Overview of Ferro-molybdenum Ferromolybdenum Ferromolybdenum Low Carbon Ferro-molybdenum Femo Lump Ferro Molybdenum Ferromolybdenum

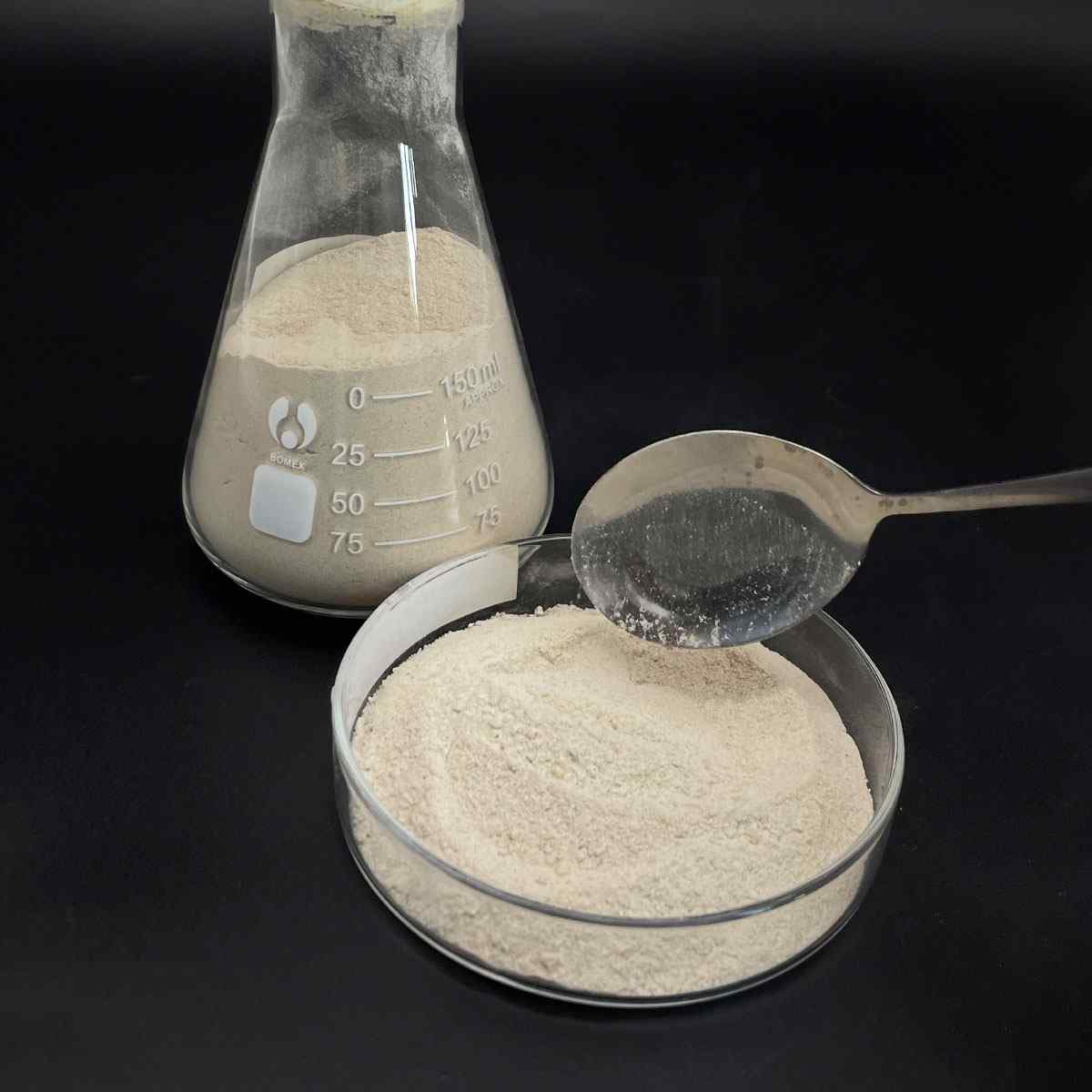

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Ferro-molybdenum Ferromolybdenum Ferromolybdenum Low Carbon Ferro-molybdenum Femo Lump Ferro Molybdenum Ferromolybdenum

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Ferro-molybdenum Ferromolybdenum Ferromolybdenum Low Carbon Ferro-molybdenum Femo Lump Ferro Molybdenum Ferromolybdenum)

Parameters of Ferro-molybdenum Ferromolybdenum Ferromolybdenum Low Carbon Ferro-molybdenum Femo Lump Ferro Molybdenum Ferromolybdenum

Ferromolybdenum, a combination of iron and molybdenum, is a high-performance alloy that boasts exceptional strength, durability, and corrosion resistance. This material finds extensive applications in various industries due to its unique properties.

The term “ferro-molybdenum” refers to an iron-based compound where molybdenum is present as a significant element. Molybdenum, with its atomic number 42, enhances the metal’s strength by forming strong chemical bonds with iron, improving its wear resistance and resistance to high temperatures. The addition of molybdenum also results in better creep resistance, meaning it maintains its strength even under prolonged stress.

Low carbon ferromolybdenum, on the other hand, contains a lower concentration of carbon compared to regular ferromolybdenum. This reduces brittleness and increases the material’s ductility, making it more suitable for applications where flexibility and toughness are crucial. The lower carbon content also aids in reducing the likelihood of internal stresses, which can lead to cracking or deformation over time.

Ferromolybdenum lumps, often found in their natural state, are irregularly shaped blocks or masses of the alloy. These lumps are typically used as a raw material in the manufacturing process, where they are further processed into bars, sheets, or wires to meet specific industry requirements.

Ferromolybdenum is often utilized in industries like aerospace, automotive, power generation, and oil and gas exploration. It is commonly employed in the construction of engine components, bearings, valves, and pipes, where high-temperature and high-pressure environments are prevalent. Its resistance to oxidation and corrosion makes it ideal for use in harsh conditions, ensuring long-lasting performance.

In the aerospace industry, ferromolybdenum is used for jet engine parts, such as compressor blades, due to its ability to withstand extreme temperatures and maintain structural integrity. In the automotive sector, it is employed in exhaust systems and brake parts, benefiting from its strength and heat resistance.

In the energy sector, ferromolybdenum plays a vital role in the production of steam turbines and nuclear reactors, where its corrosion-resistant properties ensure the longevity of critical components. Additionally, it is used in oil drilling equipment to protect against wear and tear in harsh underground environments.

The parameters that define ferromolybdenum include its chemical composition (iron and molybdenum ratio), mechanical properties like yield strength, tensile strength, and hardness, as well as its microstructure. These factors are carefully controlled during the manufacturing process to optimize the alloy’s performance for different applications.

In conclusion, ferromolybdenum is a versatile and indispensable material in modern engineering, offering a blend of strength, durability, and resistance to harsh conditions. Its unique combination of properties makes it a preferred choice across various sectors, ensuring reliability and efficiency in demanding applications.

(Ferro-molybdenum Ferromolybdenum Ferromolybdenum Low Carbon Ferro-molybdenum Femo Lump Ferro Molybdenum Ferromolybdenum)

FAQs of Ferro-molybdenum Ferromolybdenum Ferromolybdenum Low Carbon Ferro-molybdenum Femo Lump Ferro Molybdenum Ferromolybdenum

Inquiry us