Overview of cas no 12069-94-2 NbC powder niobium carbide powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of cas no 12069-94-2 NbC powder niobium carbide powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

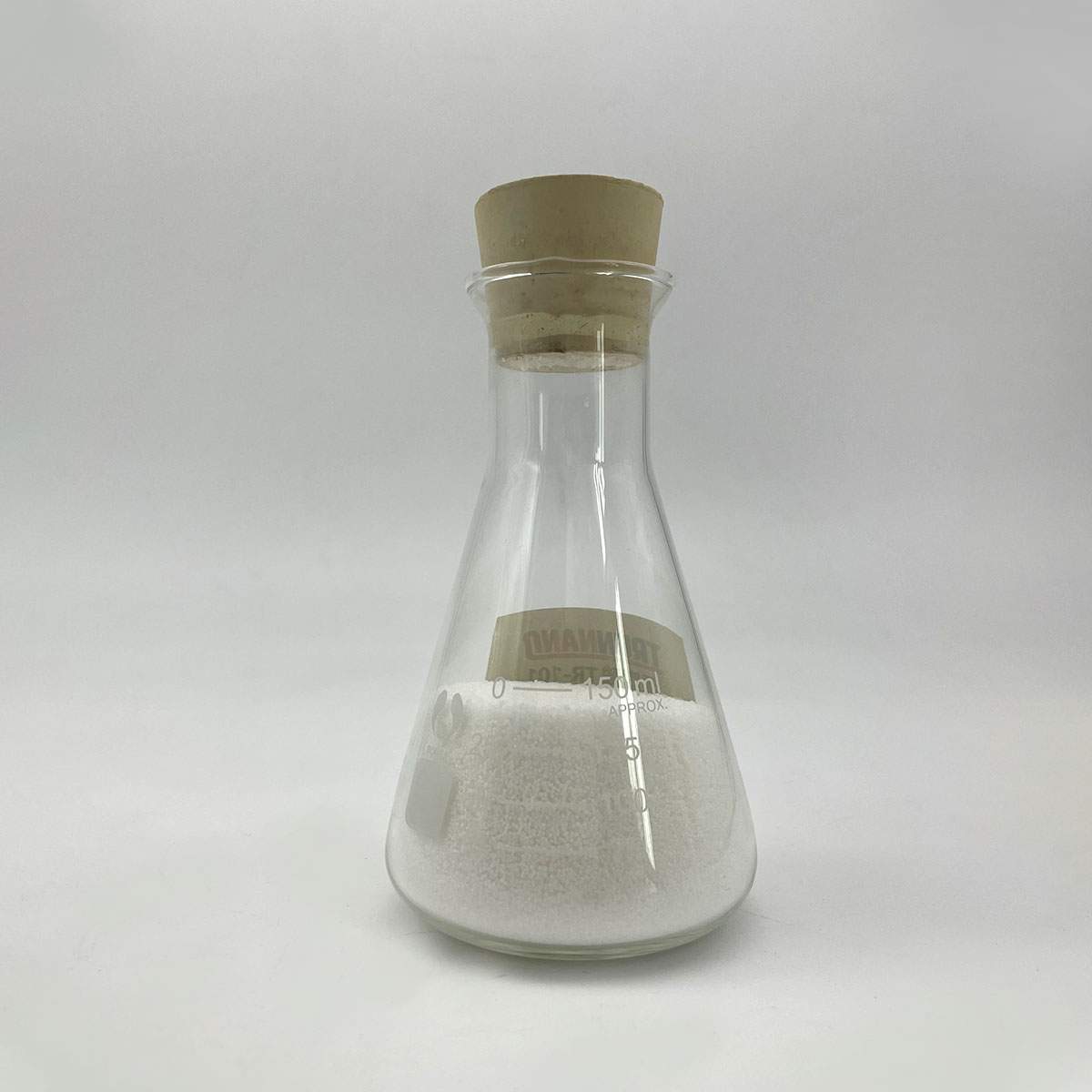

(cas no 12069-94-2 NbC powder niobium carbide powder)

Parameters of cas no 12069-94-2 NbC powder niobium carbide powder

Cas No. 12069-94-2 refers to the Chemical Abstracts Service (CAS) registry number, which is a unique identifier assigned to niobium carbide (NbC) powder. This specific compound is a binary compound formed by the combination of niobium (Nb), a transition metal from Group 5 of the periodic table, and carbon (C), an element from Group 14. Niobium carbide is known for its exceptional properties that make it valuable in various industrial applications.

The powder form of NbC is characterized by its high purity, fine grain size, and high density, typically in the range of 3.2 to 3.4 g/cm³. The particle size distribution is crucial, as it affects the material’s mechanical properties, such as hardness, wear resistance, and thermal conductivity. A well-dispersed powder with uniform particle size ensures better performance in composite materials and coatings.

In terms of crystal structure, niobium carbide exists primarily in the α-NbC phase, which has a hexagonal close-packed (hcp) arrangement of niobium atoms with carbon intercalated between them. This structure gives rise to strong metallic bonds, making NbC a hard and refractory material with a Mohs hardness of around 8.5 on the scale of 10.

One of the key features of NbC is its outstanding thermal stability and resistance to oxidation. It maintains its integrity at elevated temperatures, making it suitable for applications in high-temperature environments, such as gas turbines, aerospace, and nuclear industries. The high thermal conductivity, around 200 W/m·K, also contributes to efficient heat dissipation.

Furthermore, niobium carbide exhibits excellent wear resistance and chemical inertness, which are essential for applications requiring long-term durability and minimal material degradation. It is often used as a coating material for cutting tools, wear-resistant parts, and as a catalyst support in chemical processes.

In addition to these technical characteristics, the synthesis methods for obtaining Cas No. 12069-94-2 NbC powder can vary. Common techniques include mechanical alloying, sublimation, or carbothermal reduction of niobium metal with carbon sources. Each method may influence the final product’s properties, such as particle size, morphology, and purity.

In conclusion, Cas No. 12069-94-2 NbC powder is a high-performance material with a hexagonal close-packed structure that exhibits exceptional thermal stability, wear resistance, and chemical inertness. Its unique combination of properties makes it suitable for a wide range of applications, including aerospace, automotive, and industrial manufacturing, where high-performance materials are required under demanding conditions. The powder’s fine grain size and uniformity ensure consistent performance when incorporated into composite materials or used as a coating.

(cas no 12069-94-2 NbC powder niobium carbide powder)

FAQs of cas no 12069-94-2 NbC powder niobium carbide powder

Inquiry us