Overview of High Purity 99.9% Nano Molybdenum Dioxide MoO2 Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of High Purity 99.9% Nano Molybdenum Dioxide MoO2 Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

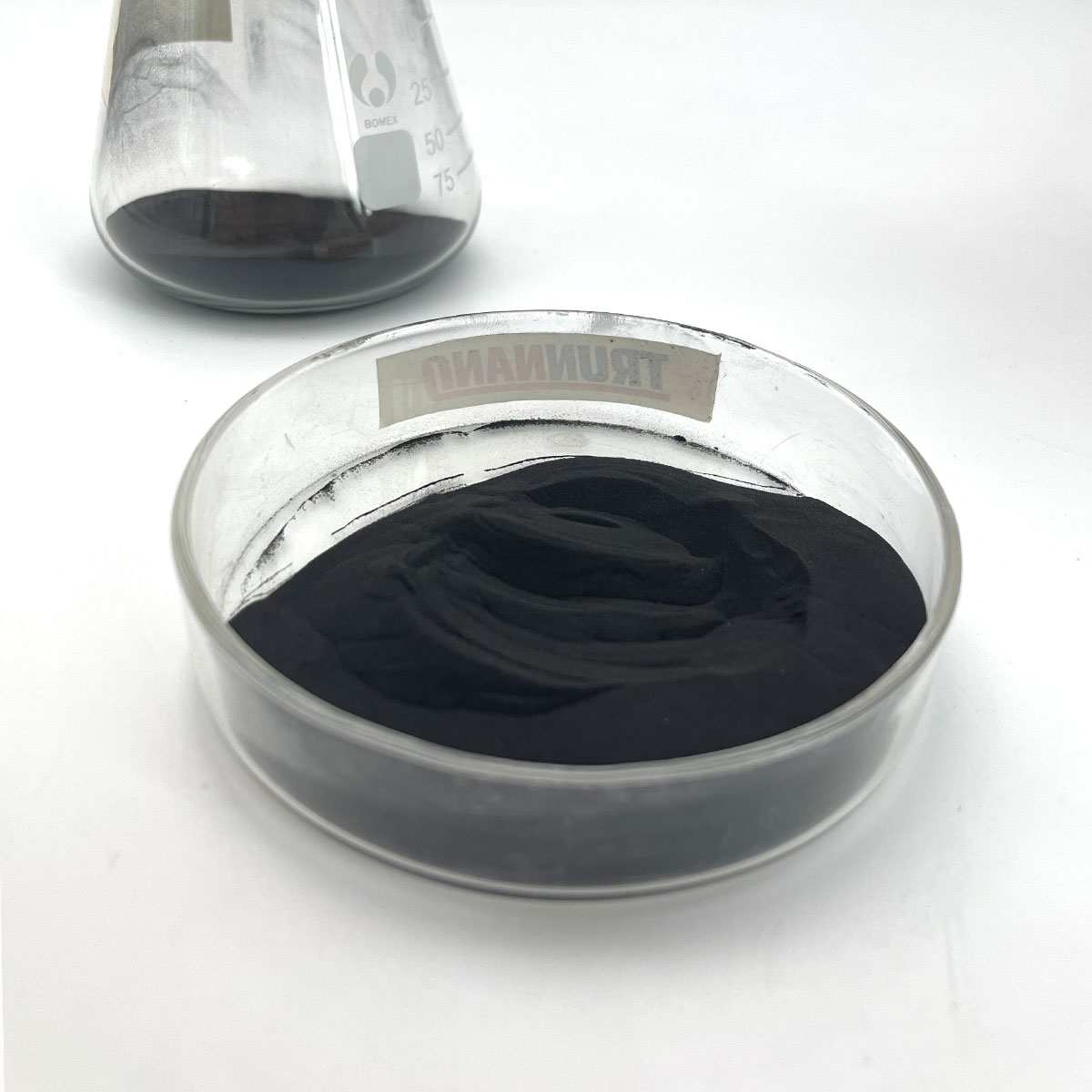

(High Purity 99.9% Nano Molybdenum Dioxide MoO2 Powder)

Parameters of High Purity 99.9% Nano Molybdenum Dioxide MoO2 Powder

High Purity 99.9% Nano Molybdenum Dioxide (MoO2) Powder: A Comprehensive Overview

Molybdenum dioxide (MoO2), an essential material in various industrial applications, is a compound of molybdenum and oxygen, with a chemical formula that denotes the intimate bonding between these elements. When synthesized at the nanoscale, it exhibits unique properties due to its reduced grain size and increased surface area, which significantly impact its performance. The 99.9% purity grade ensures a high-quality product with minimal impurities, making it ideal for demanding applications.

The nanostructured form of molybdenum dioxide has a particle size ranging from 1 to 100 nanometers, providing exceptional physical and chemical characteristics compared to its bulk counterpart. This nano-size enables better dispersion, improved reactivity, and enhanced catalytic activity. The nanoparticles have a high surface-to-volume ratio, which facilitates efficient absorption and release of energy, making it suitable for energy storage devices like lithium-ion batteries.

In electronic applications, molybdenum dioxide is used as a conductive additive in ceramic varistors and as a catalyst in thin-film transistors due to its excellent electrical conductivity and stability. The high purity ensures consistent performance and longevity in these devices, where any trace impurities could compromise their functionality.

In the field of optoelectronics, nano-MoO2 finds use as a transparent conducting oxide (TCO), particularly in touchscreens and solar cells. Its unique combination of high transparency and electrical conductivity makes it a promising material for next-generation display technologies. The 99.9% purity ensures minimal scattering of light, enhancing visual clarity and overall device efficiency.

In the realm of chemical sensing, molybdenum dioxide acts as a sensitive gas sensor, detecting molecules such as ammonia, hydrogen sulfide, and even explosives. The nanoscale structure plays a crucial role in enhancing the sensitivity and selectivity of these sensors. High purity ensures accurate readings and minimal interference from impurities.

Environmental remediation is another area where nano-MoO2 demonstrates its potential. It can be employed as a catalyst in water and air purification processes, breaking down pollutants into less harmful substances. The high purity ensures optimal catalytic performance and reduces the formation of byproducts.

In the field of lubrication, nano-MoO2 can serve as a high-performance additive, improving the wear resistance and reducing friction in various mechanical systems. Its unique properties contribute to extended equipment life and reduced maintenance costs.

Lastly, molybdenum dioxide is also utilized in the production of catalysts for the automotive industry, enhancing fuel efficiency and reducing emissions. The high purity grade ensures reliable performance in harsh engine environments.

In conclusion, the 99.9% purity nano-molybdenum dioxide powder offers exceptional properties that make it a sought-after material in numerous industries, from electronics to environmental science. Its high purity guarantees consistent performance and minimizes any unwanted side effects, making it a critical component in the advancement of technology and sustainability.

(High Purity 99.9% Nano Molybdenum Dioxide MoO2 Powder)

FAQs of High Purity 99.9% Nano Molybdenum Dioxide MoO2 Powder

Inquiry us