Overview of indoor outdoor 200g titanium powder composite ti cold powder for 650w 600w cold spark machine

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of indoor outdoor 200g titanium powder composite ti cold powder for 650w 600w cold spark machine

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

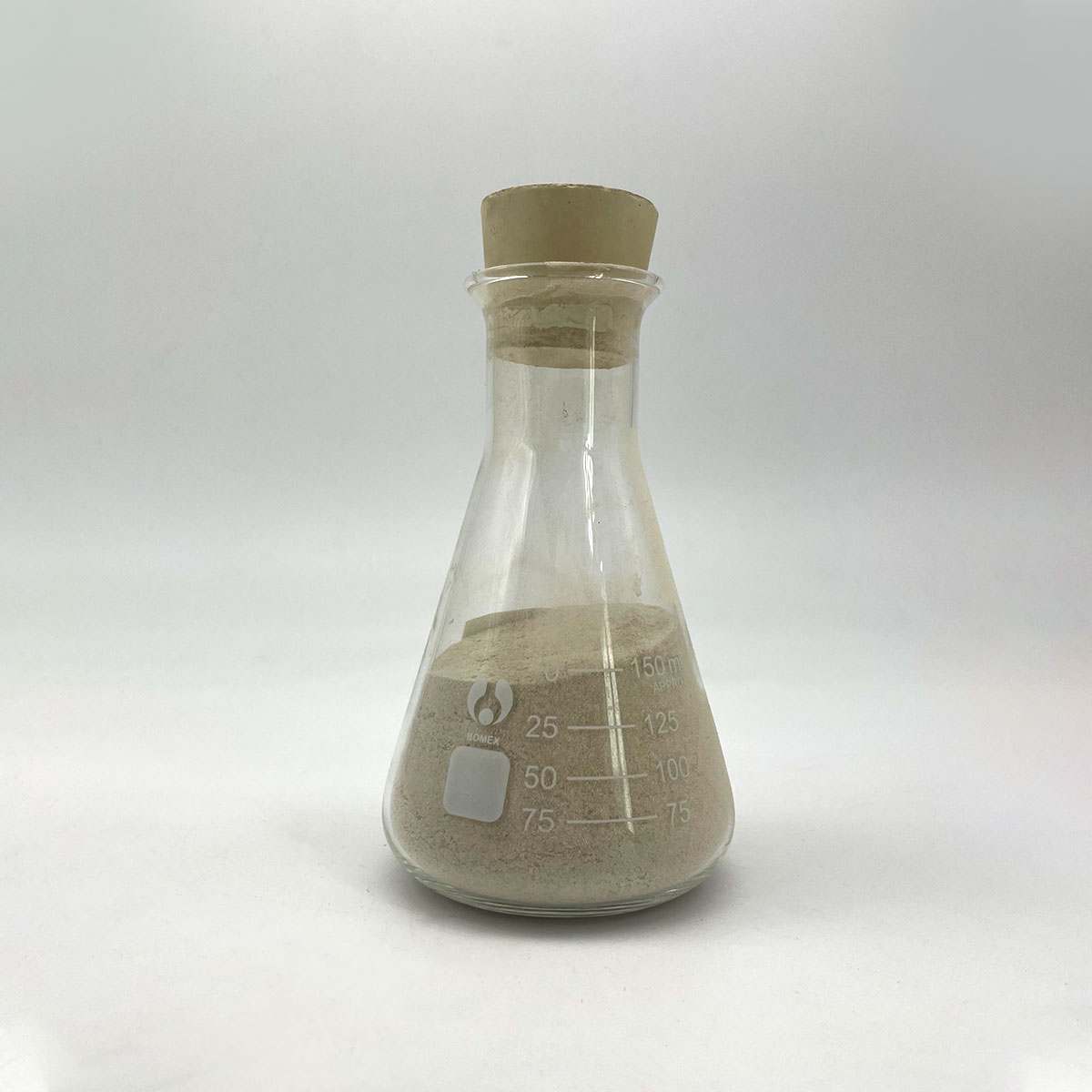

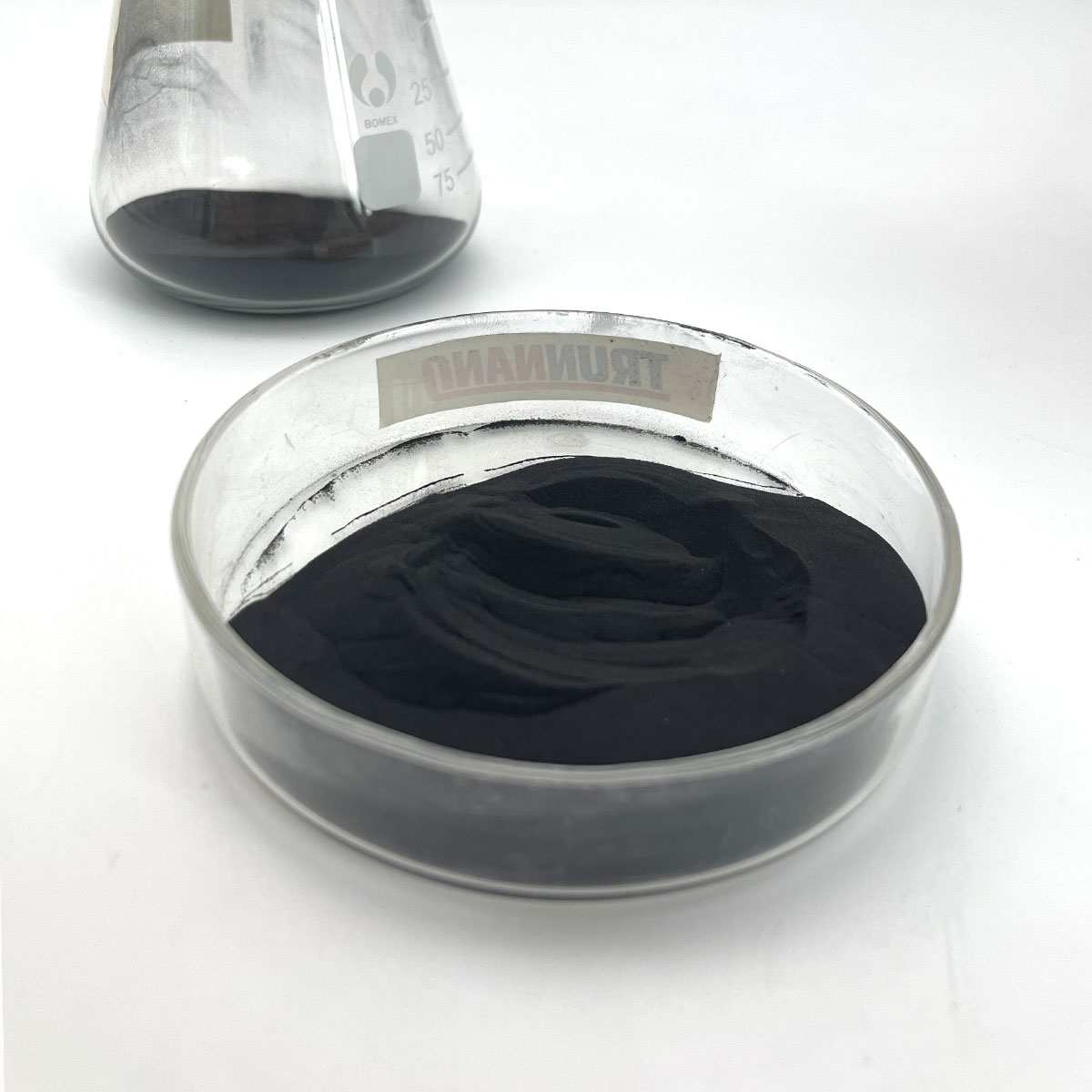

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(indoor outdoor 200g titanium powder composite ti cold powder for 650w 600w cold spark machine)

Parameters of indoor outdoor 200g titanium powder composite ti cold powder for 650w 600w cold spark machine

Title: Indoor-Outdoor 200g Titanium Powder Composite for Cold Spark Machines (650W & 600W): A Comprehensive Overview

Introduction:

The advent of high-performance, versatile materials in the world of cold spark machines has revolutionized the industry. Among these materials, titanium powders, particularly the 200g indoor-outdoor composite variety, have emerged as a game-changer for devices like 650W and 600W cold spark machines. This article delves into the key specifications, advantages, and applications of this innovative titanium compound.

Composition:

The 200g titanium powder composite is a blend of pure titanium particles, typically around 99.9% titanium content, with a carefully selected matrix material. The composite process involves combining titanium with other elements, such as carbon or boron carbide, to enhance its mechanical properties and resistance to wear and corrosion. This results in a lightweight yet strong material that withstands the rigors of both indoor and outdoor environments.

Performance Parameters:

1. Particle Size: The titanium powder used in this composite has a particle size distribution that ensures efficient mixing and bonding within the machine’s components. This uniformity contributes to a consistent output and optimal performance across different power settings.

2. Density: At 200g per volume, the titanium composite boasts an impressive density, which translates to durability without compromising portability. This makes it suitable for both fixed installations and portable cold spark machines.

