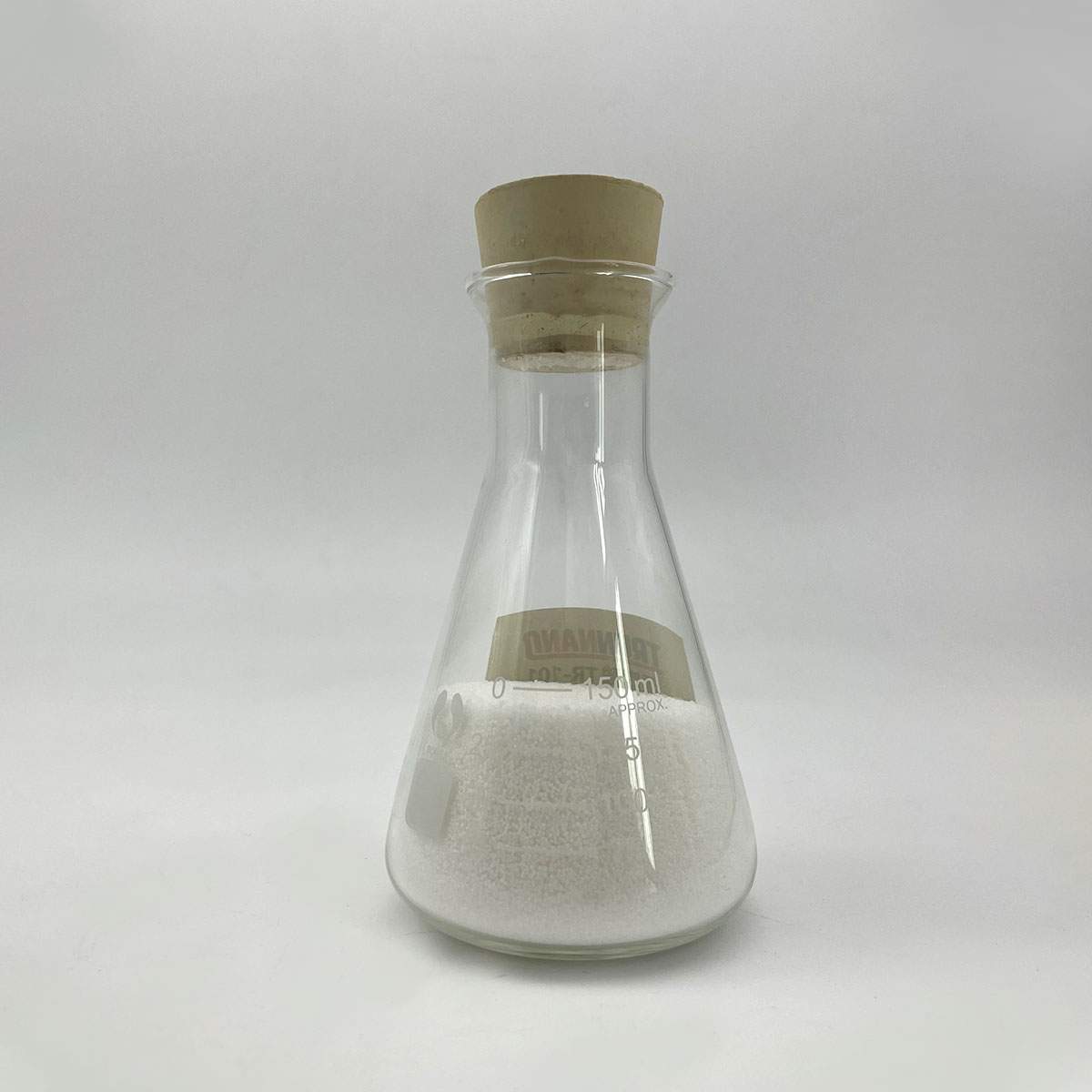

Overview of HRTA Metal TaC Ta2C Tantalous Tantalum Carbide Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of HRTA Metal TaC Ta2C Tantalous Tantalum Carbide Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(HRTA Metal TaC Ta2C Tantalous Tantalum Carbide Powder)

Parameters of HRTA Metal TaC Ta2C Tantalous Tantalum Carbide Powder

HRTA Metal, a leading manufacturer of advanced ceramic materials, specializes in producing tantalum carbides, including TaC, Ta2C, and tantalum carbide powders. These materials are renowned for their exceptional properties, making them indispensable in various industrial applications that require high-performance, durability, and resistance to extreme conditions.

Tantalum Carbide (TaC) is the first compound mentioned in this context. It is an intermetallic compound formed by the combination of tantalum (Ta) and carbon (C). TaC boasts a unique combination of strength, wear resistance, and thermal stability, which makes it ideal for applications such as cutting tools, wear-resistant coatings, and heat exchangers in aerospace, automotive, and energy industries. Its hardness rivals that of diamond, ensuring long service life and minimal tool wear.

Ta2C, or tantalum dicarbide, is another tantalum carbide derivative. This compound exhibits even higher hardness and wear resistance compared to TaC, making it suitable for demanding applications like components in heavy machinery, mining, and chemical processing. Its superior resistance to oxidation and corrosion also contributes to its longevity in harsh environments.

Tantalum Carbide Powders, available from HRTA Metal, are of utmost importance in powder metallurgy processes. These powders offer a versatile starting point for creating advanced tantalum carbide-based components through sintering or infiltration techniques. The particles possess a controlled particle size distribution, high purity, and excellent flowability, enabling precise control over the final product’s mechanical properties.

One key parameter in these powders is their grain size, which significantly affects the density, strength, and thermal conductivity of the final component. HRTA Metal focuses on optimizing grain size to achieve the desired balance between strength and processability, catering to specific customer requirements.

Another crucial factor is the purity level, which directly influences the performance of the tantalum carbide products. HRTA Metal ensures high purity levels, minimizing impurities that could compromise the material’s properties or introduce unwanted reactions during processing.

Furthermore, the particle shape and surface finish of the tantalum carbide powders are also essential. Well-shaped particles with smooth surfaces promote better bonding during consolidation and contribute to improved densification during sintering, resulting in fewer defects and enhanced mechanical properties.

In conclusion, HRTA Metal’s tantalum carbide powders, including TaC, Ta2C, and their derivatives, are characterized by exceptional properties like hardness, wear resistance, and thermal stability. By offering a range of parameters tailored to specific applications, HRTA Metal enables customers to unlock the full potential of these advanced materials in their respective industries. Their commitment to quality, customization, and innovation sets them apart in the market, making them a trusted partner for demanding engineering solutions.

(HRTA Metal TaC Ta2C Tantalous Tantalum Carbide Powder)

FAQs of HRTA Metal TaC Ta2C Tantalous Tantalum Carbide Powder

Inquiry us