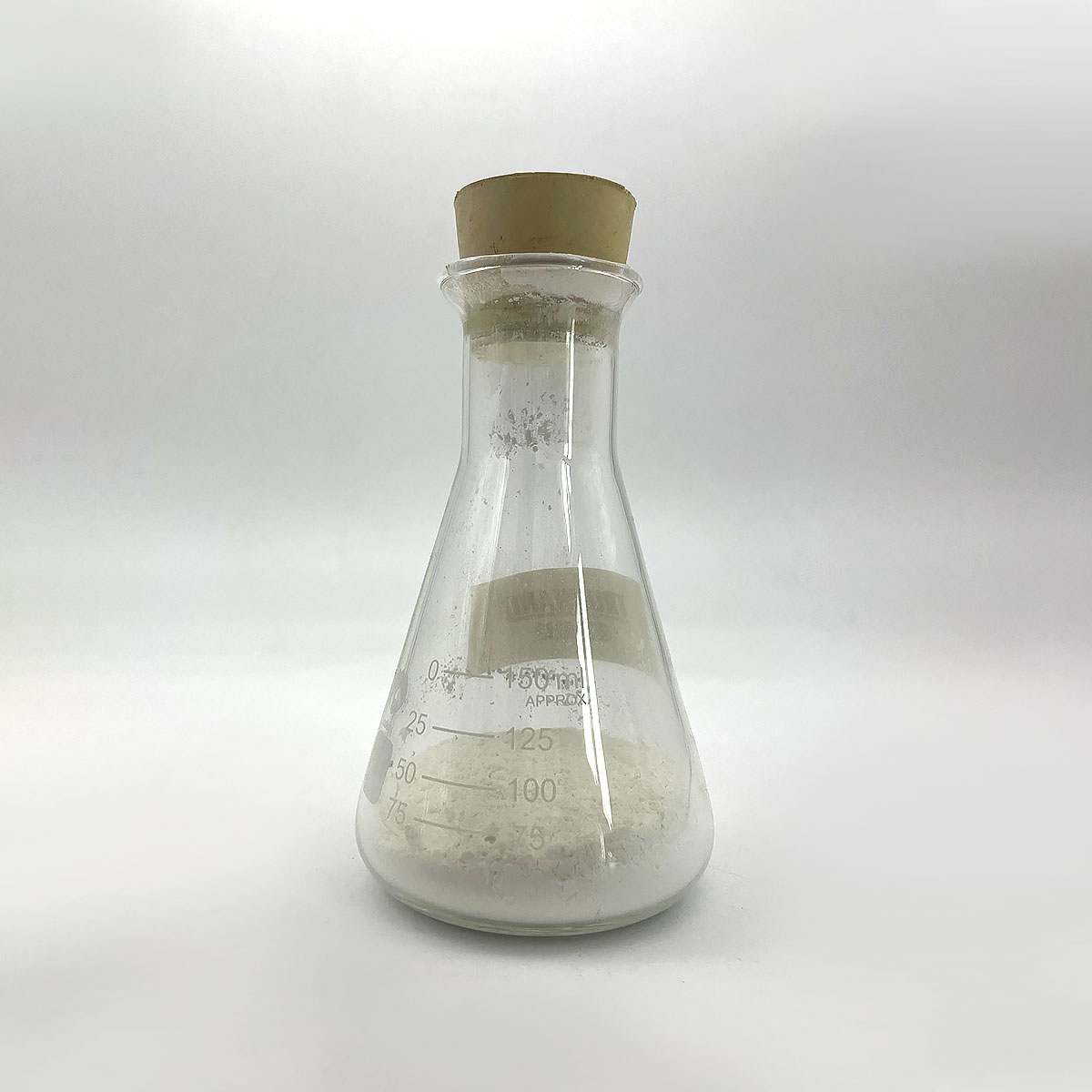

Overview of Cavity Bar Plunger (Semiconductor Mold) made from ultra-fine tungsten carbide powder barrel assy and plunger carbide plunger

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Cavity Bar Plunger (Semiconductor Mold) made from ultra-fine tungsten carbide powder barrel assy and plunger carbide plunger

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Cavity Bar Plunger (Semiconductor Mold) made from ultra-fine tungsten carbide powder barrel assy and plunger carbide plunger)

Parameters of Cavity Bar Plunger (Semiconductor Mold) made from ultra-fine tungsten carbide powder barrel assy and plunger carbide plunger

The Cavity Bar Plunger, also known as a Semiconductor Mold in the field of precision engineering, is a critical component designed for high-precision applications, particularly within the semiconductor industry. This advanced tool is fabricated using state-of-the-art technology that involves the manufacturing of an ultra-fine tungsten carbide powder barrel assembly and a plunger made from the same durable material.

Tungsten carbide, a renowned superalloy, is chosen for its exceptional hardness, wear resistance, and thermal stability. The material’s microstructure, achieved through the use of fine tungsten carbide powder, ensures an unparalleled surface finish and dimensional accuracy. The powder metallurgy process employed in its production results in a homogeneous structure with minimal porosity, making it ideal for demanding environments where reliability and longevity are paramount.

The barrel assembly, which constitutes the base of the cavity bar plunger, is meticulously crafted to provide a consistent and stable cavity formation. Its precise geometry allows for efficient mold release, ensuring smooth and defect-free molding of semiconductor wafers. The intricate design takes into consideration factors such as thermal expansion, stress distribution, and cycle life, all of which contribute to the overall performance and efficiency of the mold.

The plunger, on the other hand, serves as the moving element responsible for creating the desired shape in the molten material. It undergoes rigorous precision grinding and honing processes to achieve a mirror-like finish, minimizing surface roughness and ensuring minimal friction during operation. This results in improved part quality and reduced waste due to surface defects.

The absence of any specific format indicates that the Cavity Bar Plunger can be customized to cater to various industry-specific requirements. Its versatility allows it to be adapted for different semiconductor processes, including photolithography, thin film deposition, and etching. The ability to modify the dimensions, shapes, and depths of the mold cavities makes it a versatile tool that can accommodate a wide range of product geometries.

In conclusion, the Cavity Bar Plunger, a semiconductor mold made from ultra-fine tungsten carbide powder, represents the pinnacle of precision engineering. Its combination of advanced materials, meticulous manufacturing processes, and customizable design make it an indispensable tool in the semiconductor industry. Its superior performance, durability, and adaptability ensure consistently high-quality products and streamline the manufacturing process, ultimately contributing to the success of modern semiconductor technologies.

(Cavity Bar Plunger (Semiconductor Mold) made from ultra-fine tungsten carbide powder barrel assy and plunger carbide plunger)

FAQs of Cavity Bar Plunger (Semiconductor Mold) made from ultra-fine tungsten carbide powder barrel assy and plunger carbide plunger

Inquiry us