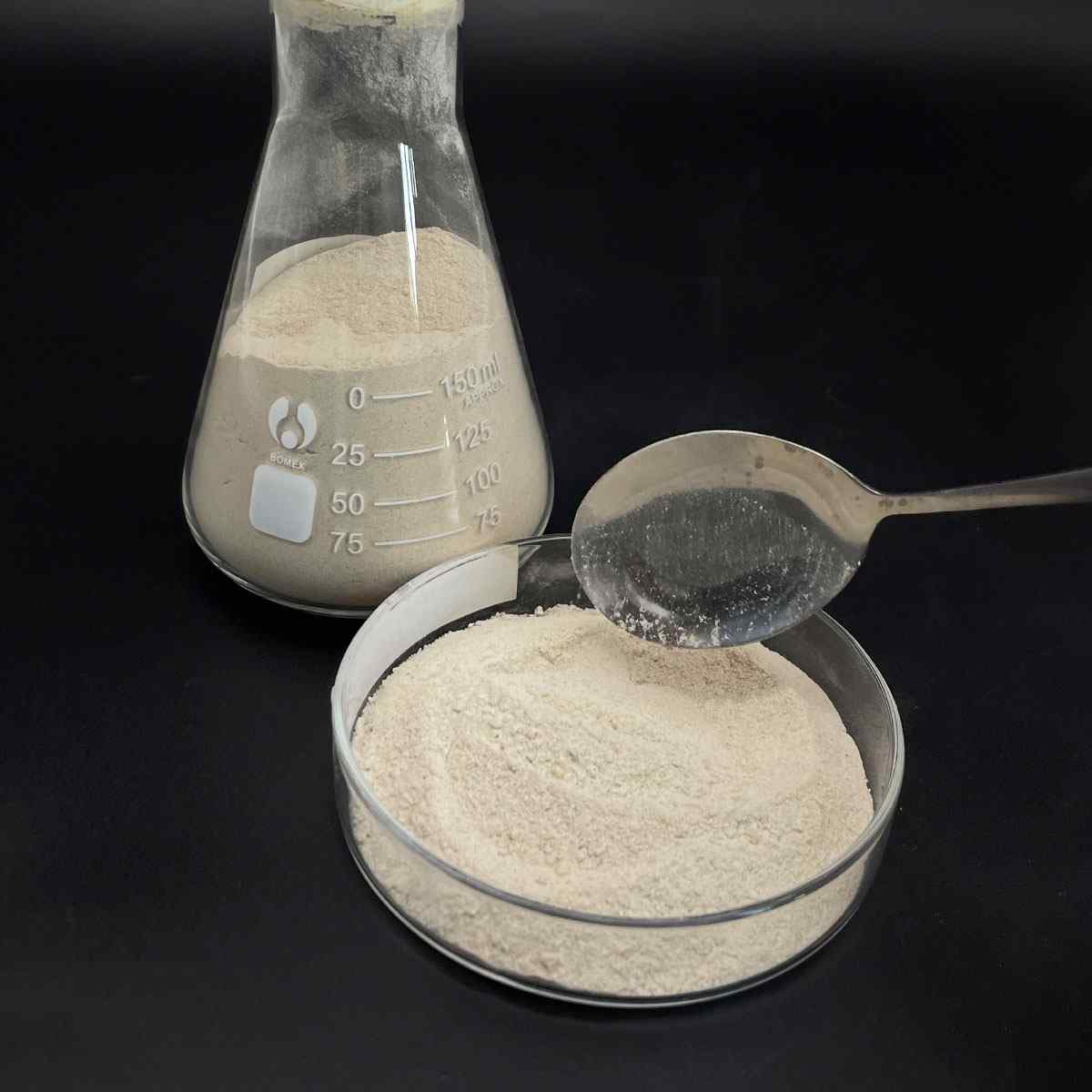

Overview of Buy High Purity cas 18868-43-4 MoO2 Molybdenum dioxide Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Buy High Purity cas 18868-43-4 MoO2 Molybdenum dioxide Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Buy High Purity cas 18868-43-4 MoO2 Molybdenum dioxide Powder)

Parameters of Buy High Purity cas 18868-43-4 MoO2 Molybdenum dioxide Powder

Title: Procuring High Purity CAS 18868-43-4 MoO2: A Comprehensive Guide to Molybdenum Dioxide Powder

Introduction

Molybdenum dioxide (MoO2), with the chemical formula CAS number 18868-43-4, is a versatile inorganic compound that finds extensive applications in various industries due to its unique properties such as high thermal stability, electrical conductivity, and catalytic activity. This particular article aims to provide an in-depth understanding of purchasing high purity MoO2 powder, focusing on key parameters and considerations for a successful acquisition.

Purity

The purity of MoO2 is a critical factor when selecting the product, as it directly affects its performance and reliability. High purity MoO2, typically above 99.9%, ensures minimal impurities, which can lead to enhanced efficiency and reduced contamination in end-use applications. It’s essential to verify the purity certificate provided by the supplier to ensure the quality meets your requirements.

Particle Size Distribution

Particle size distribution (PSD) is another crucial parameter to consider, as it influences the material’s reactivity, surface area, and overall handling characteristics. For optimal results, choose a MoO2 powder with a narrow PSD range, ensuring consistent particle sizes for uniform dispersion and improved performance in your processes. Commonly available particle sizes include micron and sub-micron grades, so make sure to specify your desired range.

Bulk Density

Bulk density refers to the mass per unit volume of the powder. A higher bulk density means less volume for a given weight, which can result in cost savings during transportation and storage. However, it’s essential to balance this with the ease of handling and processing. Suppliers should provide information on the specific bulk density of their product to help you make an informed decision.

Particle Shape and Surface Finish

The shape and surface finish of MoO2 particles play a role in determining the powder’s reactivity and mixing properties. A well-crystalline structure with smooth surfaces generally enhances the contact between the powder and other materials, improving the overall efficiency of reactions. Ensure the supplier provides details about the particle shape, such as spherical or flaky, and the surface finish, like milled or ground.

Grade and Classification

Molybdenum dioxide can be found in different grades, including industrial, technical, and electronic-grade. Electronic-grade MoO2 is characterized by its ultra-high purity and low impurities, making it suitable for advanced electronic applications. Technical-grade, while slightly less pure, offers better cost-effectiveness for general industrial uses. Ensure you select the appropriate grade based on your specific application requirements.

Environmental Impact and Safety

When sourcing MoO2 powder, it’s important to consider the supplier’s commitment to environmental responsibility and safety measures. Look for suppliers who adhere to strict quality control standards and have a proven track record of responsible sourcing. Additionally, ensure the product is stored and handled safely, as molybdenum dioxide can be hazardous if not managed correctly.

Conclusion

In summary, purchasing high purity CAS 18868-43-4 MoO2 powder involves careful consideration of factors such as purity, particle size distribution, bulk density, particle shape, grade, and environmental impact. By evaluating these parameters, you can ensure that you select the most suitable MoO2 powder for your specific needs, optimizing performance and minimizing potential risks. Always engage with reputable suppliers who can provide detailed product information and reliable support throughout the procurement process.

(Buy High Purity cas 18868-43-4 MoO2 Molybdenum dioxide Powder)

FAQs of Buy High Purity cas 18868-43-4 MoO2 Molybdenum dioxide Powder

Inquiry us