Overview of ASTM B708 high purity 99.95% tantalum sheet Tantal plates Ta blocks for corrosion-resistant industry

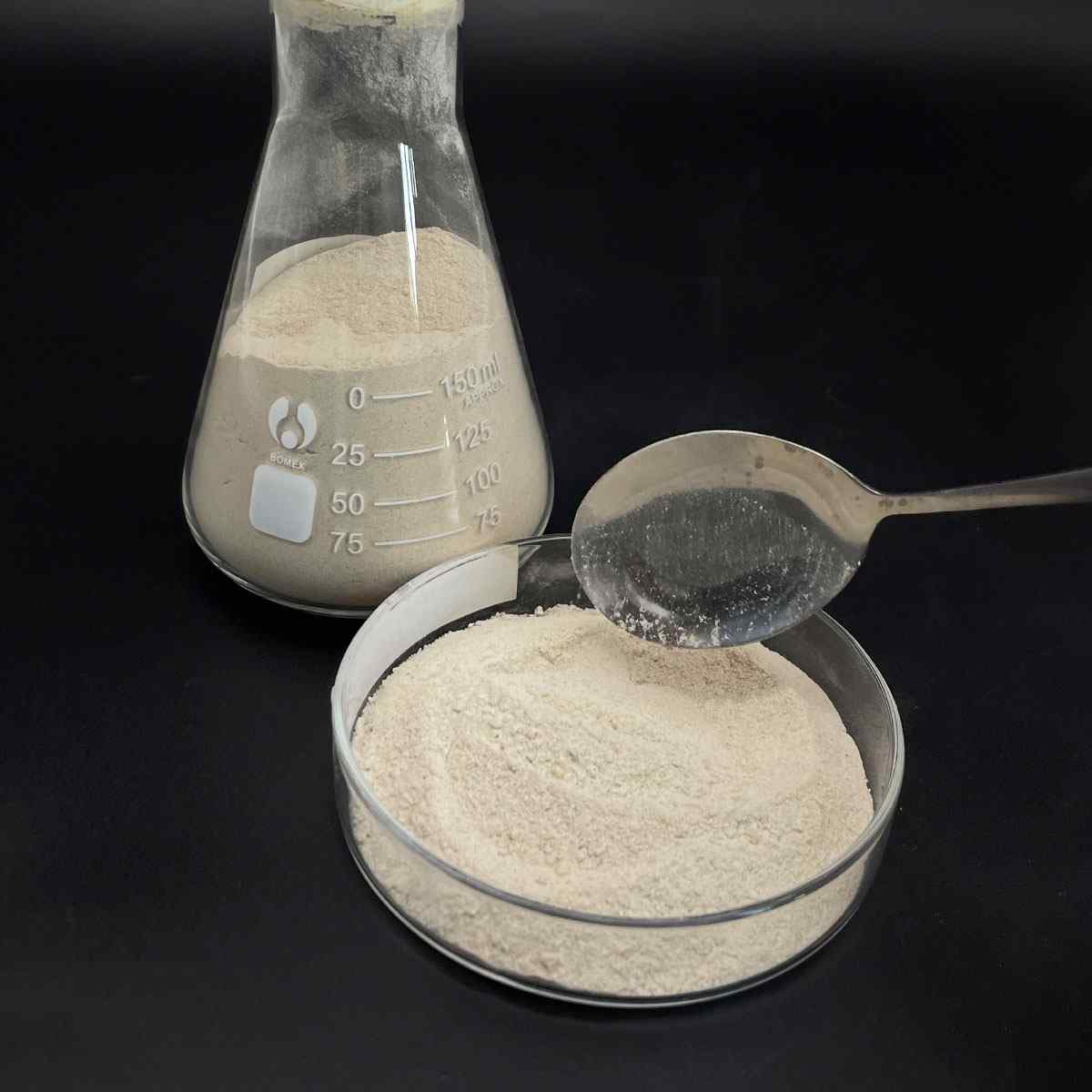

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of ASTM B708 high purity 99.95% tantalum sheet Tantal plates Ta blocks for corrosion-resistant industry

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(ASTM B708 high purity 99.95% tantalum sheet Tantal plates Ta blocks for corrosion-resistant industry)

Parameters of ASTM B708 high purity 99.95% tantalum sheet Tantal plates Ta blocks for corrosion-resistant industry

ASTM B708 high purity tantalum sheet, also known as Tantalum plates or Ta blocks, is a premium grade material designed specifically for applications in the corrosion-resistant industry. This particular grade boasts an exceptional purity level of 99.95%, ensuring unparalleled performance and durability.

Tantalum, with its chemical symbol Ta, is a rare, lustrous transition metal that exhibits remarkable resistance to corrosion, even in extreme environments. It ranks among the highest in the Corrosion Resistance Scale, making it ideal for use in industries where harsh conditions such as high temperatures, acidic or alkaline solutions, and mechanical stress are prevalent. These industries include aerospace, chemical processing, nuclear power, and semiconductor manufacturing.

The ASTM B708 specification outlines strict requirements for the quality and fabrication of tantalum sheets. It covers various dimensions, including thicknesses ranging from thin foils to thicker plates, ensuring consistency in product performance. The material is processed using advanced techniques to maintain its inherent properties, such as cold rolling, hot rolling, or vacuum melting, followed by precision cutting to produce the desired shapes and sizes.

The high purity of 99.95% ensures minimal contamination and impurities, which can significantly affect the material’s mechanical strength, conductivity, and resistance to wear. This purity level also contributes to improved thermal stability and resistance to radiation damage, making it suitable for applications like radiation shielding and high-temperature components.

In terms of mechanical properties, tantalum has excellent tensile strength, yield strength, and creep resistance, which means it can withstand long-term exposure to elevated temperatures without degrading. Its low coefficient of thermal expansion also minimizes stress-induced deformation, making it a reliable choice for components subjected to temperature fluctuations.

The corrosion resistance of tantalum is unparalleled, as it forms a natural oxide layer that protects the underlying metal from attack by most chemicals. This passive oxide film remains intact even under aggressive conditions, reducing maintenance requirements and extending the service life of components.

In summary, ASTM B708 high purity 99.95% tantalum sheets, plates, and blocks are a premium choice for the corrosion-resistant industry due to their exceptional purity, outstanding mechanical properties, and inherent resistance to harsh environments. Their widespread use in aerospace, chemical processing, nuclear, and semiconductor sectors highlights their critical role in ensuring reliability and longevity of equipment in these demanding applications.

(ASTM B708 high purity 99.95% tantalum sheet Tantal plates Ta blocks for corrosion-resistant industry)

FAQs of ASTM B708 high purity 99.95% tantalum sheet Tantal plates Ta blocks for corrosion-resistant industry

Inquiry us