Overview of Casting Reduce Melting Temperature Titanium Additives For Aluminum Casting

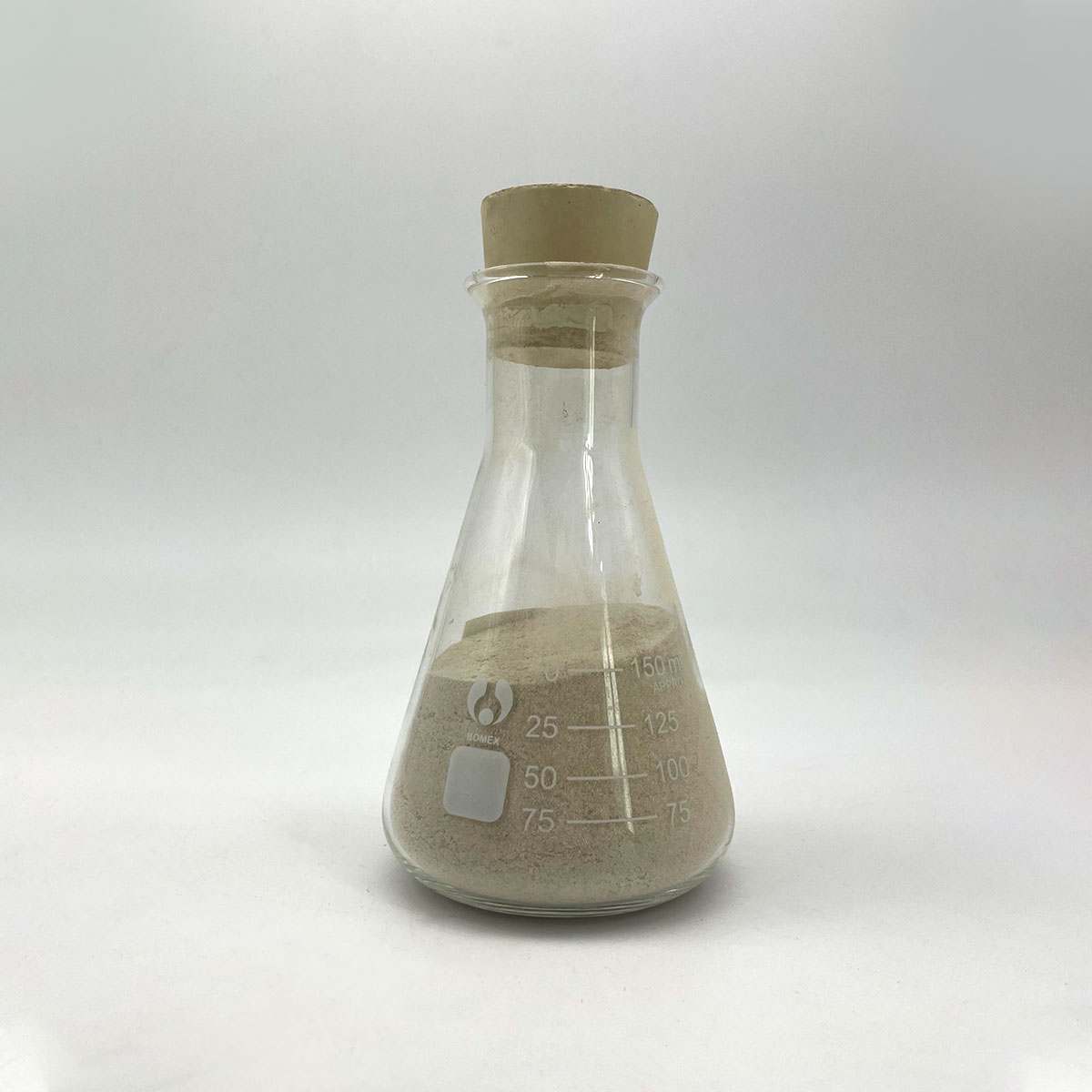

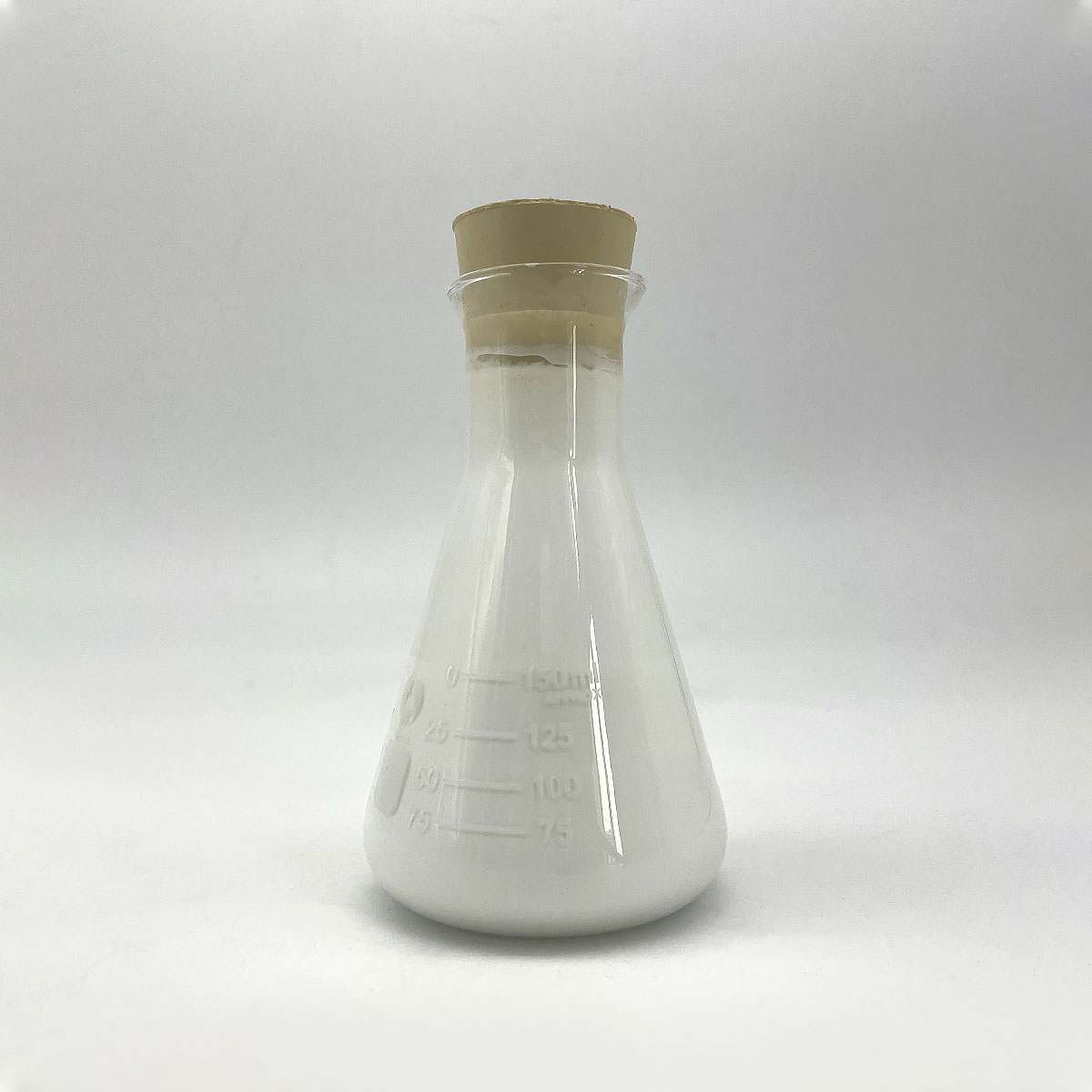

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Casting Reduce Melting Temperature Titanium Additives For Aluminum Casting

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Casting Reduce Melting Temperature Titanium Additives For Aluminum Casting)

Parameters of Casting Reduce Melting Temperature Titanium Additives For Aluminum Casting

Title: Optimizing Titanium Additives for Enhanced Melting Point in Aluminum Casting: A Comprehensive Analysis

Introduction

The aluminum casting industry is constantly seeking innovative methods to improve the quality, strength, and efficiency of their processes. One promising approach involves incorporating titanium additives into the aluminum alloy mix, as titanium can significantly enhance the melting temperature and mechanical properties of the final product. This article delves into the science behind these additives, their impact on the casting process, and the optimal parameters for achieving a reduced melting temperature without compromising the integrity of the aluminum casting.

Titanium in Aluminum Alloys

Titanium, known for its high strength-to-weight ratio and excellent corrosion resistance, has been successfully integrated into aluminum alloys to create a range of composite materials. When added to aluminum, titanium acts as a solid solution, increasing the alloy’s hardness, thermal stability, and creep resistance. It also improves the microstructure by refining grain size, which can lead to better mechanical properties and enhanced casting performance.

Melting Temperature Considerations

The addition of titanium to aluminum alloys typically results in a slight increase in the melting point. However, this increase is not always detrimental, as it can provide benefits such as improved hot tearing resistance and better control during the casting process. The key lies in finding the right balance between the titanium content and the casting parameters to maintain a manageable melting temperature that ensures efficient casting without excessive heat loss or damage.

Optimization Parameters

