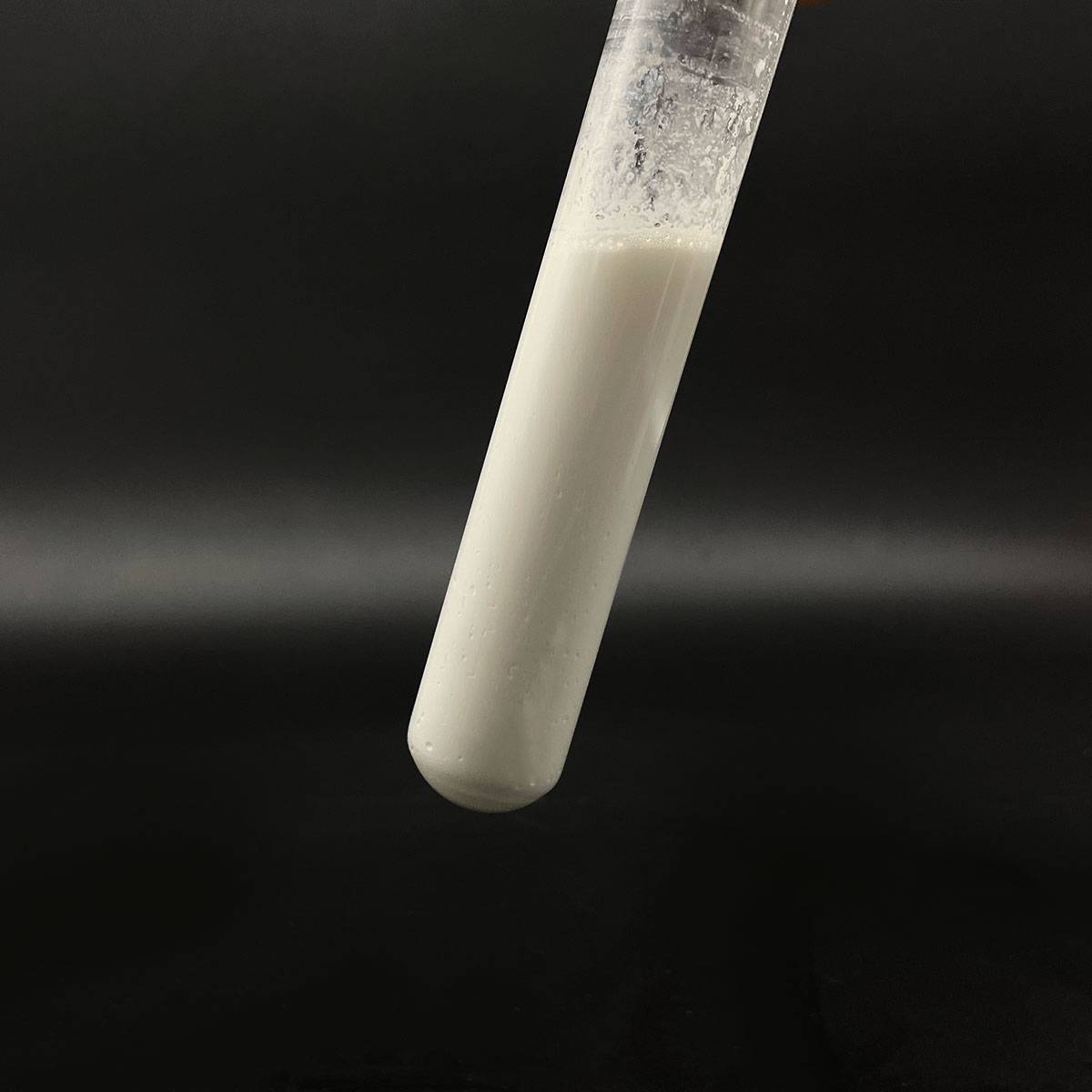

In the realm of advanced water purification and industrial processes, titanium-based electrolysis systems have garnered significant attention due to their durability, efficiency, and corrosion resistance. One critical component of such systems is the anode, where the chemical reactions take place, and in this context, iridium-tantalum anode meshes play a pivotal role.

Iridium-tantalum anodes are engineered with a combination of iridium and tantalum metals. Iridium, known for its exceptional chemical stability and high melting point, enhances the overall performance of the anode by providing excellent conductivity and minimizing the formation of scale or deposits. Tantalum, on the other hand, adds strength and resistance to wear, ensuring that the anode can withstand the harsh conditions encountered during electrolysis.

The mesh structure of the anode allows for a large surface area, facilitating efficient transfer of electrical energy to the water, promoting the desired chemical reactions. The mesh design also enables the easy passage of ions, preventing the buildup of concentrated impurities and enhancing the overall efficiency of the process.

The choice of titanium as the base material for the anode further bolsters its performance. Titanium is lightweight, strong, and chemically inert, making it resistant to corrosion even in aggressive environments. It has a low thermal expansion coefficient, which minimizes stress on the anode during temperature fluctuations, ensuring long-term reliability.

When it comes to the cathode, a titanium anode with a ruthenium oxide coating is often employed. Ruthenium oxide, known for its high catalytic activity, improves the electrochemical reaction rate and reduces the need for frequent maintenance. The coating also protects the underlying titanium from corrosion, extending its lifespan.

The anode plate, a crucial part of the setup, serves as the interface between the anode mesh and the electrolyte. It is typically made of pure titanium to maintain the system’s integrity and ensure optimal performance. The plate is designed to distribute the electrical current evenly across the mesh, minimizing hotspots and promoting uniform electrolysis.

In summary, the iridium-tantalum anode mesh, combined with a titanium substrate and a ruthenium oxide-coated titanium cathode, forms a robust and efficient electrolysis setup. The use of these materials and components results in a system that can effectively purify water or drive chemical reactions while maintaining minimal degradation over time. Their unique properties and design make them indispensable in various industries, including water treatment, metal refining, and chemical synthesis.

(iridium tantalum anode mesh titanium electrolysis water titanium anode ruthenium oxide coated titanium cathode and anode plat)

FAQs of iridium tantalum anode mesh titanium electrolysis water titanium anode ruthenium oxide coated titanium cathode and anode plat

Inquiry us