Overview of High purity 99.99% 99.9% Ultrafine 100nm Molybdenum disulfide nano MoS2 powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of High purity 99.99% 99.9% Ultrafine 100nm Molybdenum disulfide nano MoS2 powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

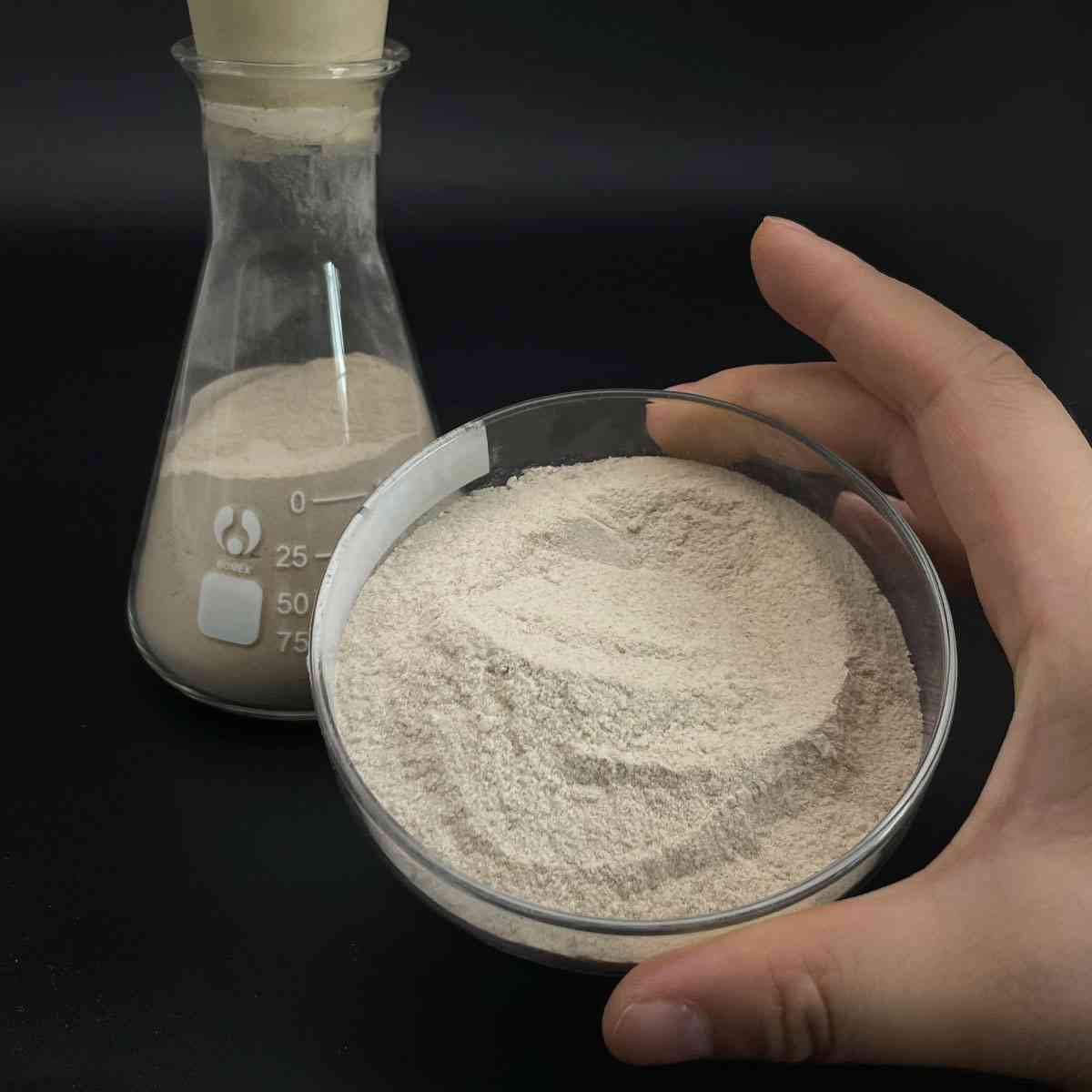

(High purity 99.99% 99.9% Ultrafine 100nm Molybdenum disulfide nano MoS2 powder)

Parameters of High purity 99.99% 99.9% Ultrafine 100nm Molybdenum disulfide nano MoS2 powder

Molybdenum disulfide (MoS2), a captivating material in the nanotechnology realm, boasts an exceptional purity level of 99.99% and 99.9% for high-performance applications. This ultrafine form of MoS2 exists as particles with an incredibly narrow size distribution, typically ranging from 100 nanometers (nm) in diameter, ensuring remarkable properties for various industries.

The high purity of MoS2 is crucial for its inherent electronic, optical, and mechanical characteristics to be fully realized. The 99.99% purity ensures minimal contamination, which is vital for applications where precision and reliability are paramount, such as in electronics, energy storage, and catalysis. The 99.9% purity grade caters to those who require slightly less stringent specifications but still benefit from the superior performance of this nanomaterial.

The nanoscale dimensionality of the particles, at 100nm, significantly enhances the surface area, enabling efficient interactions with substrates and facilitating novel functionalities. This ultrafine structure allows for easy dispersion and integration into various materials, making it suitable for thin-film coatings, composite materials, and advanced sensor technologies.

In terms of physical properties, MoS2 is known for its excellent thermal stability, high electrical conductivity, and strong mechanical strength. At the nanoscale, these attributes are further amplified, contributing to its potential use in microelectronics, supercapacitors, and flexible electronics. Its semiconducting nature, with a direct bandgap, makes it attractive for optoelectronic devices like photodetectors and solar cells.

Moreover, MoS2’s catalytic properties are particularly noteworthy, with its ability to host active sites for various chemical reactions. The ultrathin nanosheets provide an enormous surface-to-volume ratio, enhancing the catalyst’s efficiency in applications such as hydrogen evolution, CO2 reduction, and even fuel cell technology.

In summary, the high purity 99.99% and 99.9% ultrafine 100nm MoS2 nano powder is a versatile material with extraordinary properties that make it an indispensable component in modern technology. Its unique combination of size, purity, and functionality positions it as a key enabler for advancements in fields ranging from energy storage to sensing and catalysis, solidifying its status as a cutting-edge nanomaterial.

(High purity 99.99% 99.9% Ultrafine 100nm Molybdenum disulfide nano MoS2 powder)

FAQs of High purity 99.99% 99.9% Ultrafine 100nm Molybdenum disulfide nano MoS2 powder

Inquiry us