Titanium steel alloy plate is a high-performance composite material that incorporates the excellent properties of titanium and steel. Titanium is known for its high stamina, reduced thickness, deterioration resistance and excellent biocompatibility, while steel has excellent mechanical strength and processability. Through a details alloying process, titanium steel alloy plates not just inherit the advantages of these 2 materials but likewise have higher general performance. Its major performance features include high stamina and lightweight, reduced density yet extremely high stamina, appropriate for minimizing weight while keeping sufficient architectural strength, exceptionally corrosion-resistant, and can preserve excellent performance even in severe settings. Suitable for aquatic engineering and chemical tools and various other fields; excellent thermal stability can still keep great mechanical properties at high temperatures, appropriate for aerospace and high-temperature industrial atmospheres; excellent handling performance can be cut and welded by conventional steel handling techniques and molding to assist in the manufacture of complex-shaped parts. Titanium steel alloy plates are extensively utilized in several areas, including aerospace (made use of to manufacture aircraft architectural parts, engine components, etc, to enhance fuel efficiency and safety and security), ocean engineering (made use of to develop deep-sea boring platforms, ship shells, and so on, to withstand salt water corrosion), vehicle manufacturing (particularly in the field of electric cars, made use of to manufacture body and chassis components to achieve lightweight layout) and medical devices (utilized to make fabricated joints, dental implants, and so on, to enhance person comfort and service life).

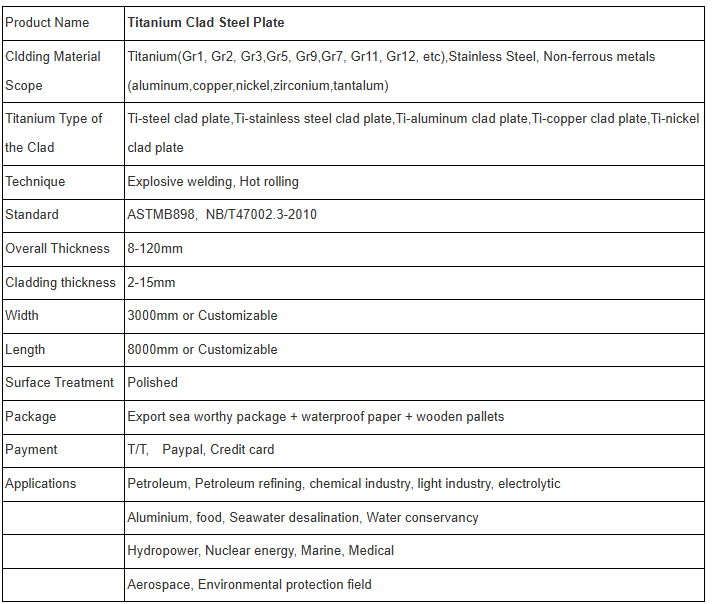

(Parameter of Titanium Clad Steel Plate)

Market Review

In recent times, with the healing of the global economic situation and technical advancement, the need for titanium steel alloy plates has actually shown a stable growth fad. According to market research, the international titanium steel alloy plate market size has actually gotten to about US$ 5 billion in 2024 and is expected to reach about US$ 7.5 billion by 2028, with a typical annual substance development rate of roughly 8%. This growth is mostly as a result of its irreplaceability popular applications and the raising demand for much more reliable and much safer products.

Technology development and innovation

Technological advancement is just one of the key elements driving the growth of the titanium steel alloy plate market. Leading business such as TRUNNANO continue to purchase r & d and are committed to enhancing the efficiency of products, decreasing manufacturing costs, and expanding the range of applications. For instance, by maximizing the percentage of alloy parts and using sophisticated warmth therapy processes, the mechanical stamina and rust resistance of titanium steel alloy plates can be considerably enhanced, making them carry out better in severe environments. In addition, the application of nanotechnology has actually likewise brought brand-new opportunities to titanium steel alloy plates, such as boosting surface hardness, enhancing conductivity and magnetic residential or commercial properties, and additionally widening its application areas. With the continuous development of modern technology, titanium steel alloy plates are expected to show their special worth in extra emerging fields.

Growth of application areas

Titanium steel alloy plates have shown wonderful application capacity in several sectors as a result of their distinct residential or commercial properties. In the area of aerospace, it is used to produce airplane architectural components, engine components, and so on, assisting to reduce weight and improve gas effectiveness; in aquatic design, the corrosion resistance of titanium steel alloy plates makes it a perfect choice for developing deep-sea drilling systems, ships Perfect for real estates; in the vehicle industry, with the quick growth of the electrical automobile market, the need for light-weight products is boosting, and titanium steel alloy plates have become a preferred choice due to their outstanding efficiency; and in the clinical field, because of their excellent organic As a result of their compatibility and anti-infection abilities, titanium steel alloy plates are utilized to make medical devices such as fabricated joints and dental implants, enhancing the lifestyle of people. The expansion of these application fields not only advertises the development of market need yet additionally offers broad space for the growth of titanium steel alloy plates.

Regional market analysis

From the perspective of local circulation, the Asia-Pacific region is the globe’s largest customer market for titanium steel alloy plates, specifically China, Japan and South Korea. These 3 countries have solid manufacturing capacities in the areas of car manufacturing, electronics industry, aerospace and other areas, and are very crucial to state-of-the-art sectors. Efficiency products remain in massive need. The North American market is generally focused in the aerospace and protection market, while the European market excels in auto production and high-end manufacturing. Although South America, the Center East and Africa presently have a smaller market share, as a result of the increased industrialization process in these regions, the growth of infrastructure building and production is expected to bring new development points to titanium steel alloy plates. Differences in market attributes and demands in various areas pressure firms to embrace versatile market methods to adapt to varied market demands.

( TRUNNANO Titanium Clad Steel Plate)

Future trends and challenges

Looking to the future, with the proceeded healing of the international economic climate and the rapid advancement of science and technology, the titanium steel alloy plate market will continue to preserve a growth trend. Technological development will remain to be the core driving pressure for market growth, especially the application of nanotechnology and smart manufacturing innovation, which will certainly additionally boost product efficiency, reduce prices, and broaden the range of applications. Nevertheless, the marketplace likewise encounters some difficulties, such as resources cost changes, high production expenses, and increased market competition. In order to cope with these challenges, business such as TRUNNANO need to boost financial investment in r & d, optimize production processes, enhance production effectiveness, and, at the exact same time, strengthen teamwork with downstream clients to create new items and check out new markets collectively. On top of that, lasting development and environmental management are likewise key instructions for future development. By using eco-friendly products and innovations, we can decrease power usage and waste exhausts throughout the manufacturing process to achieve a great deal of financial and environmental benefits.

Provider

TRUNNANO is a supplier of nano materials with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about clad plate welding, please feel free to contact us and send an inquiry.(sales8@nanotrun.com)

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us