Overview of Indium Ingot,Indium Metal

Telluride and selenide compounds play a significant role in the field of semiconductors, particularly in the development of advanced electronic and optoelectronic devices. These materials belong to the chalcogenide family, characterized by their ability to form compounds with elements from groups IV-VI in the periodic table.

Tellurides: Compounds containing tellurium (Te) as the chalcogen. Examples include cadmium telluride (CdTe), mercury telluride (HgTe), and zinc telluride (ZnTe). These materials have found applications in solar cells, infrared detectors, and high-speed electronics due to their tunable bandgap, high electron mobility, and good thermal stability.

Selenides: Similar to tellurides, but with selenium (Se) replacing tellurium. Notable examples are cadmium selenide (CdSe), gallium selenide (GaSe), and zinc selenide (ZnSe). Selenide compounds are widely used in light-emitting diodes (LEDs), laser diodes, and solar cells due to their direct bandgap properties and efficient light absorption/emission capabilities.

Feature of Indium Ingot,Indium Metal

Direct Bandgap: Many telluride and selenide semiconductors have direct bandgaps, which facilitate efficient light emission and absorption processes. This makes them suitable for optoelectronic applications such as LEDs and lasers.

Tunable Bandgap: The bandgap of these materials can be adjusted by alloying or altering the composition (e.g., CdSe to CdTe), enabling customization for specific device requirements across a wide spectrum of wavelengths.

High Electron Mobility: Materials like HgCdTe exhibit high electron mobility, which is crucial for high-speed electronic devices and low-noise detector applications.

Thermal Stability: Some tellurides and selenides, like ZnTe and ZnSe, demonstrate good thermal stability, making them suitable for high-temperature operation and processing.

Non-Toxic Alternatives: With increasing environmental concerns, there’s a push towards exploring less toxic alternatives to commonly used semiconductors. For instance, Cd-based tellurides and selenides are being replaced or combined with less toxic elements like Mg or Mn in some applications.

(Indium Ingot,Indium Metal )

Parameters of Indium Ingot,Indium Metal

Indium, a chemical element with the symbol In and atomic number 49, is a soft, silvery-white metal that belongs to the group 13 in the periodic table, alongside aluminum and gallium. It holds unique properties that make it a valuable material in various industries, particularly in electronics and semiconductors.

