Overview of Best 99.9% Min Tantalum Oxide best Ta2O5

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Best 99.9% Min Tantalum Oxide best Ta2O5

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

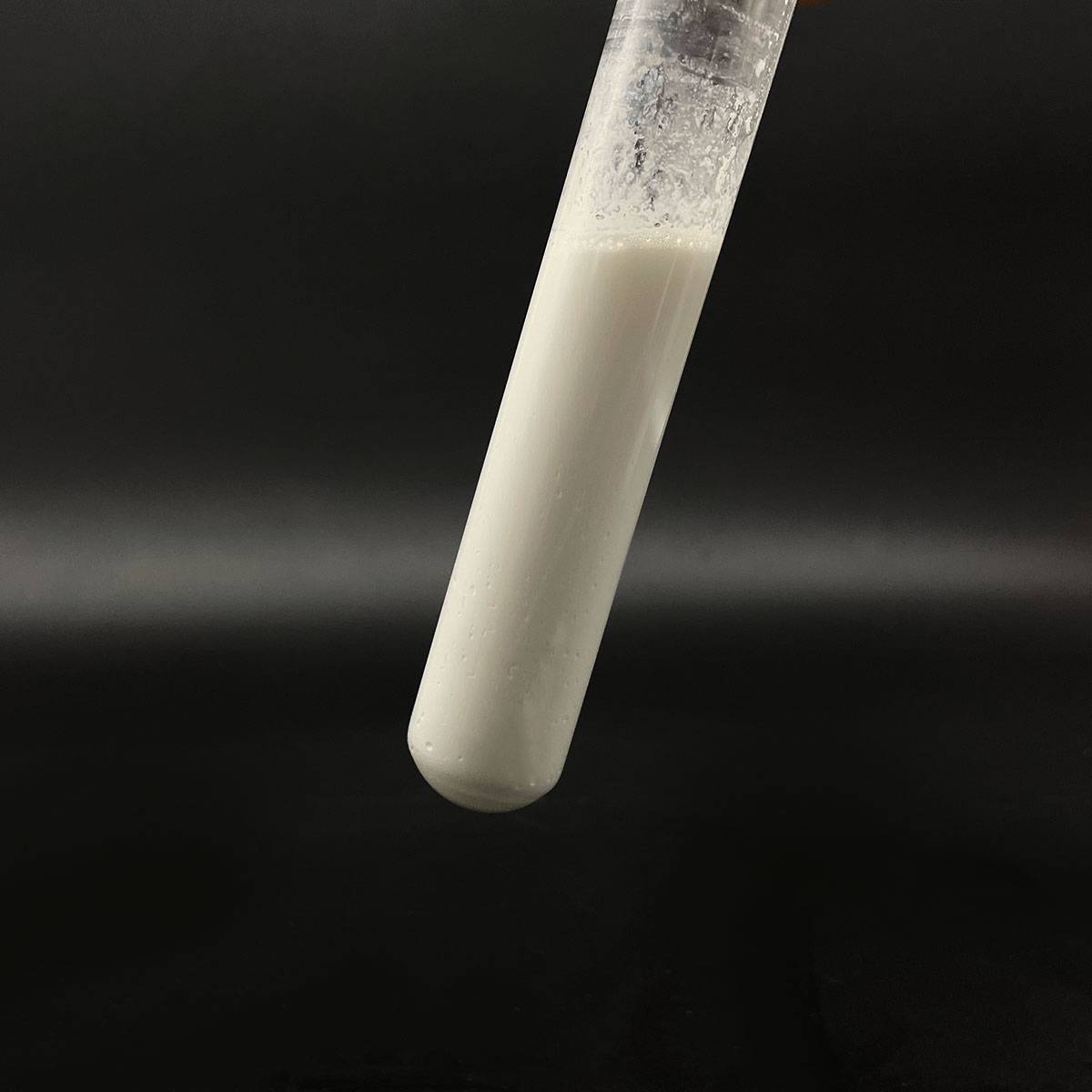

(Best 99.9% Min Tantalum Oxide best Ta2O5)

Parameters of Best 99.9% Min Tantalum Oxide best Ta2O5

Tantalum oxide (Ta2O5), also known as tantalum pentoxide, is a highly sought-after material due to its exceptional properties, making it indispensable in various industries, including electronics, aerospace, and chemical applications. When discussing the best 99.9% minimum tantalum oxide, we focus on parameters that ensure high purity, stability, and performance.

1. Purity: A purity level of 99.9% is crucial for Ta2O5, as impurities can significantly affect its electrical conductivity, thermal stability, and overall reliability. This ultra-high purity ensures that the material has minimal contamination, which is essential for critical applications like capacitors, sensors, and microelectronics.

2. Crystal Structure: The crystal structure of Ta2O5, typically hexagonal, plays a significant role in determining its properties. A well-ordered structure promotes better performance and stability. High-quality Ta2O5 should exhibit a consistent and pure hexagonal phase.

3. Particle Size and Distribution: For efficient use in thin films and powders, the particle size and distribution are critical. Smaller particles result in a larger surface area, enhancing reactivity and improving the material’s performance. A narrow particle size distribution ensures consistency across batches.

4. Surface Finish: A smooth and uniform surface finish is important for minimizing defects and ensuring compatibility with other materials during processing. This can be measured by techniques like scanning electron microscopy (SEM) or atomic force microscopy (AFM).

5. Thermal Stability: Ta2O5 must maintain its integrity under high temperatures, which is vital for applications such as heat sinks, furnace linings, and semiconductor processes. A high melting point and low thermal expansion coefficient contribute to this stability.

6. Chemical Resistance: Tantalum oxide is known for its excellent chemical resistance, but impurities can weaken this characteristic. The best Ta2O5 should maintain its integrity when exposed to harsh chemicals found in industrial environments.

7. Oxygen Content: Maintaining the stoichiometry of Ta2O5 is paramount for optimal performance. A precise oxygen content ensures that the material possesses the desired electronic properties and minimal reactivity.

8. Processing Parameters: The synthesis method, whether through precipitation, hydrolysis, or other routes, should yield a high-quality product. Optimal processing conditions, such as temperature, pressure, and reaction time, contribute to the formation of high-purity Ta2O5.

9. Contamination Control: During the production and handling process, strict cleanliness and contamination control measures must be in place to prevent the introduction of foreign elements into the final product.

10. Testing and Certification: The best Ta2O5 should undergo rigorous testing to confirm its properties, including elemental analysis, X-ray diffraction (XRD), and performance tests. Certifications from reputable organizations, such as ISO or IEC, ensure quality and consistency.

In summary, the best 99.9% minimum tantalum oxide is characterized by its high purity, well-defined crystal structure, controlled particle size and distribution, smooth surface finish, thermal stability, chemical resistance, precise oxygen content, optimized processing, stringent contamination control, and comprehensive testing and certification. These parameters work together to guarantee the material’s exceptional performance and reliability across a wide range of applications.

(Best 99.9% Min Tantalum Oxide best Ta2O5)

FAQs of Best 99.9% Min Tantalum Oxide best Ta2O5

Inquiry us