1. Additive Concentration: The amount of titanium in the aluminum alloy significantly influences the melting temperature. A lower concentration may result in a more manageable melting point, but the improvement in properties might be limited. Higher concentrations can offer better performance but may require adjustments in casting techniques and equipment to handle the increased heat.

2. Mixing Techniques: Proper mixing of titanium with aluminum is crucial to ensure homogeneity. Mechanical alloying, vacuum melting, or arc melting can be employed, depending on the desired purity and particle size distribution. Efficient mixing will minimize phase separation and ensure a uniform melting temperature throughout the casting process.

3. Cooling Rates: Faster cooling rates can help mitigate the rise in melting temperature due to titanium addition. By controlling the cooling speed, the casting can maintain its integrity while benefiting from the improved properties provided by titanium. Slower cooling can lead to grain growth, affecting the final mechanical properties.

4. Casting Process Parameters: Adjusting parameters like pouring temperature, mold design, and pouring technique can help manage the increased melting temperature. Using insulation and well-insulated molds, along with controlled pouring conditions, can minimize heat loss and maintain a consistent casting process.

5. Post-Casting Heat Treatment: Depending on the specific application, post-casting heat treatments can help optimize the microstructure and mechanical properties of the titanium-aluminum alloy. Annealing or tempering can help refine grains and improve ductility without compromising the reduced melting temperature.

Conclusion

Incorporating titanium additives into aluminum casting offers a promising avenue for enhancing the material’s performance. By carefully selecting the appropriate additive concentration, mixing techniques, and adjusting casting parameters, it is possible to achieve a reduced melting temperature without sacrificing quality. Continuous research and experimentation in this field will pave the way for more advanced aluminum alloys tailored to specific industrial needs, driving innovation and efficiency in the casting industry.

(Casting Reduce Melting Temperature Titanium Additives For Aluminum Casting)

FAQs of Casting Reduce Melting Temperature Titanium Additives For Aluminum Casting

Inquiry us