Overview of Factory High Purity Density Element Tantalum Metal Cube

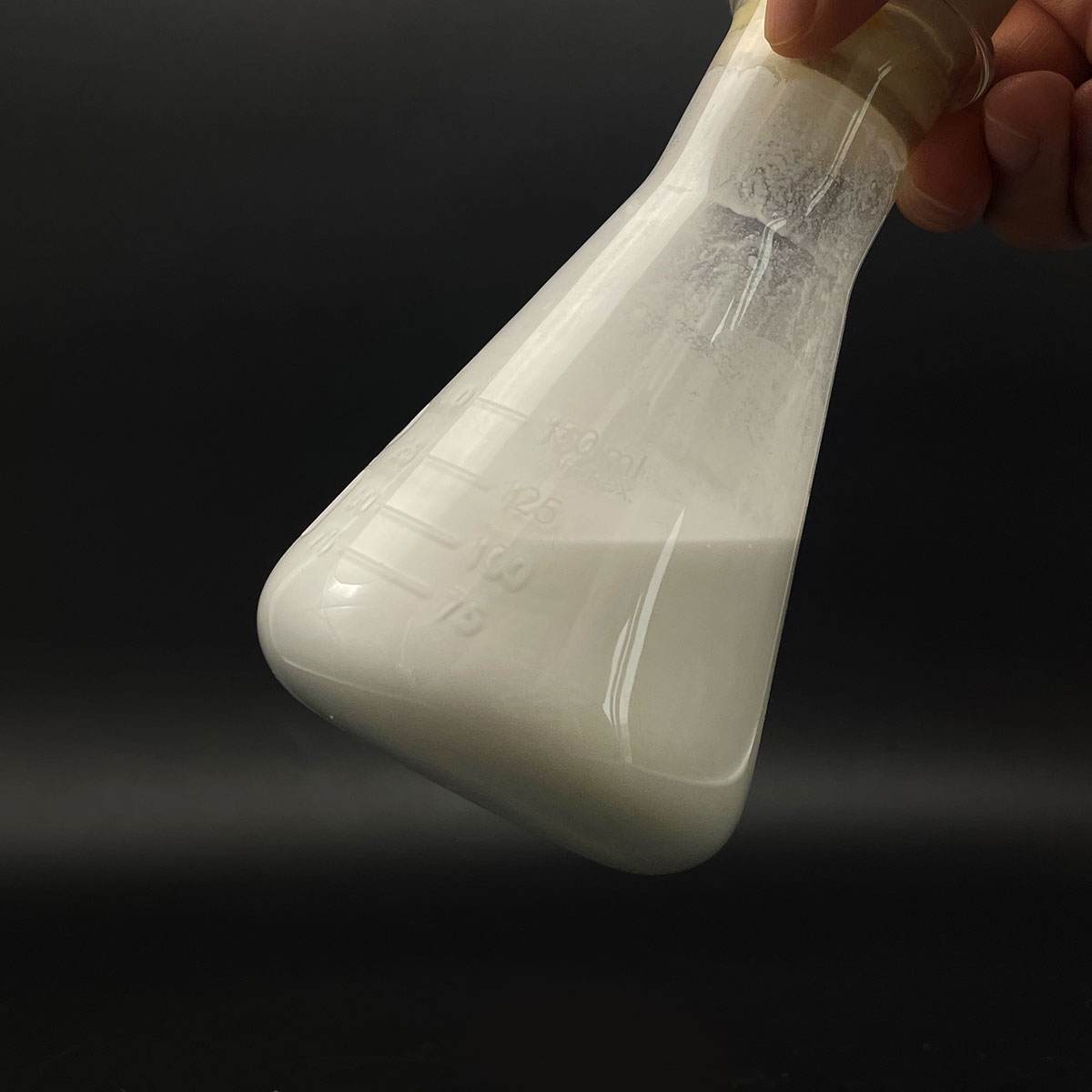

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Factory High Purity Density Element Tantalum Metal Cube

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Factory High Purity Density Element Tantalum Metal Cube)

Parameters of Factory High Purity Density Element Tantalum Metal Cube

Title: High Purity Tantalum Metal Cube: A Comprehensive Overview

Introduction

Tantalum, a chemical element with the symbol Ta and atomic number 73, is a rare, lustrous transition metal known for its exceptional strength, corrosion resistance, and high melting point. Among various tantalum products, a high purity density element tantalum metal cube stands out due to its unique combination of properties and precision manufacturing. This article delves into the key parameters and applications of such cubes without adhering to a specific format.

Elemental Properties

Tantalum exhibits an atomic weight of approximately 180.95 g/mol, making it one of the densest elements on Earth, with a density of around 16.65 g/cm³. Its high density contributes to the robustness and stability of the metal cube, ensuring that it maintains its shape under heavy loads. The metal’s inherent malleability allows for easy shaping into a cube form, while its ductility ensures minimal deformation during fabrication.

Purity Level

The high purity of tantalum metal cubes refers to their level of impurities, typically measured in parts per million (ppm). In industrial applications, a purity grade of 99.9% or higher is common, indicating that less than 1 part in 1000 of the material is impurities. This level of purity ensures the cube’s superior electrical conductivity, thermal stability, and chemical inertness, which are critical in various industries, including electronics, aerospace, and chemical processing.

Manufacturing Process

To create a high purity tantalum metal cube, the raw tantalum ore undergoes a rigorous refining process. This involves extraction from the earth, followed by purification through electrolysis, smelting, and refining steps. The end result is a pure metal ingot, which is then machined into a cube shape using advanced CNC (Computer Numerical Control) techniques. The precision of these processes ensures that the dimensions of the cube are within tight tolerances, typically ±0.01 mm or better.

Surface Finish

The surface finish of a tantalum metal cube can vary depending on the application requirements. Standard finishes include mirror-polished, electropolished, or mechanically polished surfaces. These finishes contribute to the cube’s smoothness, enhancing its appearance and reducing potential for surface contamination. The choice of finish also affects the cube’s tribological properties and compatibility with various environments.

Properties and Applications

Due to its unique combination of properties, high purity tantalum metal cubes find a wide range of applications across multiple sectors:

1. Electronics: Tantalum capacitors, often used in power supplies and high-frequency circuits, benefit from the metal’s high dielectric constant and stability at extreme temperatures.

2. Aerospace: Tantalum is lightweight yet strong, making it suitable for components in jet engines, rocket nozzles, and satellite structures where weight reduction and durability are crucial.

3. Chemical Processing: Tantalum’s corrosion resistance makes it ideal for use in harsh chemical environments, such as in chemical reactors, distillation columns, and pumps.

4. Medical Devices: Due to its biocompatibility and non-reactivity, tantalum is employed in implantable medical devices like orthopedic joints and dental implants.

5. Nuclear Industry: Tantalum’s high melting point and radiation tolerance make it suitable for use in nuclear reactors and fuel cladding.

Conclusion

In conclusion, a high purity tantalum metal cube is a technologically advanced component with exceptional properties. Its density, purity, and precision manufacturing ensure optimal performance in diverse applications, ranging from electronics to aerospace. As technology continues to advance, the demand for such high-quality tantalum cubes will likely grow, highlighting the importance of understanding their unique characteristics and capabilities.

(Factory High Purity Density Element Tantalum Metal Cube)

FAQs of Factory High Purity Density Element Tantalum Metal Cube

Inquiry us