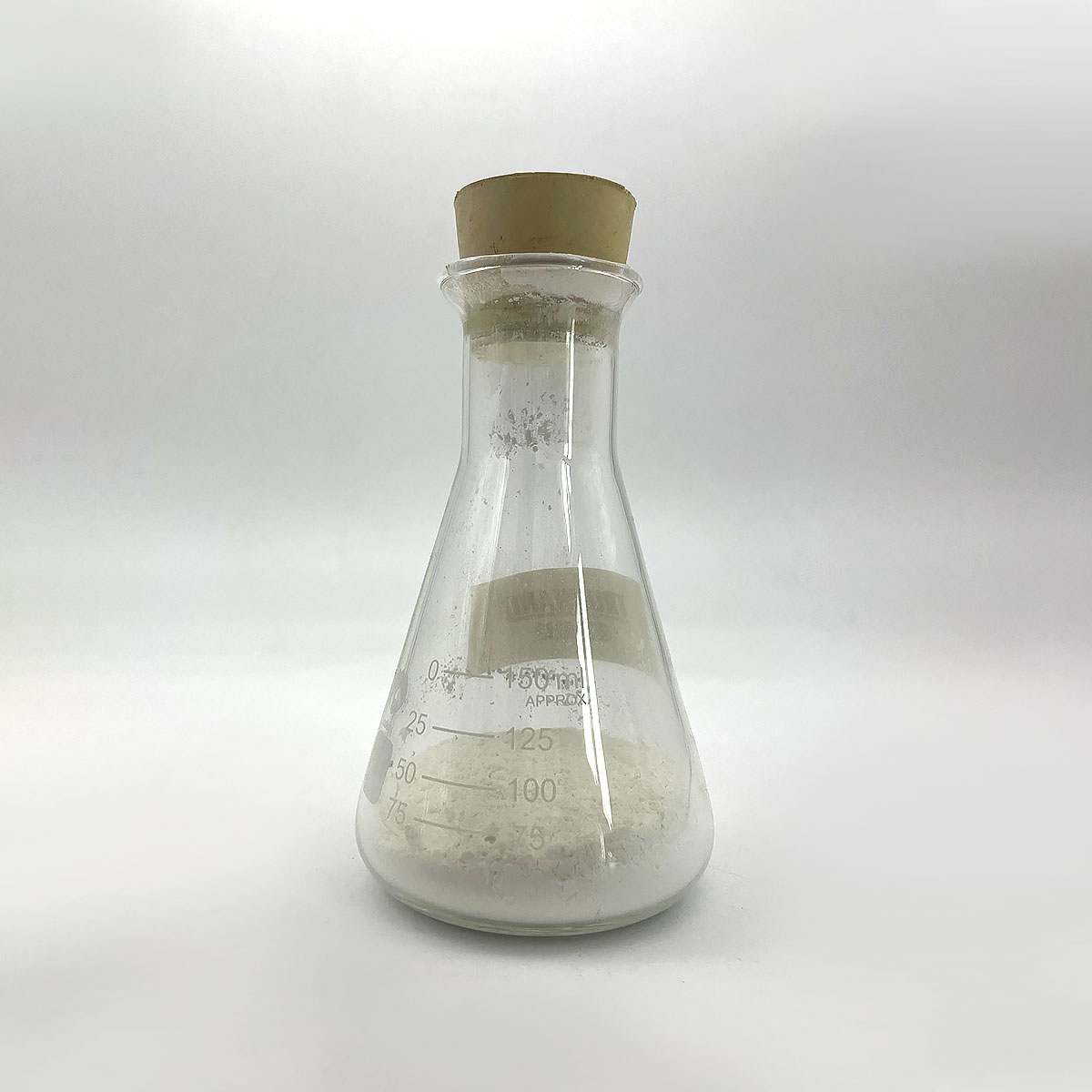

Overview of High Purity 99.99% titanium target for PVD Coating Machine

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of High Purity 99.99% titanium target for PVD Coating Machine

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(High Purity 99.99% titanium target for PVD Coating Machine)

Parameters of High Purity 99.99% titanium target for PVD Coating Machine

Title: High Purity 99.99% Titanium Target for PVD Coating Machines: A Comprehensive Overview

Introduction:

PVD (Physical Vapor Deposition) coating machines play a vital role in the modern manufacturing industry, particularly in enhancing the surface properties of various materials for improved performance and durability. Among the numerous elements utilized in these processes, titanium targets with a purity level of 99.99% hold exceptional significance due to their unique characteristics and superior deposition efficiency. This article delves into the specifications, advantages, and applications of high-purity titanium targets in PVD coating machines.

Material Properties:

Titanium, with the chemical symbol Ti, is a lustrous transition metal known for its lightweight, strength, and corrosion resistance. The 99.99% purity level ensures that the target material is virtually free from impurities, which directly translates to a more consistent and high-quality coating. This purity allows for minimal contamination during the PVD process, resulting in fewer defects and better adherence of the deposited layer.

Melting Point and Thermal Conductivity:

The melting point of pure titanium is approximately 1668°C (3034°F), making it suitable for use in high-temperature PVD environments without significant degradation. Additionally, titanium’s excellent thermal conductivity (21.8 W/m·K) helps dissipate heat effectively, preventing overheating and ensuring optimal operating conditions for the coating machine.

Surface Finish and Morphology:

A high-purity titanium target typically exhibits a smooth, mirror-like finish, which contributes to the uniformity of the deposited coating. The absence of contaminants minimizes surface roughness and ensures a clean interface between the target and the substrate, facilitating efficient adhesion and minimizing stress-induced cracking.

Deposition Rate and Uniformity:

The 99.99% pure titanium target provides a consistent and efficient deposition rate, as impurities do not interfere with the vaporization process. This results in a uniform coating thickness across the substrate, crucial for maintaining the desired mechanical and functional properties in the final product.

Applications:

In PVD coating machines, high-purity titanium is commonly used for a wide range of applications, including:

1. Aerospace: Strengthening and protecting aircraft components against corrosion and wear.

2. Automotive: Enhancing engine parts, brake discs, and body panels with enhanced durability and aesthetics.

3. Medical Devices: Providing biocompatible coatings for implants and surgical instruments to minimize rejection rates.

4. Electronics: Offering corrosion-resistant layers for microelectronics and semiconductor devices.

5. Industrial Machinery: Protecting gears, bearings, and other moving parts from wear and corrosion.

Conclusion:

In summary, a 99.99% pure titanium target is an essential component in PVD coating machines, delivering superior performance, efficiency, and reliability. Its high purity ensures a consistent coating quality, while its material properties contribute to the longevity and effectiveness of the deposition process. As technology advances, the demand for high-purity titanium targets will continue to grow, driving innovation in the field of thin film coatings for various industries.

(High Purity 99.99% titanium target for PVD Coating Machine)

FAQs of High Purity 99.99% titanium target for PVD Coating Machine

Inquiry us