Overview of 99.99% 99.999% Bismuth Telluride powder N type P type 325 mesh

Telluride and selenide compounds play a significant role in the field of semiconductors, particularly in the development of advanced electronic and optoelectronic devices. These materials belong to the chalcogenide family, characterized by their ability to form compounds with elements from groups IV-VI in the periodic table.

Tellurides: Compounds containing tellurium (Te) as the chalcogen. Examples include cadmium telluride (CdTe), mercury telluride (HgTe), and zinc telluride (ZnTe). These materials have found applications in solar cells, infrared detectors, and high-speed electronics due to their tunable bandgap, high electron mobility, and good thermal stability.

Selenides: Similar to tellurides, but with selenium (Se) replacing tellurium. Notable examples are cadmium selenide (CdSe), gallium selenide (GaSe), and zinc selenide (ZnSe). Selenide compounds are widely used in light-emitting diodes (LEDs), laser diodes, and solar cells due to their direct bandgap properties and efficient light absorption/emission capabilities.

Feature of 99.99% 99.999% Bismuth Telluride powder N type P type 325 mesh

Direct Bandgap: Many telluride and selenide semiconductors have direct bandgaps, which facilitate efficient light emission and absorption processes. This makes them suitable for optoelectronic applications such as LEDs and lasers.

Tunable Bandgap: The bandgap of these materials can be adjusted by alloying or altering the composition (e.g., CdSe to CdTe), enabling customization for specific device requirements across a wide spectrum of wavelengths.

High Electron Mobility: Materials like HgCdTe exhibit high electron mobility, which is crucial for high-speed electronic devices and low-noise detector applications.

Thermal Stability: Some tellurides and selenides, like ZnTe and ZnSe, demonstrate good thermal stability, making them suitable for high-temperature operation and processing.

Non-Toxic Alternatives: With increasing environmental concerns, there’s a push towards exploring less toxic alternatives to commonly used semiconductors. For instance, Cd-based tellurides and selenides are being replaced or combined with less toxic elements like Mg or Mn in some applications.

(99.99% 99.999% Bismuth Telluride powder N type P type 325 mesh)

Parameters of 99.99% 99.999% Bismuth Telluride powder N type P type 325 mesh

Bismuth Telluride (Bi2Te3), a promising material in the field of thermoelectricity, offers exceptional performance with high purity grades such as 99.99% and 99.999%. This compound is a key component in various applications, including waste heat recovery, power generation, and advanced electronic devices due to its unique properties.

The 99.99% pure Bi2Te3 powder is characterized by an extremely low impurity level, ensuring minimal degradation of its thermoelectric efficiency. This high purity grade is ideal for demanding applications where high reliability and long-term stability are paramount. The material’s crystal structure, primarily in the form of N-type or P-type semiconductors, allows for efficient conversion of temperature differences into electrical energy.

N-type Bi2Te3 refers to the dopant-induced electron-rich semiconductor, where certain elements, like antimony (Sb), have been intentionally added to increase the number of free electrons. This type is beneficial for cooling applications, as it generates a net negative Seebeck coefficient, converting heat to electricity effectively.

On the other hand, P-type Bi2Te3 is achieved by introducing hole-rich dopants, such as tellurium vacancies or copper (Cu), creating an imbalance of charge carriers. This type is more suitable for heating applications due to its positive Seebeck coefficient, enabling it to generate electricity from temperature gradients.

