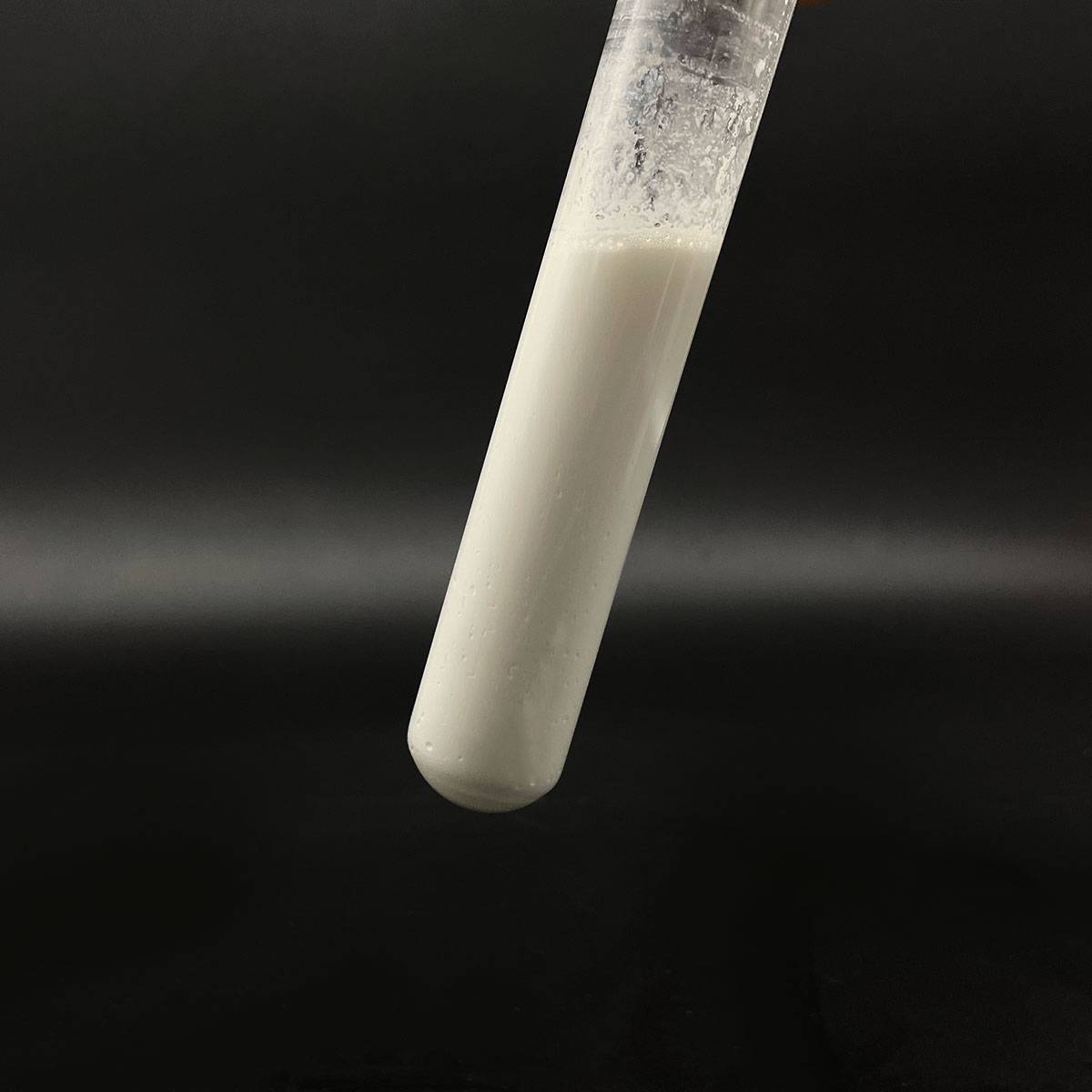

Overview of high purity 99.95% 10.2g/cm3 1 micron-8 micron 1nm industrial grade pure molybdenum powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of high purity 99.95% 10.2g/cm3 1 micron-8 micron 1nm industrial grade pure molybdenum powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(high purity 99.95% 10.2g/cm3 1 micron-8 micron 1nm industrial grade pure molybdenum powder)

Parameters of high purity 99.95% 10.2g/cm3 1 micron-8 micron 1nm industrial grade pure molybdenum powder

High Purity Molybdenum Powder: A Key Industrial Ingredient

Molybdenum, with the chemical symbol Mo, is a vital metallic element known for its exceptional strength, corrosion resistance, and high thermal stability. The powder you are referring to boasts an impressive purity level of 99.95%, ensuring that it meets the stringent requirements of various industrial applications where purity is paramount.

This particular molybdenum powder has a density of 10.2 grams per cubic centimeter (g/cm³), which is a testament to its dense and compact structure. Such a density makes it an excellent choice for applications where weight-bearing capacity and material efficiency are critical factors, such as in aerospace, automotive, and energy industries.

The particle size distribution is crucial for the performance of molybdenum powders, and this product falls within the ideal range of 1 micron to 8 microns. This microscale size ensures that the powder can be easily incorporated into various materials during manufacturing processes, facilitating homogeneous dispersion and enhancing the mechanical properties of the final product. It’s particularly suitable for applications like metal matrix composites, coatings, and advanced ceramics, where fine grain structures contribute to improved wear resistance and strength.

Furthermore, the mention of “1nm” indicates that the powder may also possess sub-nano characteristics, providing even greater surface area and reactivity, which can be advantageous in applications that require enhanced catalytic or diffusion properties, such as catalysts and electronic components.

As an industrial-grade material, this molybdenum powder adheres to strict quality control standards, ensuring consistency and reliability in performance across multiple batches. The absence of impurities minimizes contamination and processing steps, ultimately translating to cost savings and reduced waste for end-users.

In summary, the high purity, density, and particle size distribution of this molybdenum powder make it an attractive option for industries that demand precision, durability, and efficiency. From aerospace engineering to electronics, this material finds its place in various sectors where its unique properties contribute significantly to the overall functionality and longevity of products. By selecting this 99.95% pure, 10.2 g/cm³, 1 micron to 8 micron, and 1nm industrial-grade molybdenum powder, manufacturers can expect superior performance and reliability in their applications.

(high purity 99.95% 10.2g/cm3 1 micron-8 micron 1nm industrial grade pure molybdenum powder)

FAQs of high purity 99.95% 10.2g/cm3 1 micron-8 micron 1nm industrial grade pure molybdenum powder

Inquiry us