Overview of Emeraling chromium oxide green Powder for enamel coating

Telluride and selenide compounds play a significant role in the field of semiconductors, particularly in the development of advanced electronic and optoelectronic devices. These materials belong to the chalcogenide family, characterized by their ability to form compounds with elements from groups IV-VI in the periodic table.

Tellurides: Compounds containing tellurium (Te) as the chalcogen. Examples include cadmium telluride (CdTe), mercury telluride (HgTe), and zinc telluride (ZnTe). These materials have found applications in solar cells, infrared detectors, and high-speed electronics due to their tunable bandgap, high electron mobility, and good thermal stability.

Selenides: Similar to tellurides, but with selenium (Se) replacing tellurium. Notable examples are cadmium selenide (CdSe), gallium selenide (GaSe), and zinc selenide (ZnSe). Selenide compounds are widely used in light-emitting diodes (LEDs), laser diodes, and solar cells due to their direct bandgap properties and efficient light absorption/emission capabilities.

Feature of Emeraling chromium oxide green Powder for enamel coating

Direct Bandgap: Many telluride and selenide semiconductors have direct bandgaps, which facilitate efficient light emission and absorption processes. This makes them suitable for optoelectronic applications such as LEDs and lasers.

Tunable Bandgap: The bandgap of these materials can be adjusted by alloying or altering the composition (e.g., CdSe to CdTe), enabling customization for specific device requirements across a wide spectrum of wavelengths.

High Electron Mobility: Materials like HgCdTe exhibit high electron mobility, which is crucial for high-speed electronic devices and low-noise detector applications.

Thermal Stability: Some tellurides and selenides, like ZnTe and ZnSe, demonstrate good thermal stability, making them suitable for high-temperature operation and processing.

Non-Toxic Alternatives: With increasing environmental concerns, there’s a push towards exploring less toxic alternatives to commonly used semiconductors. For instance, Cd-based tellurides and selenides are being replaced or combined with less toxic elements like Mg or Mn in some applications.

(Emeraling chromium oxide green Powder for enamel coating)

