Overview of Best ing Metal Cubes 10mm Hafnium Tantalum Tungsten Erbium Rhenium Samarium Gadolinium Titanium Vanadium Density Cube 10mm

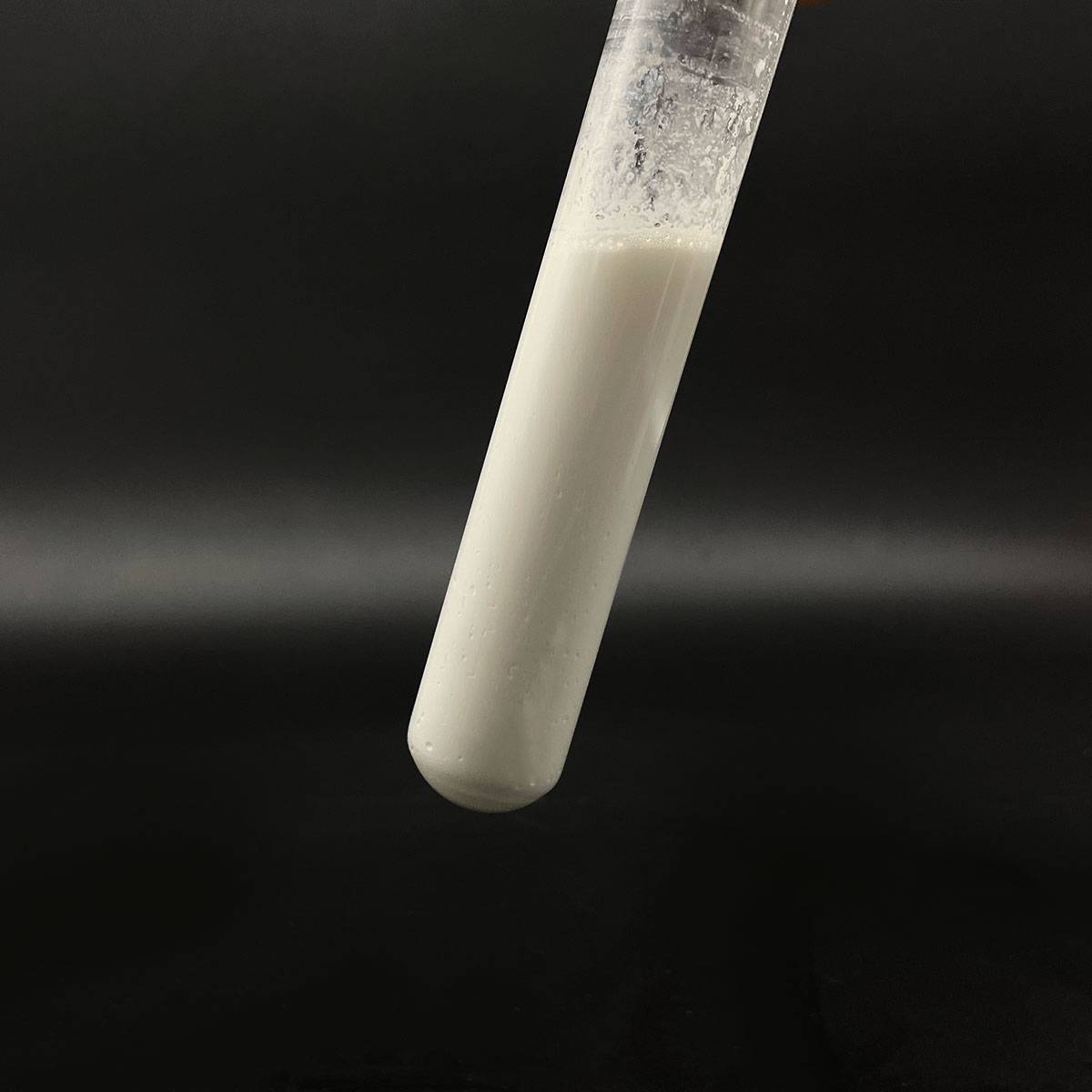

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Best ing Metal Cubes 10mm Hafnium Tantalum Tungsten Erbium Rhenium Samarium Gadolinium Titanium Vanadium Density Cube 10mm

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Best ing Metal Cubes 10mm Hafnium Tantalum Tungsten Erbium Rhenium Samarium Gadolinium Titanium Vanadium Density Cube 10mm)

Parameters of Best ing Metal Cubes 10mm Hafnium Tantalum Tungsten Erbium Rhenium Samarium Gadolinium Titanium Vanadium Density Cube 10mm

Metal cubes, particularly those with a size of 10mm, are versatile components in various industries, from scientific research to engineering applications. Among the numerous options available, four metals stand out due to their unique properties: Hafnium, Tantalum, Tungsten, and the rare earth elements Erbium, Rhenium, Samarium, Gadolinium, as well as Titanium and Vanadium. Let’s delve into these materials and their characteristics.

Hafnium, a lustrous metal, is known for its high melting point (2527°C) and excellent corrosion resistance. It is often used in aerospace and nuclear industries for lightweight yet strong components, such as engine parts and fuel cladding. Its density of around 18.95 g/cm³ makes it ideal for situations where weight reduction is crucial without compromising strength.

Tantalum, another heavy metal, boasts a remarkable combination of strength and durability. With a melting point of 3017°C, it is corrosion-resistant and resistant to both heat and wear. Its density of approximately 16.66 g/cm³ makes it suitable for applications like medical implants, chemical processing equipment, and high-temperature electronics.

Tungsten, known for its exceptional density (19.25 g/cm³), is the densest naturally occurring element on Earth. This property gives it immense strength and rigidity, making it popular in areas like bullet tips, filaments for light bulbs, and cutting tools. Tungsten carbide, a compound of tungsten and carbon, is even harder than steel.

Erbium, Rhenium, Samarium, and Gadolinium are rare earth elements that exhibit unique magnetic properties. These elements, when combined, create alloys with high magnetic susceptibilities, making them essential in advanced technologies like magnets, electronic devices, and data storage systems. Their densities vary slightly but are generally within the range of 7.2 to 11.5 g/cm³.

Titanium, with a density of about 4.54 g/cm³, is lightweight yet incredibly strong, earning it the nickname “the metal of the future.” It finds applications in aerospace, biomedical implants, and marine structures due to its corrosion resistance and biocompatibility.

Vanadium, with a density of 6.06 g/cm³, is known for its high hardness and good mechanical properties. It is commonly used in steel alloys to improve strength and toughness, as well as in catalysts and superalloys for high-temperature applications.

In summary, 10mm metal cubes made from Hafnium, Tantalum, Tungsten, and rare earth elements like Erbium, Rhenium, Samarium, Gadolinium, as well as Titanium and Vanadium, offer distinct advantages in terms of density, strength, corrosion resistance, and unique properties. Each material has its specific niche in various industries, making them indispensable components for modern technology and engineering needs. The choice of material depends on the specific application’s requirements, performance expectations, and budget constraints.

(Best ing Metal Cubes 10mm Hafnium Tantalum Tungsten Erbium Rhenium Samarium Gadolinium Titanium Vanadium Density Cube 10mm)

FAQs of Best ing Metal Cubes 10mm Hafnium Tantalum Tungsten Erbium Rhenium Samarium Gadolinium Titanium Vanadium Density Cube 10mm

Inquiry us