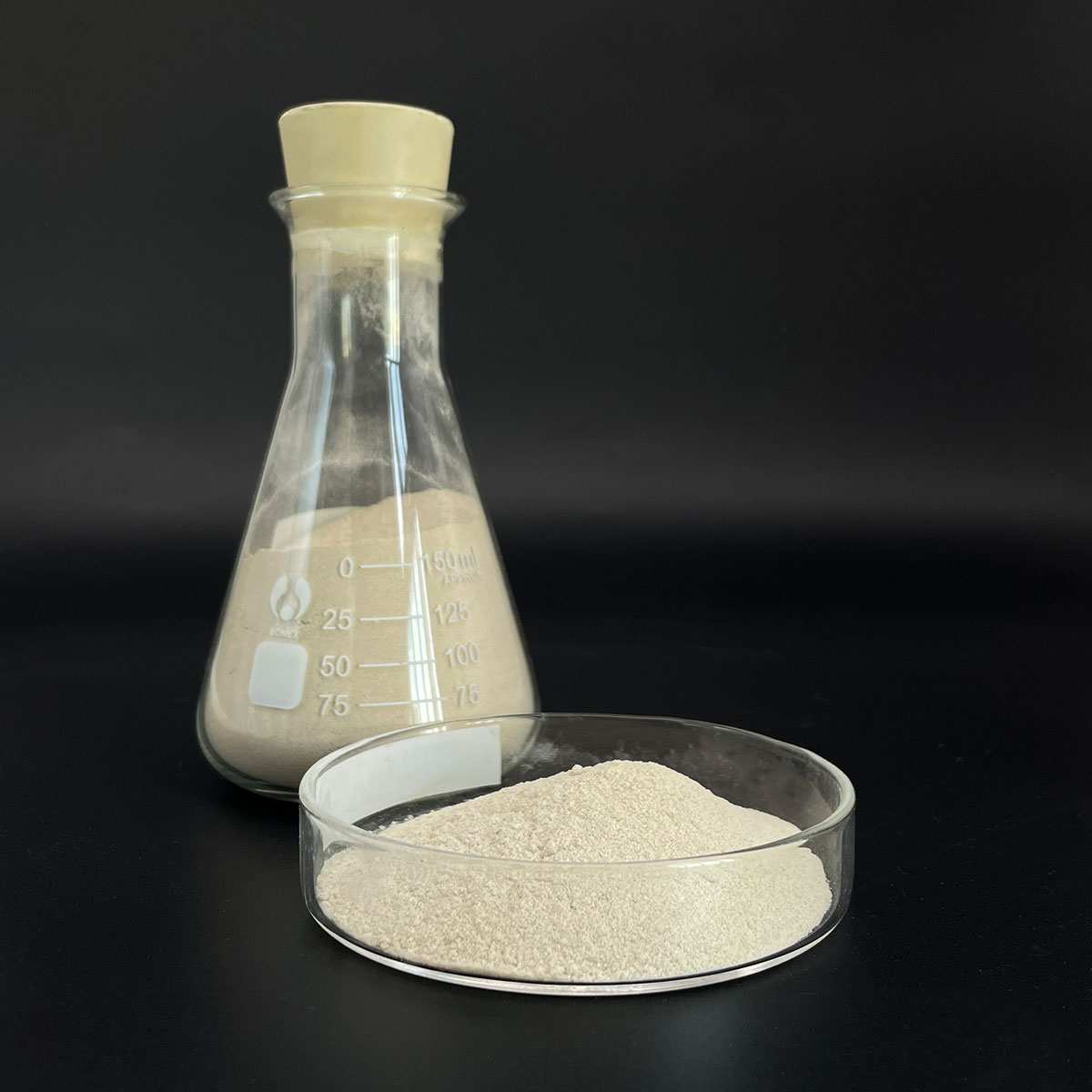

The raw material for indium production is primarily found in zinc ores, as indium is often a byproduct of zinc refining. The extraction process begins with mining zinc concentrates, which are then treated to separate indium from other metals. This typically involves roasting, leaching, and solvent extraction, followed by electrolysis to refine the indium metal.

