Overview of high quality pure molybdenum bar rod per kg

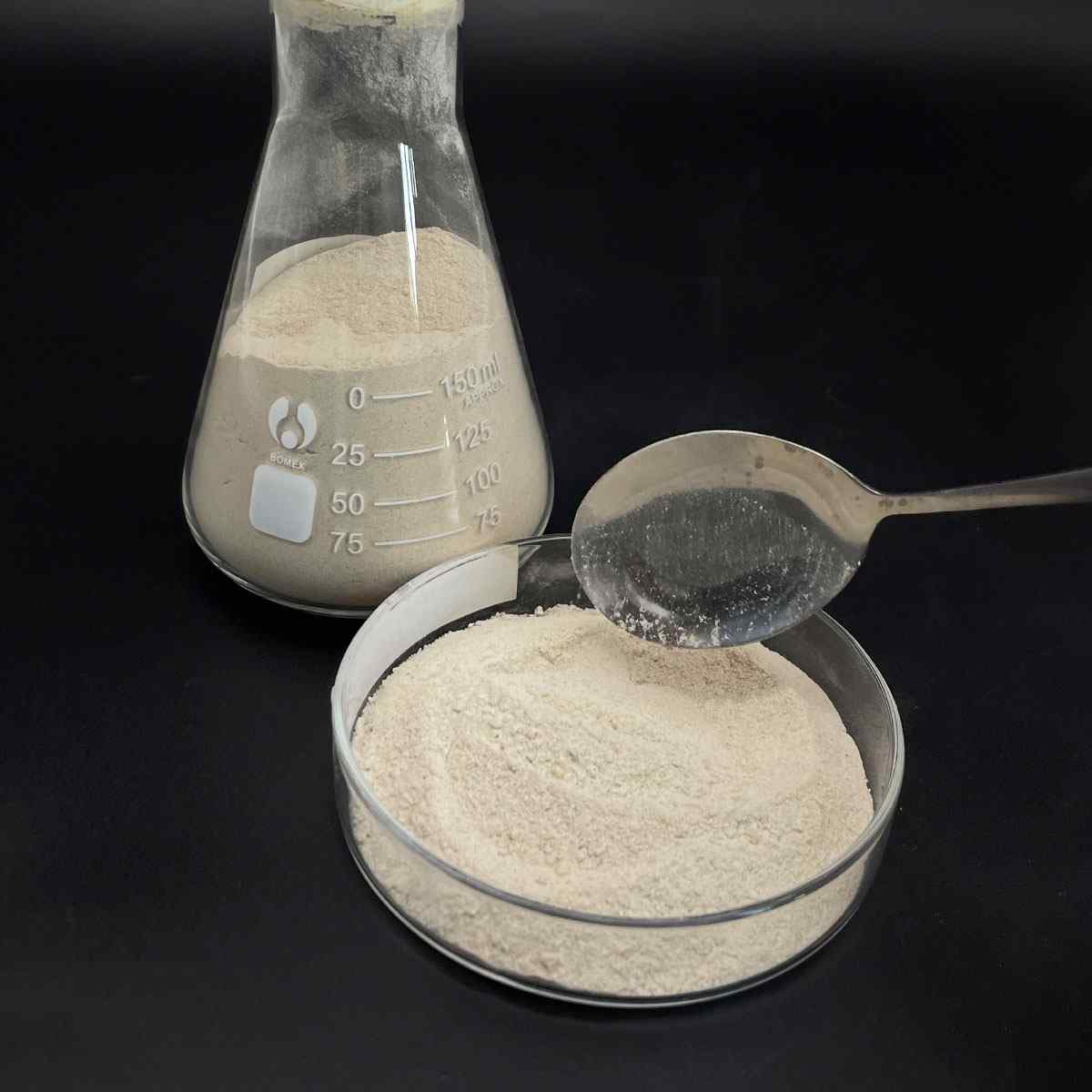

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of high quality pure molybdenum bar rod per kg

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(high quality pure molybdenum bar rod per kg)

Parameters of high quality pure molybdenum bar rod per kg

Molybdenum, a chemical element with the symbol Mo and atomic number 42, is a hard, dense, and corrosion-resistant metal that holds significant importance in various industries due to its unique properties. High-quality pure molybdenum bars and rods are sought-after for their exceptional strength, thermal stability, and resistance to high temperatures, making them ideal for demanding applications.

The purity of molybdenum bars and rods is a critical factor, typically measured as 99.9% or higher, ensuring minimal impurities and maximizing their performance. These bars are often produced through a refining process that starts with raw molybdenite ore, which undergoes smelting, electrolysis, and purification steps to isolate the pure metal. The refining process is rigorous to guarantee the desired purity level, which is essential for applications where material integrity and reliability are paramount.

Physical characteristics of high-quality molybdenum bars and rods include a metallic silver-gray luster, a high melting point of around 2,623°C (4,753°F), and excellent machinability. The density of molybdenum is approximately 10.22 g/cm³, giving it a solid, compact structure that can withstand immense pressure and stress without deformation. Its high thermal conductivity (about 118 W/m·K) makes it an efficient heat conductor, which is useful in applications like heat exchangers and thermocouples.

One of the key properties that set molybdenum apart is its exceptional resistance to oxidation and corrosion, even at elevated temperatures. This makes it ideal for use in harsh environments, such as aerospace, nuclear power, and chemical processing industries. Molybdenum’s ability to form a protective oxide layer upon exposure to air prevents further corrosion, extending the life of components.

High-quality molybdenum bars and rods are available in various shapes and sizes, including round, square, hexagonal, and custom profiles, to cater to different manufacturing requirements. They are commonly used in the production of turbine blades, bearings, electrical contacts, and structural components due to their strength-to-weight ratio and resistance to wear.

In addition to engineering applications, molybdenum is also employed in scientific research, where its high neutron absorption cross-section makes it suitable for use in nuclear reactors as control rods or shielding material. The element’s ability to enhance the performance of superalloys, particularly in high-temperature engines and gas turbines, further highlights its versatility.

In conclusion, high-quality pure molybdenum bars and rods offer a combination of strength, thermal stability, and corrosion resistance that make them indispensable in a wide range of industries. Their precise composition, combined with their machinability and adaptable shapes, ensure reliable performance in demanding applications, from aerospace to nuclear technology. As advancements continue to be made in material science, the importance of molybdenum in modern engineering will only continue to grow.

(high quality pure molybdenum bar rod per kg)

FAQs of high quality pure molybdenum bar rod per kg

Inquiry us