Overview of High purity 99.995% metal tantalum powder for 3D printing

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of High purity 99.995% metal tantalum powder for 3D printing

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

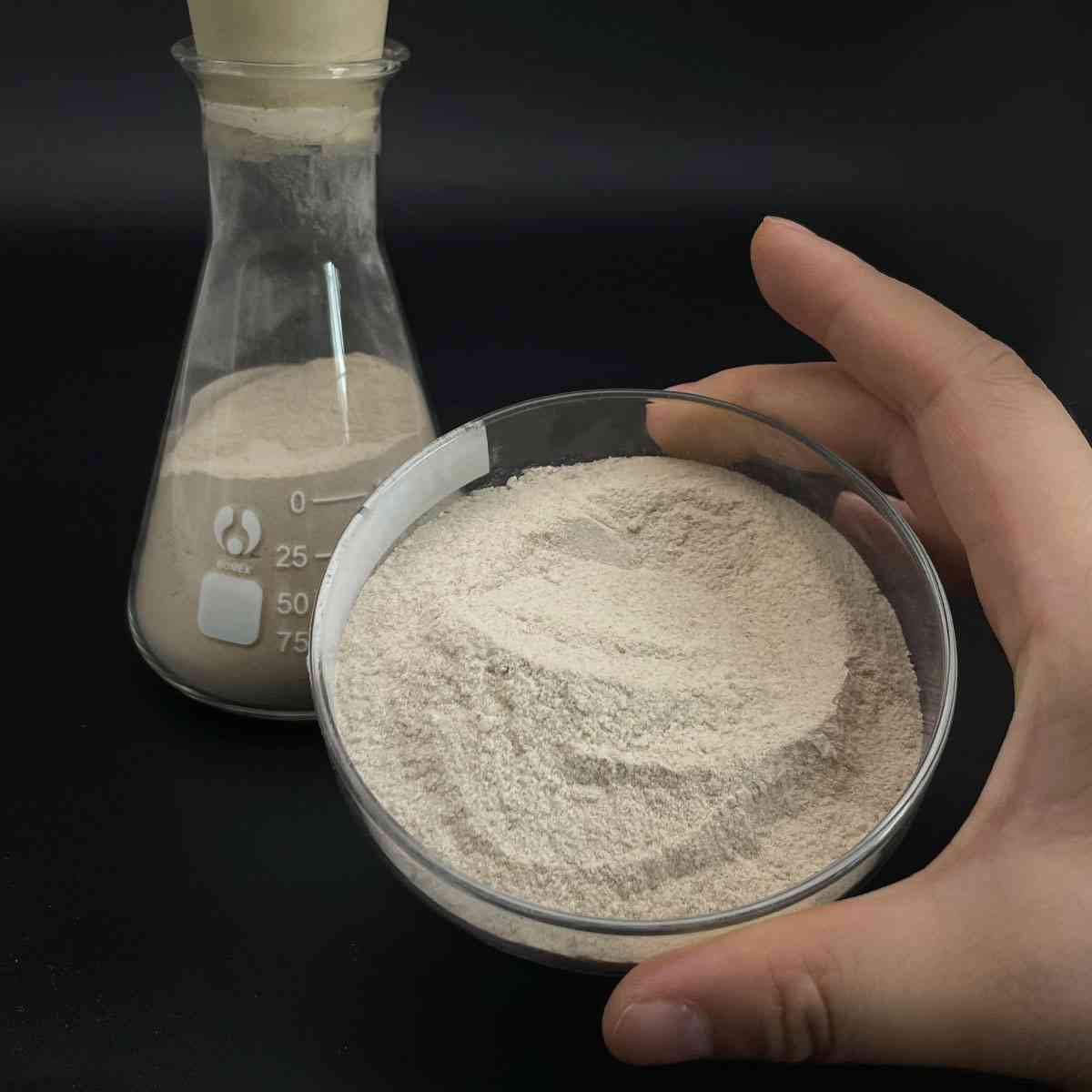

(High purity 99.995% metal tantalum powder for 3D printing)

Parameters of High purity 99.995% metal tantalum powder for 3D printing

High Purity Tantalum Powder for 3D Printing: A Revolutionary Material

Tantalum, with its atomic number 73 and chemical symbol Ta, is a rare and valuable transition metal known for its exceptional strength, corrosion resistance, and heat conductivity. It has emerged as a promising material in the realm of 3D printing due to its unique properties, particularly in applications requiring durability and precision.

The tantalum powder we offer boasts an unparalleled purity level of 99.995%, ensuring the highest quality for your 3D printing projects. This purity grade is crucial, as it minimizes impurities that could potentially affect print quality, dimensional stability, and the final mechanical properties of the printed parts.

In terms of particle size distribution, our tantalum powder is specifically formulated for optimal performance in 3D printing processes. It is engineered to have a narrow particle size range, typically between 10-60 microns, which enables better flowability, improved layer adhesion, and enhanced surface finish on the printed objects. This fine-grained structure allows for intricate designs and reduced build time.

One of the key benefits of using tantalum in 3D printing is its excellent thermal stability. Tantalum has a melting point of around 3,287°C (6,231°F), making it ideal for applications where high temperatures are involved, such as aerospace, medical implants, or extreme environment components. Its resistance to oxidation and corrosion ensures that the printed parts maintain their integrity over time.

Furthermore, tantalum’s high strength-to-weight ratio makes it suitable for lightweight yet robust components, which can be challenging to achieve with other materials. It can withstand immense mechanical stress and offers superior wear resistance, translating to longer-lasting products in demanding industries like automotive and defense.

Despite its inherent hardness, tantalum powder is compatible with various additive manufacturing techniques, including Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Directed Energy Deposition (DED). These processes allow for the creation of complex geometries and near-net-shape production, minimizing post-processing steps.

However, it is important to note that due to its rarity and cost, tantalum 3D printing may not be the most economically viable option for every project. It is often reserved for niche applications where performance and longevity are paramount. Nevertheless, the benefits it brings make it a game-changer in specific sectors where reliability and durability are non-negotiable.

In conclusion, our 99.995% pure tantalum powder is a cutting-edge material for 3D printing, offering a combination of strength, corrosion resistance, and thermal stability that sets it apart from conventional choices. As the technology advances, tantalum is poised to revolutionize the way we create components across industries, pushing the boundaries of what’s possible in additive manufacturing.

(High purity 99.995% metal tantalum powder for 3D printing)

FAQs of High purity 99.995% metal tantalum powder for 3D printing

Inquiry us