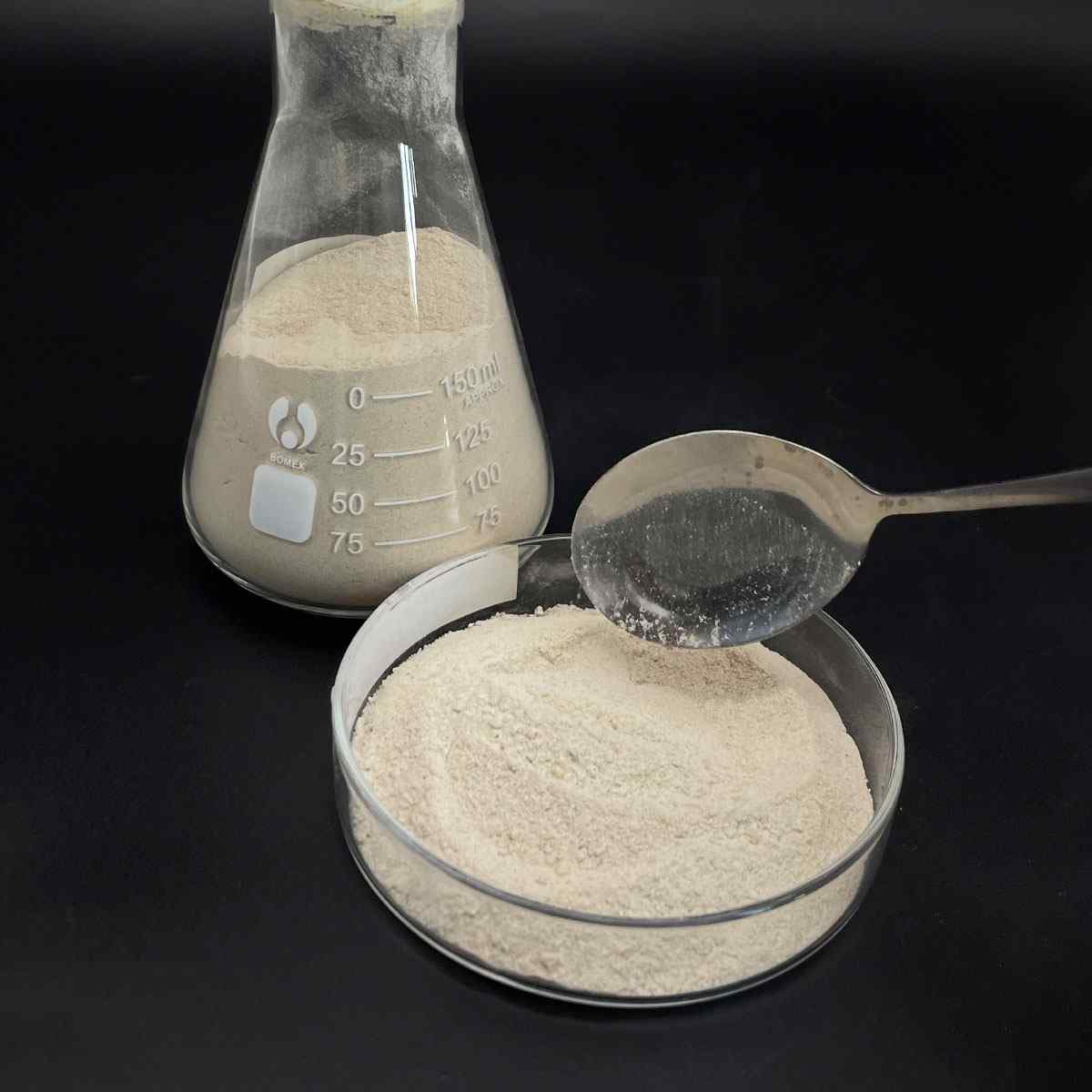

Overview of -325 mesh Nb metals basis Niobium Metal Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of -325 mesh Nb metals basis Niobium Metal Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(-325 mesh Nb metals basis Niobium Metal Powder)

Parameters of -325 mesh Nb metals basis Niobium Metal Powder

Title: An Insight into Nb (Niobium) Metal Powder with -325 Mesh: Properties and Applications

Niobium, often abbreviated as Nb, is a chemical element with the atomic number 41, belonging to the transition metal group in the periodic table. It is a lightweight, strong, and ductile metal that exhibits unique properties, making it an essential material in various industries, particularly in advanced technologies such as superconductors, aerospace, and nuclear applications.

The -325 mesh size refers to the particle size distribution of the Nb metal powder. In this context, “mesh” is a standard measurement system used for powders, where a finer mesh number indicates smaller particles. A -325 mesh typically corresponds to particles ranging from approximately 45 microns to 75 microns in diameter. This particle size is crucial as it affects the powder’s flowability, reactivity, and packing density, which in turn influences its processing characteristics and final product performance.

Niobium metal powder, with its -325 mesh, offers several advantages. Firstly, the relatively large particle size ensures better handling and reduced caking, making it easier to process during melting or sintering. The larger particles have lower surface-to-volume ratios, which can reduce the risk of unwanted reactions and improve overall efficiency in forming and joining processes.

In terms of mechanical properties, -325 mesh Nb metal powder exhibits excellent strength and ductility. At elevated temperatures, niobium maintains its strength, making it suitable for high-temperature applications like jet engines and nuclear reactors. The combination of strength and formability allows for the fabrication of intricate components with precise geometries.

Superconductivity is another key attribute of niobium, particularly when combined with other elements like tin (NbTi) or vanadium (Nb3Sn). The -325 mesh powder is commonly used in the production of high-temperature superconducting wires and magnets, where the fine grain structure contributes to the efficient transfer of electrical current without resistance.

In the aerospace industry, niobium finds application in lightweight structures due to its low density and high strength. The -325 mesh powder enables the manufacturing of thin-walled components for gas turbines and aircraft parts, contributing to fuel efficiency and reduced weight.

For nuclear power generation, niobium plays a vital role in the construction of steam generator tubes and other heat exchanger components. The -325 mesh powder ensures a uniform distribution of the metal, leading to improved heat transfer and durability.

Moreover, niobium metal powder is also employed in the production of magnetic devices, where its high magnetic permeability and low coercivity make it ideal for electromagnetic shielding and microwave components.

In summary, the -325 mesh Nb metal powder, with its distinct particle size, offers a balance between ease of processing and superior mechanical properties. Its versatile nature makes it indispensable in a wide range of applications, from cutting-edge technology like superconductors to traditional industries like aerospace and nuclear power. As research and innovation continue to advance, the importance of niobium metal powder, especially in the -325 mesh format, will likely grow in the coming years.

(-325 mesh Nb metals basis Niobium Metal Powder)

FAQs of -325 mesh Nb metals basis Niobium Metal Powder

Inquiry us