Overview of 99.9% Purity Molybdenum Sulfide Ceramic Material MoS2 Ceramic Targets For Thin Film Coating

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of 99.9% Purity Molybdenum Sulfide Ceramic Material MoS2 Ceramic Targets For Thin Film Coating

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(99.9% Purity Molybdenum Sulfide Ceramic Material MoS2 Ceramic Targets For Thin Film Coating)

Parameters of 99.9% Purity Molybdenum Sulfide Ceramic Material MoS2 Ceramic Targets For Thin Film Coating

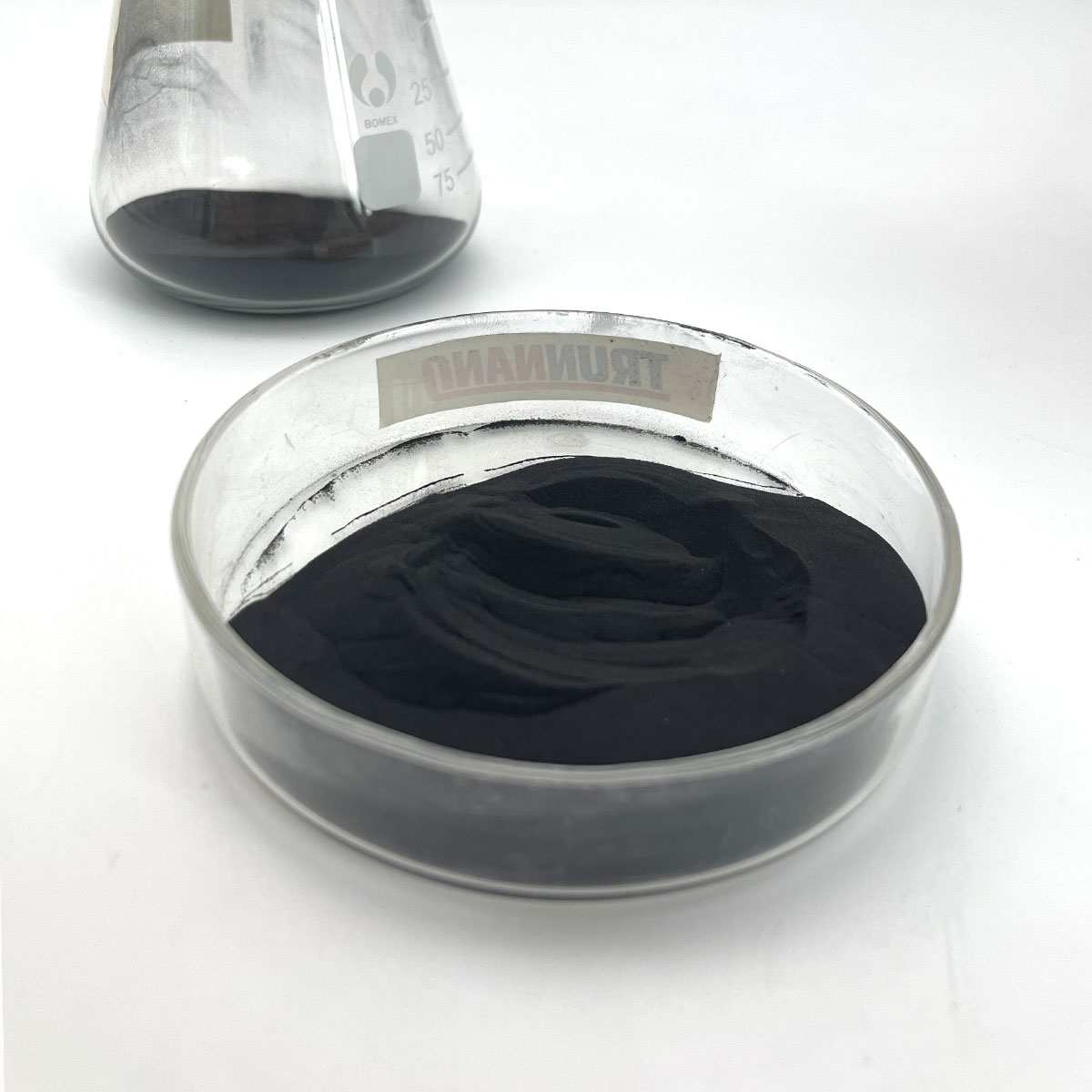

Molybdenum disulfide (MoS2), a high-purity ceramic material with a 99.9% purity, is a fascinating and versatile compound that has gained significant attention in various industries due to its exceptional properties. This two-dimensional material, often referred to as molybdenum sulfide nanosheets or MoS2 thin films, boasts remarkable characteristics such as high thermal stability, excellent electrical conductivity, and strong mechanical strength.

The process of manufacturing MoS2 ceramic targets for thin film coating involves meticulous purification of molybdenum metal and sulfur sources. The starting materials are carefully selected and processed to ensure the highest purity level, which is crucial for obtaining consistent and high-quality coatings. State-of-the-art techniques like chemical vapor deposition (CVD) or physical vapor deposition (PVD) are employed to deposit the MoS2 layers onto substrates.

During the thin film coating process, the MoS2 ceramic target is heated under controlled conditions, causing the release of sulfur and molybdenum atoms. These atoms then adhere to the substrate, forming a uniform and dense layer of MoS2. The purity of the material ensures minimal impurities, leading to improved film quality and performance.

The resulting MoS2 thin films exhibit unique optical properties, making them suitable for applications in optoelectronics, such as photodetectors and solar cells. They also have potential in lubrication, due to their low friction coefficients, and can be used in wear-resistant coatings for mechanical components. Additionally, MoS2’s catalytic properties make it an attractive choice for energy storage devices, particularly in lithium-ion batteries.

In terms of physical properties, MoS2 ceramic targets have a high melting point, which enables them to withstand elevated temperatures during the thin film deposition process. This thermal stability is critical for maintaining the integrity of the coating and ensuring long-term performance. Furthermore, the material’s inherent flexibility allows for the creation of flexible electronics, opening up possibilities in areas like wearable technology.

The manufacturing process for these ceramic targets is not only focused on achieving high purity but also on minimizing defects and grain boundaries, which can affect the final film’s performance. Advanced characterization techniques, such as X-ray diffraction (XRD) and scanning electron microscopy (SEM), are employed to verify the crystal structure and surface morphology of the MoS2 films.

In conclusion, 99.9% purity molybdenum sulfide ceramic material plays a pivotal role in the development of thin film coatings for a wide range of applications. Its unique properties, including high purity, thermal stability, and versatile functionality, make it a sought-after material in industries ranging from electronics to energy storage. As research continues to uncover more of MoS2’s potential, we can expect to see even more innovative uses for this remarkable ceramic compound.

(99.9% Purity Molybdenum Sulfide Ceramic Material MoS2 Ceramic Targets For Thin Film Coating)

FAQs of 99.9% Purity Molybdenum Sulfide Ceramic Material MoS2 Ceramic Targets For Thin Film Coating

Inquiry us