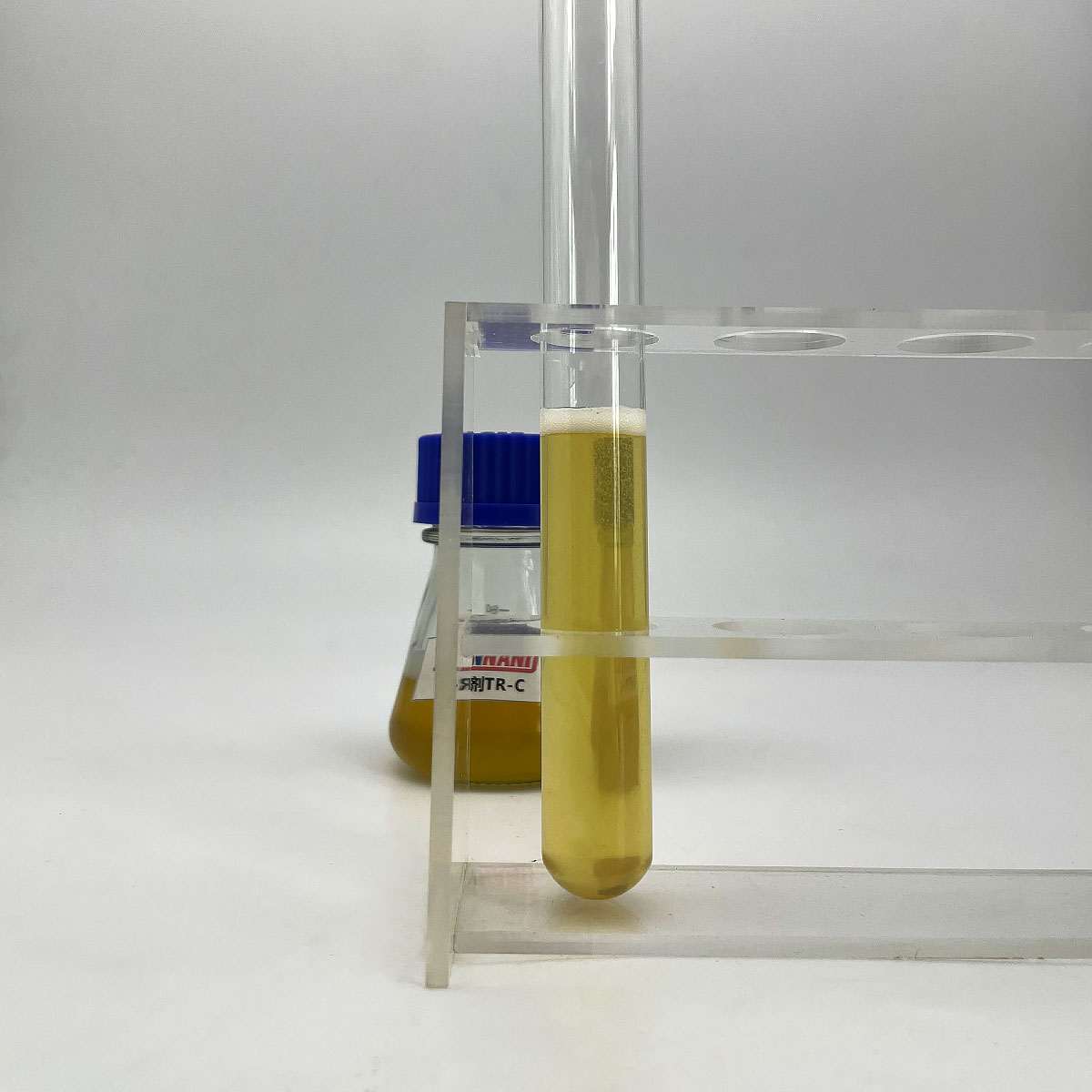

Indium ingot, the primary form in which it is sold, is a solid, cylindrical piece of pure indium that has been melted and cast into a desired shape. These ingots serve as the foundation for further processing into thin films, wires, and other components. The purity of indium ingots is crucial, as impurities can affect the performance and reliability of electronic devices.

One of the most distinctive features of indium is its high thermal and electrical conductivity. It has a relatively low melting point of 156.6°C (314°F), making it an ideal material for applications where heat dissipation is critical, such as in high-speed computer chips and solar cells. Indium’s ability to form a thin, flexible film also makes it indispensable in touchscreens, where it coats the glass substrate, providing excellent sensitivity and durability.

Indium tin oxide (ITO), a compound containing indium and tin, is another popular product derived from indium ingots. ITO is widely used in flat-panel displays, as it combines the conductive properties of indium with the optical clarity of tin dioxide. Its transparency and conductivity make it an essential component in LCD and OLED screens, as well as smart windows and energy-efficient lighting.

In the aerospace industry, indium’s lightweight and corrosion-resistant nature make it suitable for use in high-temperature applications, such as in the manufacturing of aircraft parts and satellite components. Additionally, indium alloys, like indium-tin and indium-copper, are employed in various industries due to their enhanced mechanical properties and resistance to wear and tear.

Despite its numerous benefits, indium is a rare element, with limited reserves. Its scarcity drives up the price, making it a costly but indispensable material in some high-tech sectors. As a result, recycling and efficient use of indium have become increasingly important to ensure a sustainable supply chain.

In conclusion, indium ingot, a versatile material with exceptional thermal and electrical conductivity, plays a vital role in modern technology. Its unique properties make it an integral part of electronic devices, displays, and aerospace applications. However, the challenges posed by its rarity emphasize the need for innovation in recycling and alternative sourcing methods to maintain its availability for future advancements.

(Indium Ingot,Indium Metal )

FAQ of Semiconductor Materials

Inquiry us