Overview of high quality ultrafine niobium powders for

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of high quality ultrafine niobium powders for

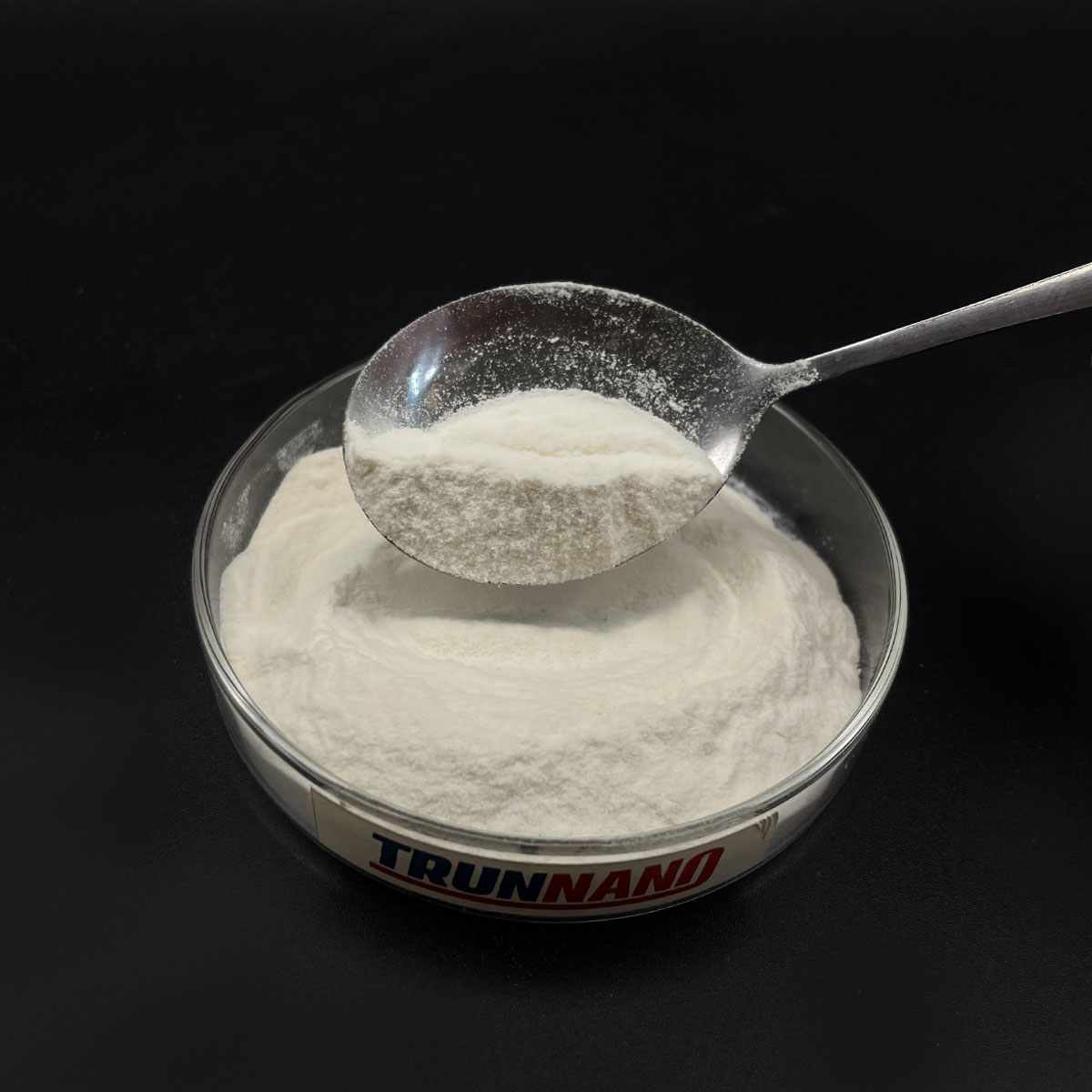

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(high quality ultrafine niobium powders for )

Parameters of high quality ultrafine niobium powders for

High-Quality Ultrafine Niobium Powders: A Comprehensive Overview

Niobium, with the chemical symbol Nb, is a metallic element that holds significant importance in various industrial applications due to its unique properties such as high strength, excellent corrosion resistance, and superconducting capabilities. Ultrafine niobium powders, characterized by their exceptionally small particle sizes and high purity, have become increasingly popular in recent years due to their wide range of uses across different sectors.

The manufacturing of ultrafine niobium powders begins with the extraction of niobium from its natural ores, typically found in Brazil, Canada, and Russia. These ores are processed through a series of refining steps, including smelting, electrolysis, and purification, to obtain a high-purity niobium metal. The subsequent powder production involves techniques like gas atomization, ball milling, or mechanical alloying, which help in reducing the metal into sub-micron particles.

One critical aspect of ultrafine niobium powders is their particle size distribution. These powders exhibit a narrow size range, typically ranging from 50 to 200 nanometers, which significantly influences their properties. The smaller particle size leads to a larger surface area, resulting in enhanced reactivity, improved sinterability, and better mechanical properties when formed into components.

In the field of superconductivity, ultrafine niobium powders play a pivotal role in the fabrication of high-temperature superconducting (HTS) materials. These powders are used in the preparation of conductive pastes and tapes that, when cooled below a certain critical temperature, exhibit zero electrical resistance. This property makes them ideal for applications in power transmission, magnetic resonance imaging (MRI), and advanced energy storage systems.

Another area where ultrafine niobium powders excel is in the aerospace industry. Their lightweight and strong nature make them suitable for use in the production of high-strength alloys for components such as engine parts, structural elements, and even satellite structures. These powders can be sintered to create dense, high-performance materials that withstand extreme temperatures and pressures.

Furthermore, in the electronics industry, niobium is employed in microwave and radio frequency devices due to its low loss tangent, which minimizes signal degradation. Ultrafine powders enable the creation of thin films and microelectronic devices with superior performance and efficiency.

Environmental stability is another crucial factor for high-quality ultrafine niobium powders. Purity levels above 99.99% ensure minimal contamination, making these powders suitable for applications where purity is paramount, such as in semiconductor fabrication processes.

In conclusion, high-quality ultrafine niobium powders are a versatile material with a multitude of applications due to their exceptional properties. Their small particle size, combined with high purity, enables them to offer enhanced performance in various industries, including superconductivity, aerospace, electronics, and more. As technology continues to advance, the demand for these powders is expected to grow, driving further innovation and development in the fields they support.

(high quality ultrafine niobium powders for )

FAQs of high quality ultrafine niobium powders for

Inquiry us