Overview of Factory supply 50 mm chromium molybdenum white iron bars ingots whole

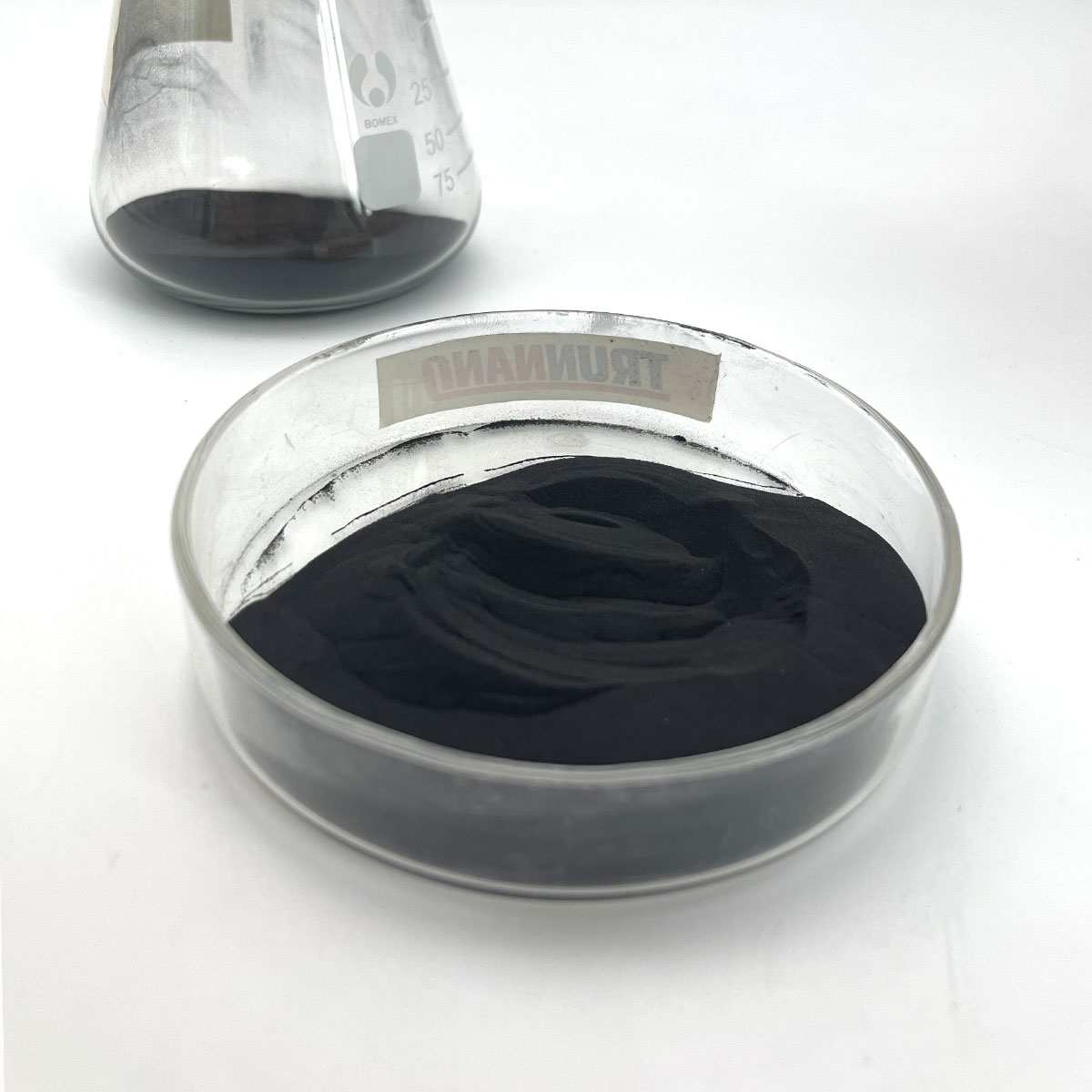

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Factory supply 50 mm chromium molybdenum white iron bars ingots whole

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Factory supply 50 mm chromium molybdenum white iron bars ingots whole )

Parameters of Factory supply 50 mm chromium molybdenum white iron bars ingots whole

Title: Factory Supply of 50mm Chromium Molybdenum White Iron Bars Ingots: A Comprehensive Overview

Introduction:

Our specialized factory is proud to offer high-quality 50mm chromium molybdenum (CrMo) white iron bars in the form of ingots, designed for a wide range of industrial applications. These bars, characterized by their exceptional strength, durability, and corrosion resistance, have become a popular choice among engineers and fabricators seeking a premium material for their projects.

Material Composition:

Chromium Molybdenum steel, or CrMo, is a versatile alloy containing approximately 1% to 2.5% chromium and varying amounts of molybdenum, typically around 0.25% to 1%. This combination provides the bars with enhanced mechanical properties, including high tensile strength, wear resistance, and excellent creep resistance. The addition of molybdenum also contributes to improved thermal stability, making it suitable for applications subjected to elevated temperatures.

Manufacturing Process:

Our ingots are produced through a meticulous process that begins with the selection of high-purity raw materials. We employ state-of-the-art metallurgical techniques to refine and blend the chromium and molybdenum components, ensuring uniform distribution throughout the bars. The molten metal is then cast into solid ingots, which undergo a controlled cooling process to achieve the desired microstructure and minimize internal stresses.

Quality Control:

At our factory, we adhere to strict quality control measures to guarantee the consistency and reliability of our products. Each ingot undergoes rigorous testing, including chemical composition analysis, mechanical testing, and dimensional checks. Our bars conform to international standards such as ASTM A-36, EN 10083, or JIS G4053, ensuring that they meet the highest industry standards.

Applications:

The 50mm CrMo white iron bars are widely used across various sectors, from power generation and petrochemicals to aerospace and automotive industries. They find application in components subjected to high stress, such as bearings, gears, valves, and turbine blades. Their superior strength-to-weight ratio makes them ideal for heavy-duty machinery, and their resistance to wear and corrosion ensures long-lasting performance.

Customization:

While our standard offering is 50mm in diameter, we can also provide custom sizes upon request, catering to the unique requirements of our clients. Our experienced team can work closely with you to determine the most suitable dimensions and surface finish, ensuring a seamless integration into your manufacturing processes.

Supply Chain:

We understand the importance of timely delivery and efficient logistics. Our factory is equipped with modern storage facilities and a reliable distribution network, allowing us to deliver the 50mm CrMo white iron bars ingots to customers worldwide promptly and reliably.

Conclusion:

In summary, our factory is dedicated to providing top-quality 50mm chromium molybdenum white iron bars ingots, backed by stringent quality control and customization capabilities. These bars are the epitome of strength, durability, and versatility, making them an indispensable material choice for demanding industrial applications. Contact us today to learn more about our offerings and how we can support your manufacturing needs.

(Factory supply 50 mm chromium molybdenum white iron bars ingots whole )

FAQs of Factory supply 50 mm chromium molybdenum white iron bars ingots whole

Inquiry us