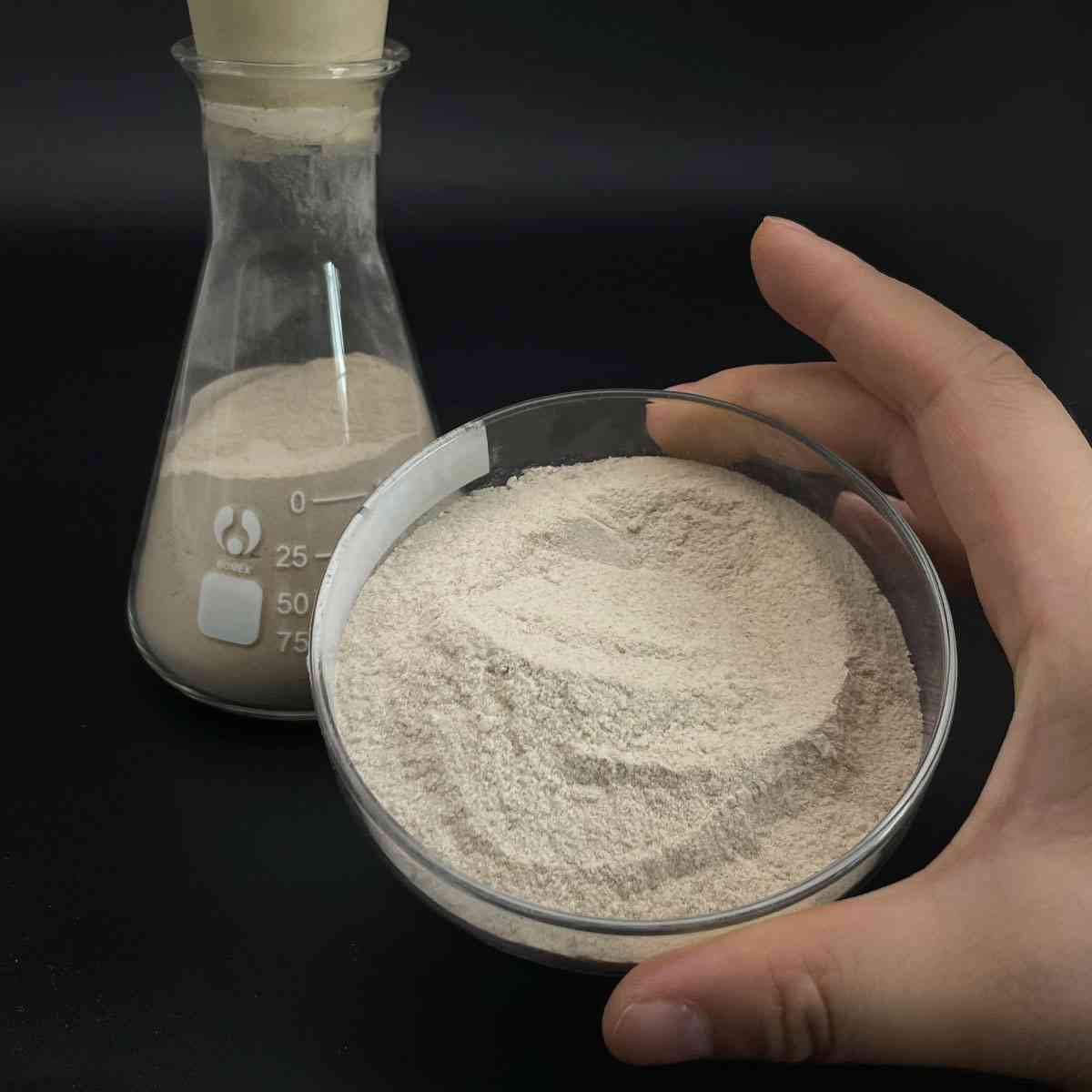

Overview of FeNb 65/60/55/50 ferro niobium powder lump for welding rods wires and steel with factory

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of FeNb 65/60/55/50 ferro niobium powder lump for welding rods wires and steel with factory

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(FeNb 65/60/55/50 ferro niobium powder lump for welding rods wires and steel with factory )

Parameters of FeNb 65/60/55/50 ferro niobium powder lump for welding rods wires and steel with factory

Ferro-Niobium (FeNb) is a unique alloy composed primarily of iron (Fe) and niobium (Nb), known for its exceptional properties that make it an ideal material in various applications, particularly in the welding industry. The FeNb 65/60/55/50 grade refers to a specific composition range, where the percentage of niobium ranges from 65% to 50%, with iron making up the remaining percentage. This variation allows for different grades with distinct characteristics tailored to specific requirements.

The FeNb powder lump, often used for welding rods, wires, and steel, offers several advantages. First, its high niobium content enhances the alloy’s strength and ductility, making it resistant to stress corrosion and fatigue. This property is crucial in demanding environments where components are subjected to repeated stress or exposure to corrosive elements.

Secondly, the fine-grained structure resulting from the powder form improves the welding process. The uniform particle size promotes better flow during melting, leading to a more consistent weld bead and enhanced joining strength. The powder also facilitates better penetration, reducing the need for filler materials and minimizing heat-affected zones, which can cause distortion or weaken the base metal.

In terms of thermal conductivity, FeNb has excellent heat transfer capabilities, which help to minimize heat input and minimize thermal stresses during welding. This results in reduced thermal cracking and improved surface finish on the welded parts. Additionally, the alloy’s low coefficient of thermal expansion reduces the likelihood of cold cracks after cooling, further enhancing the quality of the weld.

For steel applications, FeNb powder lump is employed in various ways. It can be used as a flux-cored arc welding (FCAW) electrode, providing a stable arc and producing deep penetration welds. The alloy can also be incorporated into shielded metal arc welding (SMAW) fluxes, improving the arc stability and weld pool behavior. Furthermore, it finds application in gas tungsten arc welding (GTAW) due to its excellent machinability and resistance to tungsten carbide erosion.

Factory parameters for FeNb 65/60/55/50 powder lump production involve strict control over the chemical composition, particle size distribution, and morphology. These parameters ensure consistent product quality and adherence to industry standards. The manufacturing process may include techniques such as gas atomization, mechanical milling, or electrostatic spraying to achieve the desired particle size and shape.

In summary, FeNb 65/60/55/50 ferro-niobium powder lump is a versatile material for welding applications due to its superior strength, ductility, thermal conductivity, and resistance to corrosion. Its use in welding rods, wires, and steel products leads to improved weld quality, reduced heat input, and enhanced performance in demanding environments. Factory parameters play a crucial role in ensuring the consistent delivery of high-quality FeNb powders for various industrial needs.

(FeNb 65/60/55/50 ferro niobium powder lump for welding rods wires and steel with factory )

FAQs of FeNb 65/60/55/50 ferro niobium powder lump for welding rods wires and steel with factory

Inquiry us