Overview of Good Corrosion Resistance China Tungsten Spring Wire With Top Quality

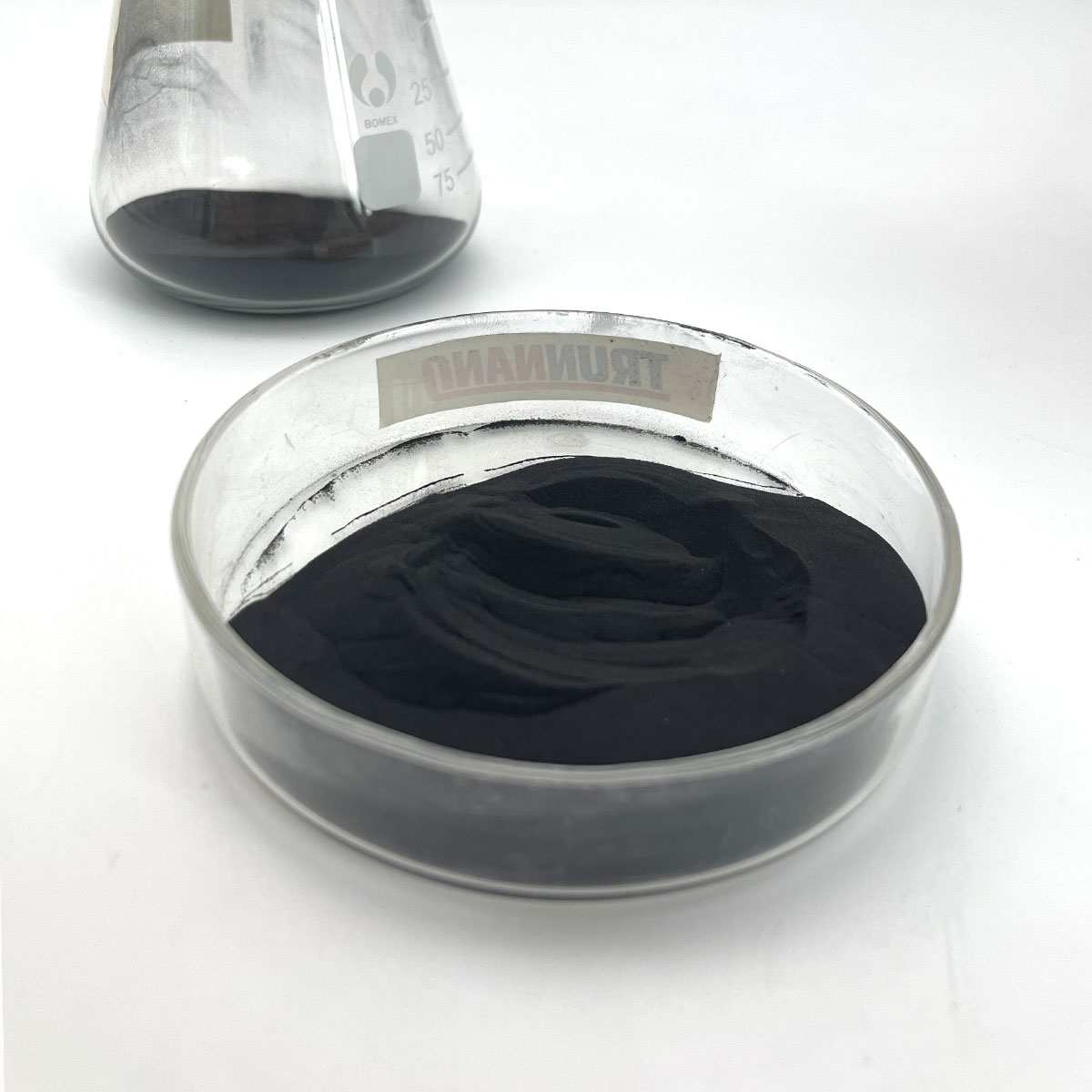

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Good Corrosion Resistance China Tungsten Spring Wire With Top Quality

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Good Corrosion Resistance China Tungsten Spring Wire With Top Quality)

Parameters of Good Corrosion Resistance China Tungsten Spring Wire With Top Quality

Title: High-Quality Tungsten Spring Wire with Excellent Corrosion Resistance from China: A Comprehensive Overview

In today’s fast-paced industrial landscape, the demand for reliable and durable materials has escalated. Among these, China’s tungsten spring wire stands out due to its exceptional corrosion resistance and top-notch quality parameters. This article delves into the characteristics, manufacturing process, and benefits of this versatile material.

Tungsten, known for its unparalleled strength and stability, is the base component of tungsten spring wire. It boasts a high melting point, which makes it ideal for applications where extreme temperatures and harsh environments are prevalent. The combination of tungsten’s inherent properties with precision engineering results in a product that can withstand corrosive elements such as acids, alkalis, and humidity without compromising its performance.

The manufacturing process of high-quality Chinese tungsten spring wire is a testament to its precision and attention to detail. It begins with the selection of pure tungsten ingots, which undergo a series of refining steps to remove impurities. The ingots are then rolled into thin wires using advanced cold drawing techniques, ensuring uniformity in diameter and tensile strength. The wires are subjected to heat treatment and further tempering to optimize their mechanical properties, including elasticity and fatigue resistance.

One of the key factors that set Chinese tungsten spring wire apart is its corrosion resistance. Thanks to the use of specialized coatings or surface treatments, such as electroplating or anodizing, the wire develops a protective barrier that prevents chemical reactions that would otherwise weaken the material. This not only extends the wire’s lifespan but also maintains its accurate dimensions and shape over time, crucial for precision applications.

In terms of quality parameters, the top-of-the-line tungsten spring wire from China adheres to stringent international standards. These include precise specifications for diameter, hardness, elongation, and yield strength, ensuring consistent performance across different industries. The wire is regularly tested for dimensional accuracy, microstructure, and mechanical properties, guaranteeing its reliability in demanding applications like aerospace, automotive, and medical devices.

The benefits of using Chinese tungsten spring wire with excellent corrosion resistance are numerous. Firstly, it reduces maintenance costs by minimizing the need for frequent replacements due to premature degradation. Secondly, it enhances safety, as corroded components can pose risks in high-stress situations. Lastly, it contributes to improved efficiency, as the wire’s consistent performance ensures optimal functioning of equipment and machinery.

In conclusion, China’s tungsten spring wire with its unparalleled corrosion resistance and top-quality parameters represents a cutting-edge solution for industries seeking long-lasting, dependable components. Its robustness, combined with the country’s reputation for efficient production, makes it a preferred choice for businesses worldwide. As technology continues to advance, this material will undoubtedly remain at the forefront of innovation, enabling engineers and manufacturers to push boundaries and deliver superior products.

(Good Corrosion Resistance China Tungsten Spring Wire With Top Quality)

FAQs of Good Corrosion Resistance China Tungsten Spring Wire With Top Quality

Inquiry us