Overview of Customized 99.95% spherical carbide tungsten powder for industrial metallurgical

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Customized 99.95% spherical carbide tungsten powder for industrial metallurgical

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

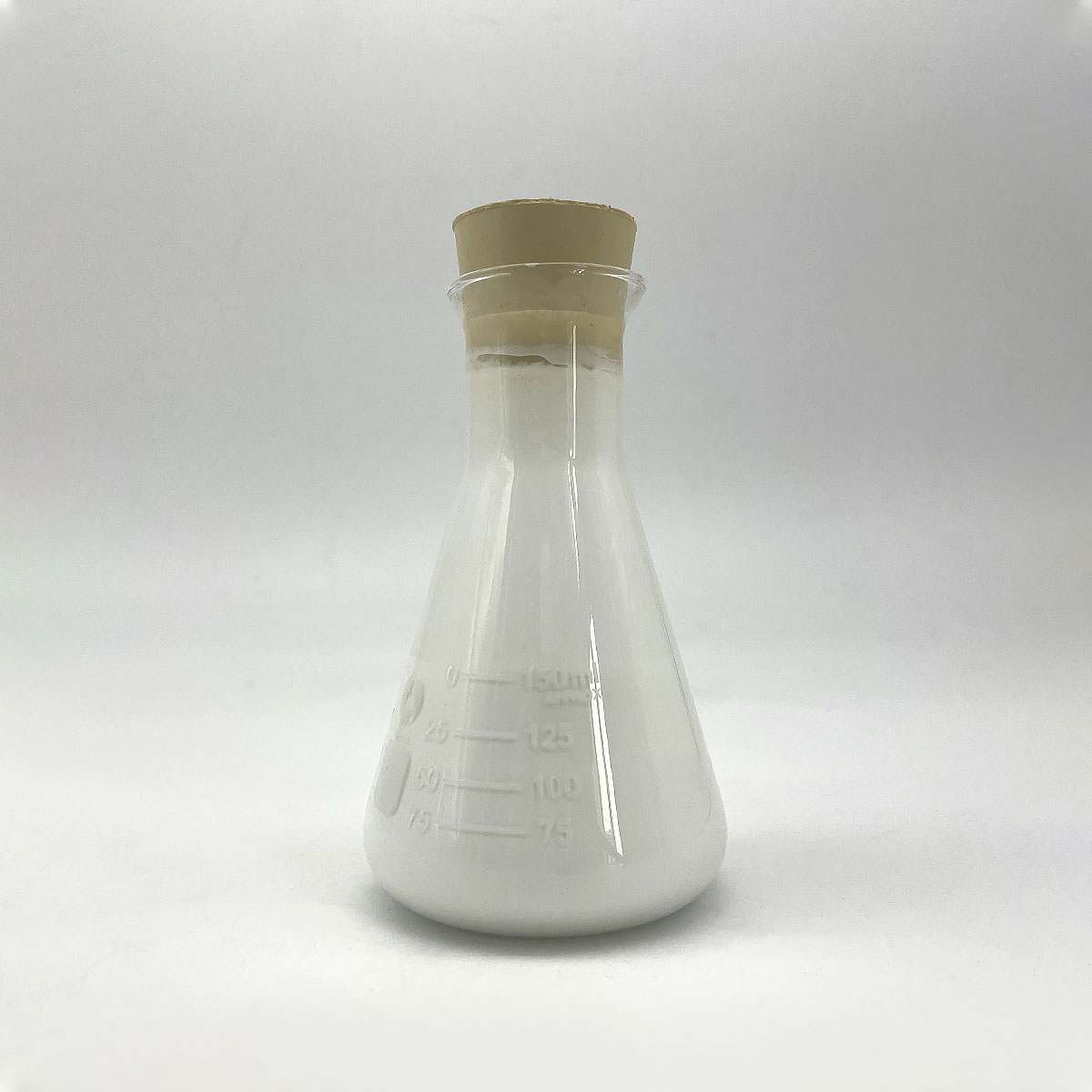

(Customized 99.95% spherical carbide tungsten powder for industrial metallurgical)

Parameters of Customized 99.95% spherical carbide tungsten powder for industrial metallurgical

Title: Advanced Customized Spherical Carbide Tungsten Powder for Industrial Metallurgy: A High-Purity Solution

Introduction:

In the realm of modern industrial metallurgy, the quest for high-performance materials has led to the development of specialized powders that offer exceptional properties. One such compound is our state-of-the-art, 99.95% pure spherical carbide tungsten powder. This unique material stands out due to its unparalleled purity, superior sphericity, and tailored characteristics designed to enhance efficiency in various applications.

Properties:

1. Purity: Our spherical carbide tungsten powder boasts an impressive 99.95% purity, ensuring a minimal impurity content that translates into enhanced mechanical strength, wear resistance, and overall performance in demanding industrial processes.

2. Sphericity: The powders are meticulously processed to achieve near-perfect spherical shapes, which promote uniform mixing and improve flowability during compaction or sintering. This feature contributes to reduced porosity and improved density, resulting in stronger and more consistent end products.

3. Hardness: Derived from the hardest naturally occurring element, tungsten carbide, this powder offers exceptional hardness and thermal stability. It is ideal for applications requiring extreme hardness, such as cutting tools, wear-resistant coatings, and components.

4. Customization: Tailored to meet specific industry requirements, our tungsten carbide powder can be engineered with varying particle sizes, shapes, and surface treatments to optimize performance in diverse metallurgical processes. This versatility allows for customization to suit different melting and forming techniques.

5. Enhanced Reactivity: The spherical shape promotes better reactivity when combined with binders or other materials, leading to efficient consolidation and bonding during the manufacturing process. This results in a strong, homogeneous structure that withstands harsh operating conditions.

Applications:

The customized spherical carbide tungsten powder finds extensive use across various sectors, including:

– Tool and Manufacturing: As a key component in cemented carbide, it is employed in high-speed cutting tools, drill bits, and milling inserts for precision engineering.

– Mining and Metallurgy: Its wear-resistant properties make it ideal for ball mills, crushers, and wear-resistant linings in the mining and processing of hard materials.

– Wear Protection: Applied in the form of coatings on machinery parts, bearings, and gears, it extends their operational life and reduces maintenance costs.

– Aerospace and Defense: Used in the production of wear-resistant components and coatings for jet engines, where high-temperature and abrasive environments prevail.

Conclusion:

Our 99.95% spherical carbide tungsten powder represents a significant advancement in industrial metallurgy, offering unparalleled purity, superior performance, and customization capabilities. Its exceptional properties make it an indispensable choice for industries seeking to optimize efficiency, productivity, and product durability. With ongoing research and development, we continue to push the boundaries of material science, enabling new frontiers in advanced manufacturing and engineering.

(Customized 99.95% spherical carbide tungsten powder for industrial metallurgical)

FAQs of Customized 99.95% spherical carbide tungsten powder for industrial metallurgical

Inquiry us