Overview of Hot Niobium Oxide Nb2O5 Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Hot Niobium Oxide Nb2O5 Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

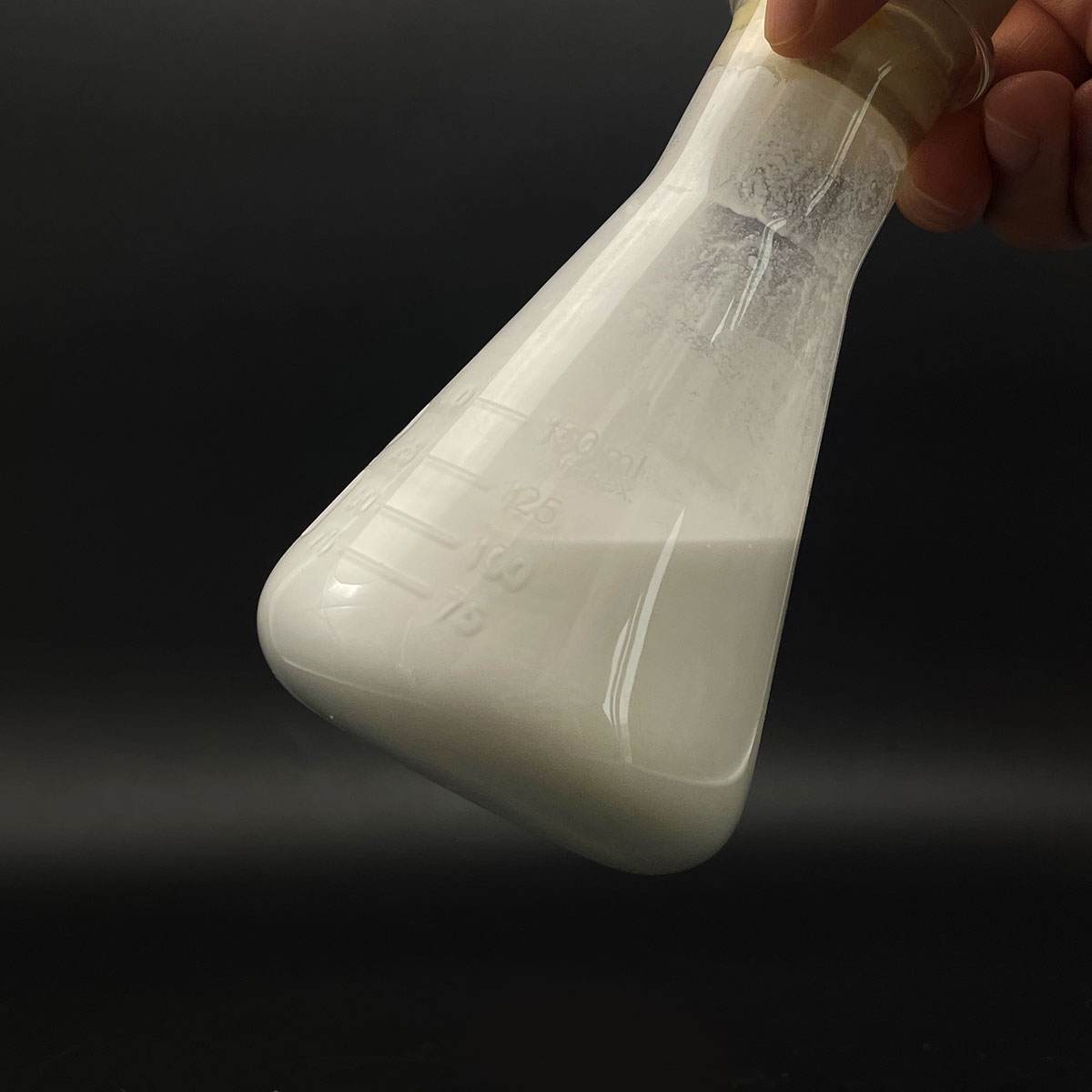

(Hot Niobium Oxide Nb2O5 Powder)

Parameters of Hot Niobium Oxide Nb2O5 Powder

Niobium oxide, also known as niobium pentoxide (Nb2O5), is a chemical compound that holds significant importance in various industrial applications due to its unique properties. It is an inorganic material formed by the combination of niobium and oxygen, with a chemical formula reflecting a 1:2 molar ratio between niobium and oxygen atoms. This compound is a versatile material that exhibits a wide range of thermal, electrical, and mechanical characteristics.

The hot niobium oxide powder, specifically, refers to the finely ground and thermally processed form of the compound. The particle size and morphology play a crucial role in determining its properties. The typical particle sizes for this powder can range from sub-micron to micron scales, allowing for high surface area and reactivity. The powder’s particle shape may be spherical, irregular, or agglomerated, depending on the manufacturing process.

One of the key features of hot niobium oxide is its high melting point, which stands at approximately 2,730°C (5,046°F). This exceptional thermal stability makes it suitable for applications where resistance to high temperatures is required, such as in ceramic coatings, refractories, and electronics components that operate in harsh environments.

The chemical inertness of niobium oxide makes it resistant to corrosion, making it ideal for use in chemical processing equipment, catalysts, and wear-resistant materials. Its ability to form strong bonds with other materials through oxidation also contributes to its utility in adhesive and bonding applications.

In terms of electrical conductivity, niobium pentoxide is an insulator at room temperature but becomes a conductor when subjected to high temperatures or under certain conditions. This property, known as a semiconductor-to-conductor transition, is exploited in electronic devices like varistors and thermistors.

The thermal conductivity of hot niobium oxide is relatively low compared to metals, but it has a high specific heat capacity, which helps in heat dissipation in applications like thermal management. Its dielectric constant is also relatively high, making it useful in capacitors and microwave components.

When it comes to purity, high-quality hot niobium oxide powders have a purity level of over 99%, ensuring minimal impurities that could affect performance. The synthesis methods, such as sol-gel, hydrothermal, or solid-state reactions, play a vital role in achieving this purity.

In summary, hot niobium oxide (Nb2O5) powder is a versatile material characterized by its high melting point, chemical inertness, and unique electrical properties. Its fine particle size and varied shapes make it adaptable for a wide range of applications, including electronics, ceramics, refractories, and even aerospace industries where thermal stability and resistance to corrosion are paramount. The purity and controlled synthesis techniques ensure consistent performance across different industries.

(Hot Niobium Oxide Nb2O5 Powder)

FAQs of Hot Niobium Oxide Nb2O5 Powder

Inquiry us