3. Thermal Conductivity: With high thermal conductivity, the titanium composite allows for efficient heat dissipation, preventing overheating and extending the life of the machine.

4. Electrical Conductivity: Titanium’s inherent electrical conductivity enables smooth current flow, facilitating the generation of sparks with precision and reliability.

5. Power Compatibility: The 200g titanium powder composite is specifically designed for 650W and 600W cold spark machines, ensuring compatibility and optimized performance within these power ranges.

Applications:

1. Industrial Applications: In industries like metalworking, welding, and cutting, the titanium composite provides a reliable source of cold sparks for precise and clean processes, reducing the need for high-temperature tools.

2. Outdoor Events: Due to its weather-resistant nature, this composite is ideal for use in outdoor events, where exposure to moisture and varying temperatures is common. It maintains performance even in challenging conditions.

3. Scientific Research: Cold spark technology finds applications in scientific research, including plasma physics and atmospheric studies, where a stable and controllable spark source is essential.

4. Hobbyist Tools: The compact and durable nature of the 200g titanium powder composite makes it a popular choice for DIY enthusiasts who require a high-performance spark generator for hobbies like pyrotechnics and special effects.

Conclusion:

In summary, the 200g titanium powder composite for 650W and 600W cold spark machines represents a significant advancement in material technology. Its unique combination of strength, conductivity, and adaptability to diverse environments make it a sought-after component for various industrial, scientific, and recreational applications. As technology continues to evolve, the potential for further innovation in titanium-based composites will only expand the possibilities for cold spark machines.

(indoor outdoor 200g titanium powder composite ti cold powder for 650w 600w cold spark machine)

FAQs of indoor outdoor 200g titanium powder composite ti cold powder for 650w 600w cold spark machine

Inquiry us