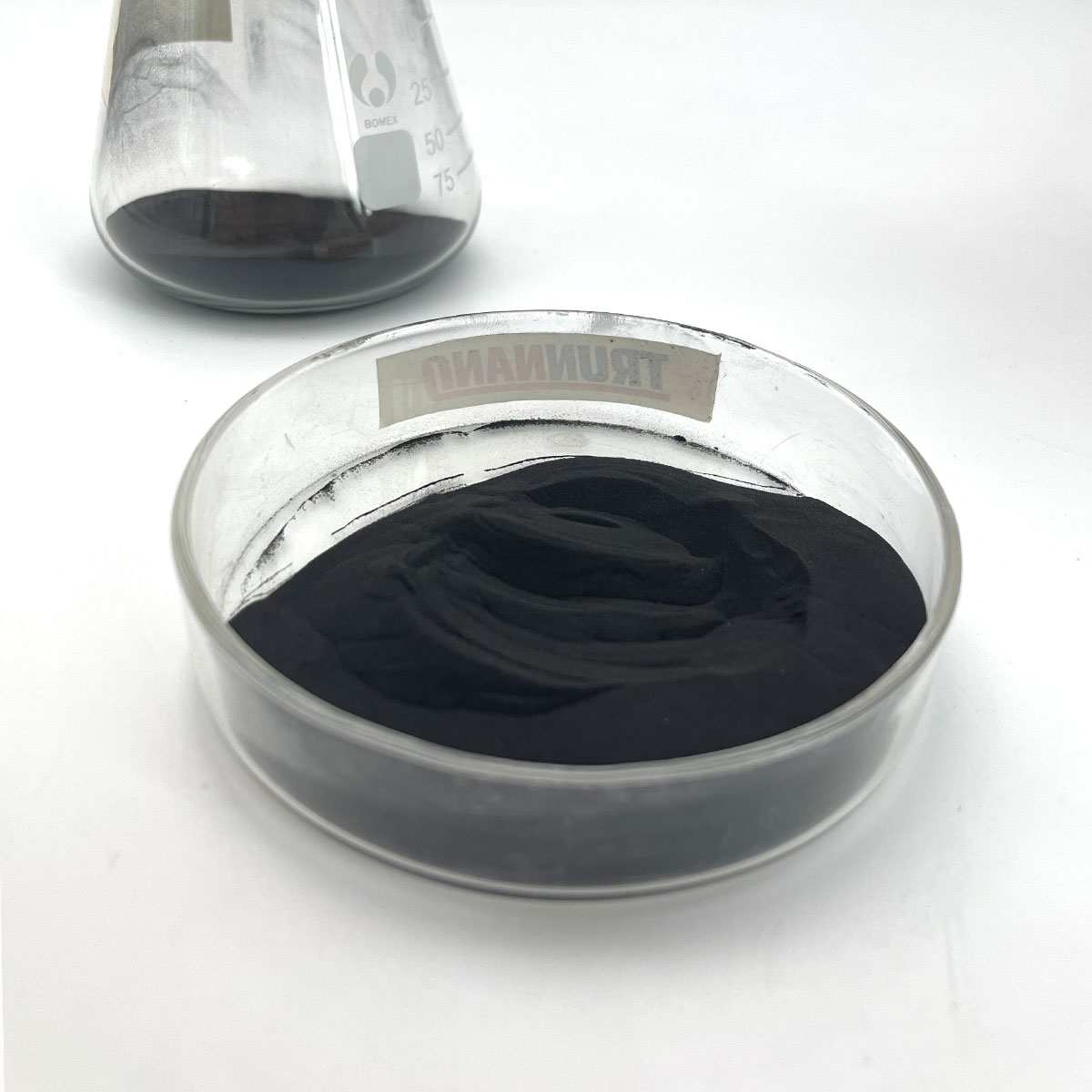

Overview of Factory molybdenum oxide powder MoO3 nanoparticles MoO3 nanopowder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Factory molybdenum oxide powder MoO3 nanoparticles MoO3 nanopowder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Factory molybdenum oxide powder MoO3 nanoparticles MoO3 nanopowder)

Parameters of Factory molybdenum oxide powder MoO3 nanoparticles MoO3 nanopowder

Molybdenum oxide (MoO3) is a chemically inert, metallic oxide compound of molybdenum and oxygen, with the chemical formula MoO3. It is an important material in various industrial applications due to its unique properties, such as high thermal stability, non-toxicity, and excellent electrical conductivity, especially when in the form of nanoparticles.

Nanoparticles of molybdenum trioxide, or MoO3 nanopowder, have gained significant attention in recent years due to their superior surface area, reactivity, and enhanced catalytic properties compared to the bulk material. These particles, typically having dimensions in the nanometer range, exhibit unique characteristics that differentiate them from their larger counterparts.

One of the key features of MoO3 nanoparticles is their large surface-to-volume ratio, which allows for increased interaction with reactants in chemical processes. This makes them highly effective in applications like photocatalysis, where they can split water molecules into hydrogen and oxygen under sunlight, generating clean energy. Additionally, they are employed in gas sensors, where their sensitivity to specific gases, such as ammonia or formaldehyde, is heightened due to their nanostructure.

In electronics, MoO3 nanoparticles are used as dielectric materials in thin film transistors and capacitors, providing improved performance in terms of miniaturization and energy efficiency. They also find applications in memory devices, where their non-volatile nature contributes to data storage.

The synthesis methods for obtaining MoO3 nanoparticles include sol-gel, hydrothermal, chemical vapor deposition (CVD), and physical vapor deposition (PVD). Each technique offers different advantages in terms of particle size control, purity, and yield. For instance, hydrothermal synthesis results in highly crystalline particles, while CVD provides better conformal coatings on substrates.

Environmental remediation is another area where MoO3 nanoparticles play a crucial role. Their ability to adsorb heavy metals and organic pollutants from water and air makes them suitable for use in water purification and air filtration systems. Moreover, their photocatalytic activity aids in decomposing toxic compounds, contributing to a cleaner environment.

In the field of energy storage, MoO3 nanoparticles are employed in lithium-ion batteries as cathode materials. They exhibit high capacity and good cycling stability, making them promising candidates for next-generation rechargeable batteries.

In summary, molybdenum oxide nanoparticles, or MoO3 nanopowder, exhibit exceptional properties that make them versatile in numerous applications, ranging from electronics and energy storage to environmental remediation and photocatalysis. Their unique size-dependent characteristics open up new possibilities for innovation and contribute to sustainable technologies. As research continues to advance, it is expected that MoO3 nanoparticles will play an increasingly important role in various industries, driving progress and efficiency in the modern world.

(Factory molybdenum oxide powder MoO3 nanoparticles MoO3 nanopowder)

FAQs of Factory molybdenum oxide powder MoO3 nanoparticles MoO3 nanopowder

Inquiry us