Parameters of Emeraling chromium oxide green Powder for enamel coating

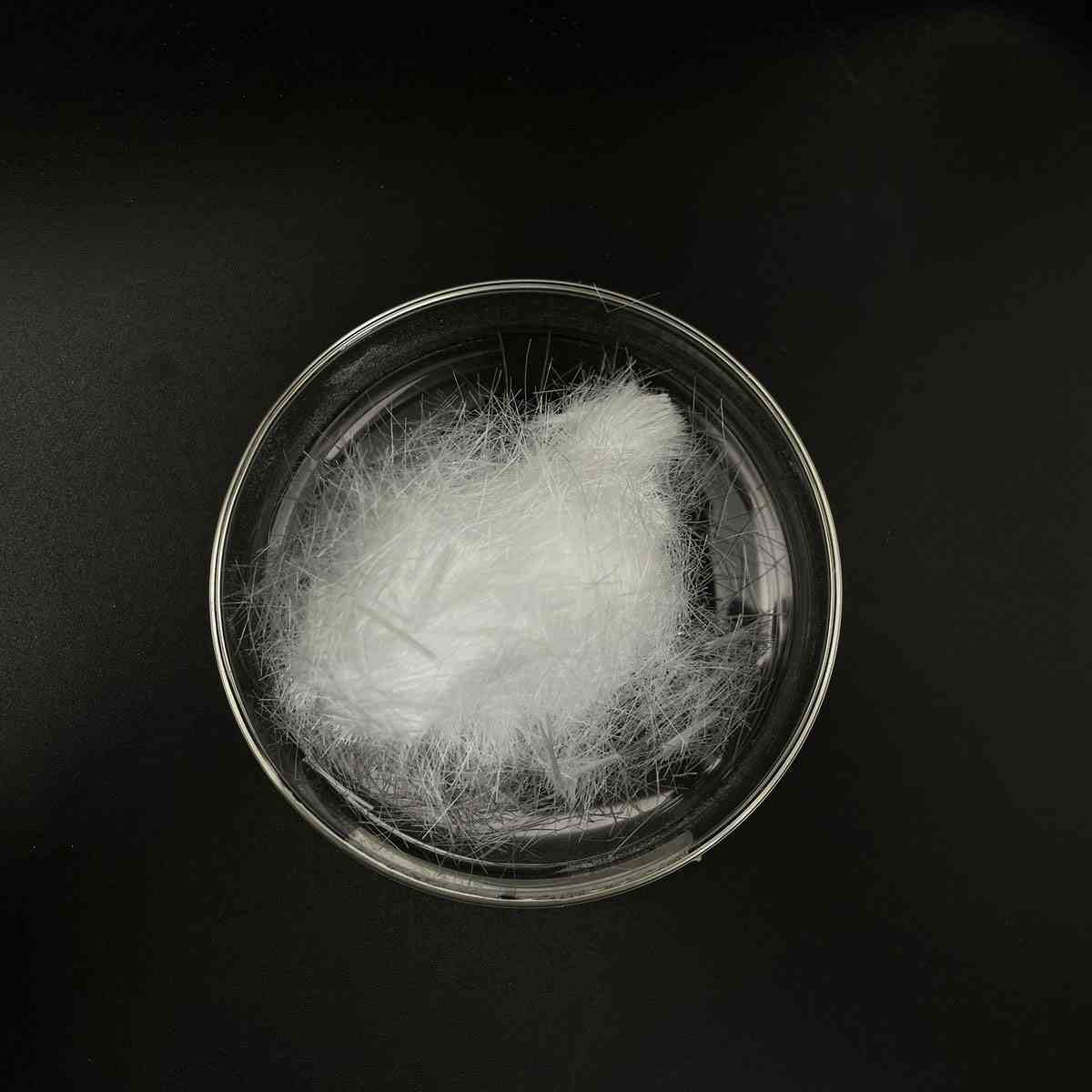

Emerald Chromium Oxide Green Powder, often referred to as ECOG or Emerald Green Chromate, is a pigment commonly used in the enamel coating industry due to its vibrant and captivating color. This unique compound consists of chromium(III) oxide (Cr2O3) mixed with various binders to create a fine, powdery form that can be easily incorporated into various enamel formulations.

The primary characteristic of Emerald Chromium Oxide Green Powder is its rich, deep emerald green hue, which imparts a luxurious and elegant appearance to the final product. The color intensity can vary depending on the specific formulation, but it generally ranges from a vivid forest green to a more muted olive tone. This color stability makes it suitable for a wide range of applications, including automotive, architectural coatings, and even ceramic and glass enamels.

In terms of technical parameters, ECOG powder has a particle size distribution that is carefully controlled to ensure consistent dispersion and adhesion in the coating process. The average particle size is typically between 50 and 200 microns, although some grades may have a narrower range for improved flow properties and surface coverage. The particle shape is usually irregular, providing better mechanical stability during handling and application.

The pigment’s lightfastness is another crucial factor, as it determines how well the color remains intact under exposure to UV radiation and environmental conditions. Emerald Chromium Oxide Green Powder exhibits good lightfastness, ensuring that the vibrant green will not fade over time, which is essential for long-lasting and aesthetically pleasing coatings.

The compatibility of ECOG with other ingredients in the enamel formulation is another aspect to consider. It is compatible with various binders, such as acrylics, silicates, and polyurethanes, allowing for a wide range of formulations to achieve the desired finish and performance characteristics. However, it is essential to conduct compatibility tests to confirm compatibility with specific resin systems before incorporating it into a new product.

In terms of performance, ECOG powder contributes to the overall durability and resistance of the coated surface. It enhances the adhesion between the enamel layer and the substrate, resulting in a strong, scratch-resistant finish. Additionally, it can provide a hard, glossy sheen when heat cured, making it popular in applications like automotive paint and industrial coatings.

Safety precautions should always be observed when handling Emerald Chromium Oxide Green Powder, as it may contain small amounts of chromium, which can be a health concern if not handled properly. Proper personal protective equipment (PPE), such as gloves and respiratory protection, should be worn during handling, and storage should be in a well-ventilated area away from direct sunlight to prevent degradation.

In summary, Emerald Chromium Oxide Green Powder is a high-quality pigment that adds a striking emerald green hue to enamel coatings. Its technical properties, including particle size, lightfastness, and compatibility with various resins, make it a versatile choice for various industries. While handling and safety considerations must be taken, when used correctly, this pigment can significantly enhance the visual appeal and performance of finished products.

(Emeraling chromium oxide green Powder for enamel coating)

FAQ of Semiconductor Materials

Inquiry us