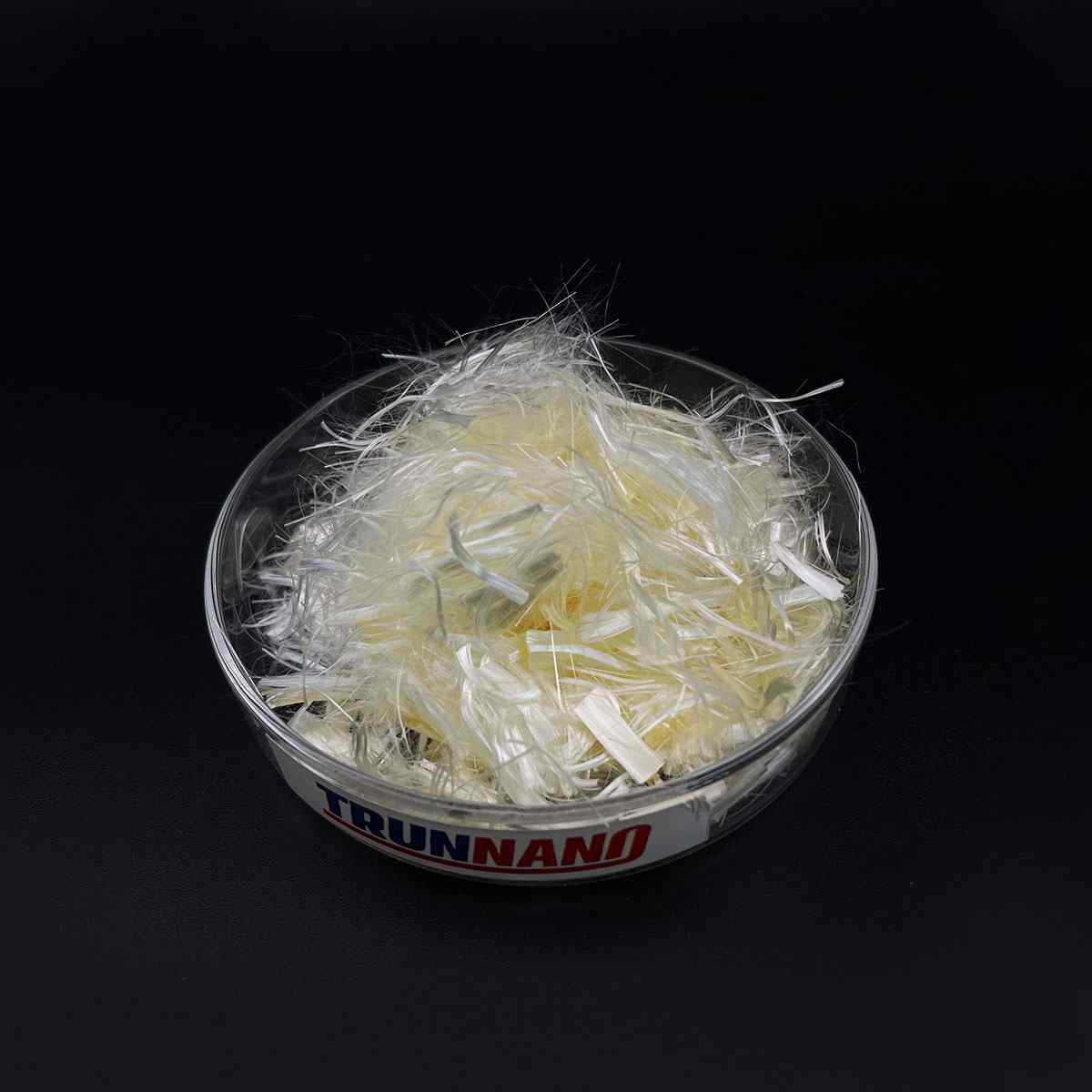

The 99.999% grade further enhances the material’s quality by reducing impurities to an incredibly low level. This ensures optimal performance, as even trace amounts of impurities can hinder the thermoelectric conversion process. The high purity Bi2Te3 powder is often ground into a fine 325 mesh size, which is crucial for achieving intimate contact between grains and facilitating heat transfer, thus maximizing the material’s thermoelectric figure of merit.

The 325 mesh parameter signifies that the powder particles are between 42 and 53 micrometers in diameter, providing a balance between surface area for efficient heat exchange and mechanical stability. This particle size is commonly used in thin film deposition, bulk materials, and composite structures for thermoelectric devices.

In conclusion, Bismuth Telluride powders with 99.99% and 99.999% purity, in both N-type and P-type configurations, offer exceptional thermoelectric performance. The choice of purity level and doping type depends on the desired application, while the 325 mesh size ensures optimal thermal conductivity and conversion efficiency. These high-quality powders play a pivotal role in the development of next-generation thermoelectric technologies, contributing to energy conservation and sustainable power generation.

(99.99% 99.999% Bismuth Telluride powder N type P type 325 mesh)

FAQ of Semiconductor Materials

Inquiry us