Overview of HSG Tantalum Powder Tantalum Carbide Powder Tantalum Carbide Powder Ta2C

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of HSG Tantalum Powder Tantalum Carbide Powder Tantalum Carbide Powder Ta2C

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(HSG Tantalum Powder Tantalum Carbide Powder Tantalum Carbide Powder Ta2C)

Parameters of HSG Tantalum Powder Tantalum Carbide Powder Tantalum Carbide Powder Ta2C

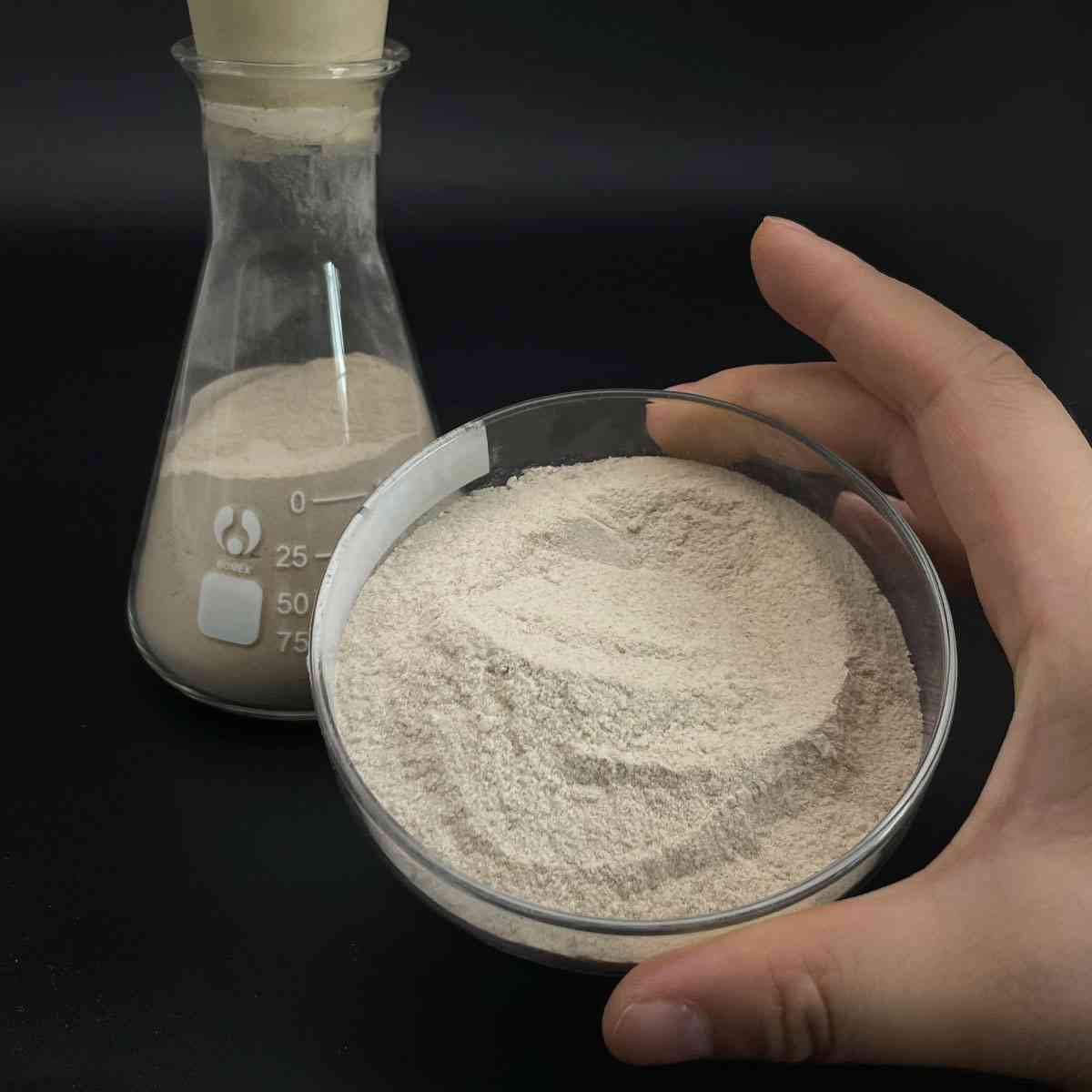

Tantalum powder, also known as tantalum carbide powder (Ta2C), is a high-performance material that finds extensive applications in various industries due to its unique combination of properties. Tantalum, a chemical element with the atomic number 73, belongs to the niobium group and exhibits exceptional strength, corrosion resistance, and heat stability. When combined with carbon, it forms tantalum carbide, which is an extremely hard and wear-resistant compound.

The primary characteristic of tantalum carbide powder is its microstructure, typically consisting of a metallic tantalum matrix intermixed with carbide particles. The Ta2C phase has a hexagonal crystal structure, providing excellent mechanical properties such as high hardness (up to 30 GPa) and high fracture toughness. This makes it suitable for applications where wear resistance is crucial, like cutting tools, brake pads, and coatings for bearings and gears.

One of the key features of tantalum carbide powder is its chemical inertness. It resists corrosion from acids, alkalis, and even molten salts, making it ideal for use in harsh environments. Its thermal stability also allows it to maintain its integrity under elevated temperatures, which is advantageous in aerospace, automotive, and electronics industries where temperature resistance is essential.

In terms of particle size distribution, tantalum carbide powder can be tailored to meet specific requirements. It is available in a range of grades, from submicron to micron-sized particles, enabling fine control over the surface area and reactivity. This versatility enables users to choose the most appropriate particle size for their application, whether it’s enhancing wear resistance or improving the coating adherence.

Processing techniques, such as ball milling or sintering, are employed to produce the desired powder properties. These processes ensure uniform particle size, high purity, and controlled morphology, resulting in consistent performance across different applications. Tantalum carbide powder can also be mixed with other materials, like tungsten carbide or cobalt, to form composite powders, further enhancing their mechanical and tribological properties.

In summary, tantalum carbide powder is a premium material exceptional hardness, chemical stability, and thermal resistance. Its versatile nature, along with the ability to tailor particle size and composition, makes it an indispensable component in various sectors, including machining, automotive, aerospace, and energy. As research and technology continue to advance, the potential applications for tantalum carbide powder are expected to expand, driving innovation in numerous industries.

(HSG Tantalum Powder Tantalum Carbide Powder Tantalum Carbide Powder Ta2C)

FAQs of HSG Tantalum Powder Tantalum Carbide Powder Tantalum Carbide Powder Ta2C

Inquiry us