Overview of Factory supplies High quality Molybdenum trioxide/Trioxomolybdenum CAS 1313-27-5

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Factory supplies High quality Molybdenum trioxide/Trioxomolybdenum CAS 1313-27-5

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Factory supplies High quality Molybdenum trioxide/Trioxomolybdenum CAS 1313-27-5)

Parameters of Factory supplies High quality Molybdenum trioxide/Trioxomolybdenum CAS 1313-27-5

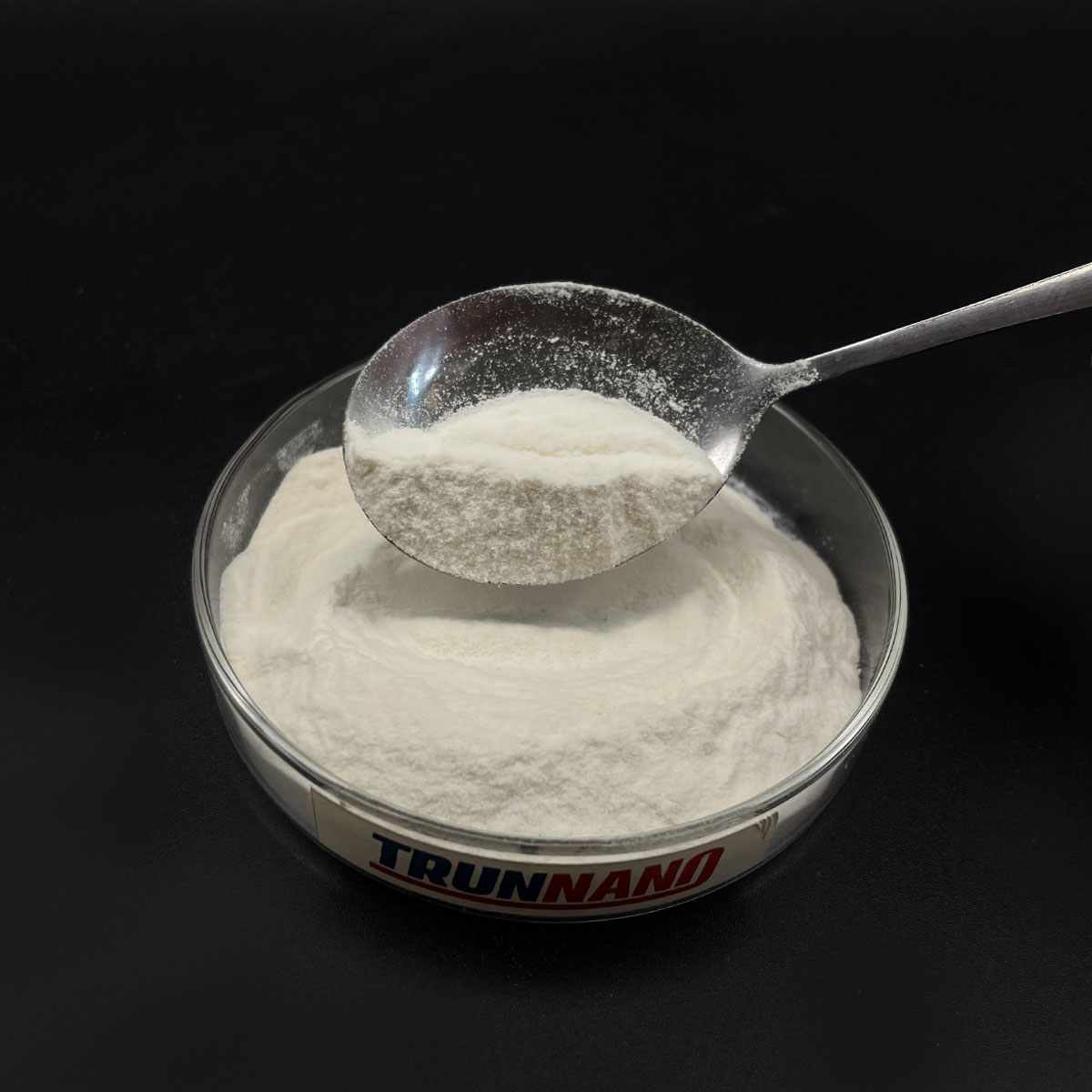

Molybdenum trioxide, also known as Trioxomolybdenum or MoO3 (CAS number 1313-27-5), is a high-performance inorganic compound that finds extensive applications across various industries due to its unique properties and versatile nature. It is an essential material synthesized by combining molybdenum with oxygen, resulting in a white crystalline solid with a chemical formula of MoO3.

As a key industrial compound, molybdenum trioxide is renowned for its exceptional thermal stability, high melting point (about 2860°C), and strong chemical inertness. These characteristics make it resistant to corrosion and enable it to maintain its structure under extreme conditions, making it ideal for use in high-temperature environments such as catalysts, refractories, and ceramic applications.

One of the primary applications of molybdenum trioxide is in the field of catalysis, where it serves as a crucial component in the production of fertilizers, petrochemicals, and even automotive emissions control systems. Its ability to form stable metal-oxide bonds allows it to enhance the efficiency and selectivity of chemical reactions, thus improving overall process performance.

In the electronics industry, molybdenum trioxide is employed as a thin film material in semiconductor devices, where it offers excellent electrical insulation and contributes to the formation of high-quality dielectric layers. This property makes it an indispensable component in the fabrication of modern electronic components like microprocessors and memory devices.

Moreover, molybdenum trioxide plays a significant role in the production of high-strength alloys, particularly in aircraft engines and aerospace components. Its presence in these alloys improves their wear resistance, creep strength, and high-temperature performance, ensuring durability and reliability in demanding aerospace applications.

The compound is also used in the manufacturing of glass and ceramic products, where it enhances the mechanical properties, heat resistance, and optical clarity. Additionally, molybdenum trioxide is employed in the pigment industry, providing a bright blue or green color to ceramics, enamels, and pigmented plastics.

When it comes to the supply of molybdenum trioxide, our factory adheres to the highest standards of quality and purity. We ensure that every batch is carefully processed through rigorous testing procedures to meet international standards, eliminating any impurities or contaminants. Our commitment to excellence extends from the selection of raw materials to the final product, ensuring that customers receive a consistent and reliable supply of high-quality MoO3.

In conclusion, molybdenum trioxide is a versatile and indispensable material with a myriad of applications in various sectors. Its unique properties make it a sought-after ingredient in industries ranging from electronics to aerospace, and our factory is dedicated to providing the highest quality product without any compromise on performance or consistency. If you require molybdenum trioxide for your specific needs, trust us to deliver a superior product that meets and exceeds your expectations.

(Factory supplies High quality Molybdenum trioxide/Trioxomolybdenum CAS 1313-27-5)

FAQs of Factory supplies High quality Molybdenum trioxide/Trioxomolybdenum CAS 1313-27-5

Inquiry us