Overview of 3 layers rotary molybdenum powder automatic vibrating screen /sieve

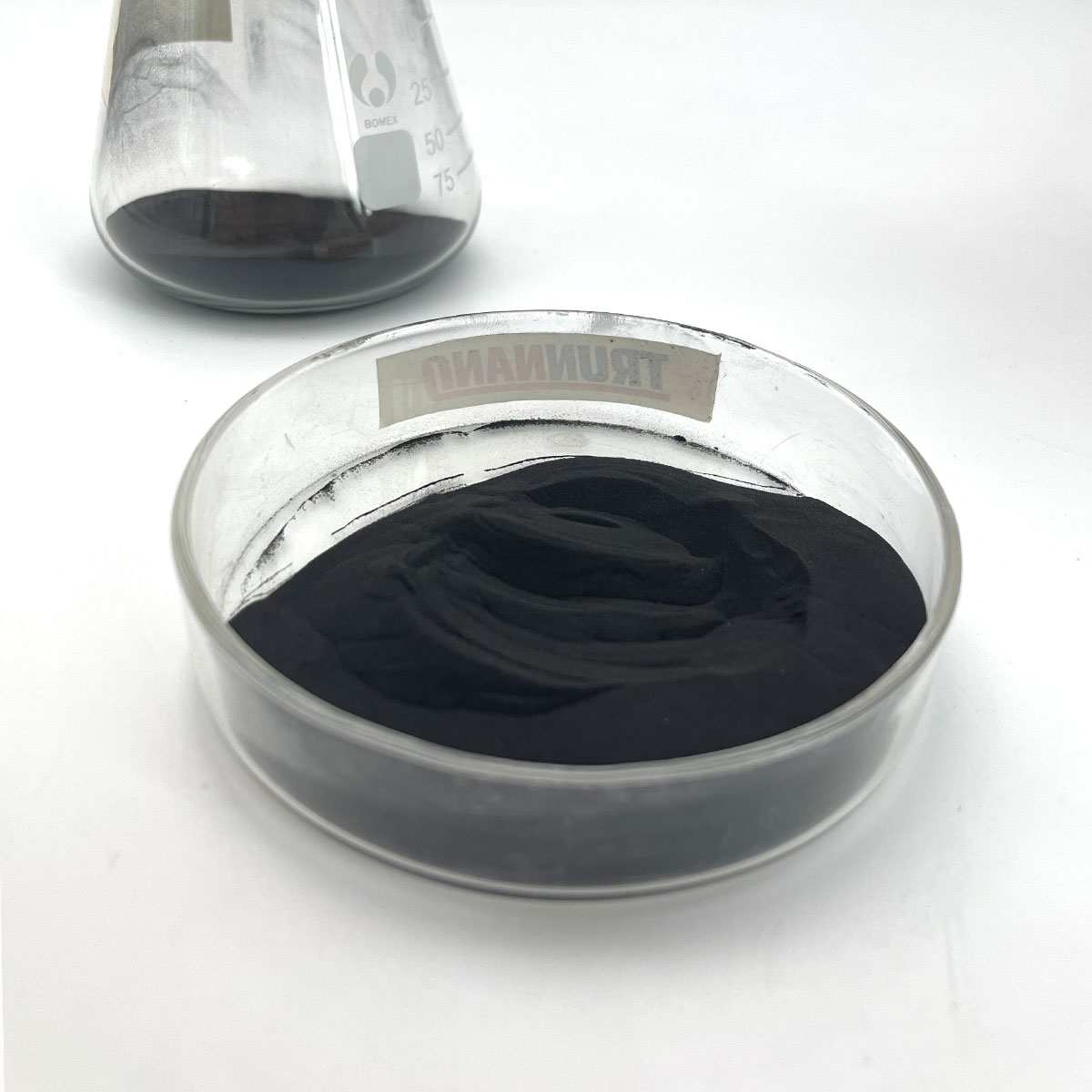

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of 3 layers rotary molybdenum powder automatic vibrating screen /sieve

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(3 layers rotary molybdenum powder automatic vibrating screen /sieve)

Parameters of 3 layers rotary molybdenum powder automatic vibrating screen /sieve

The Rotary Molybdenum Powder Automatic Vibrating Screen/Sieve is a highly advanced and efficient piece of equipment designed specifically for the separation and grading of molybdenum powders in a three-layer configuration. This innovative machine integrates precision engineering with user-friendly technology to streamline the process, enhance productivity, and ensure consistent product quality.

Key Parameters:

1. Screen Size: The screen dimensions are tailored to accommodate the particle size range of molybdenum powders, providing ample surface area for effective separation. The precise dimensions allow for optimized throughput and minimal material loss.

2. (Layers): The three-layer design ensures multiple stages of screening, which improves the separation efficiency by capturing particles of varying sizes in different compartments. This allows for a more refined final product.

3. Material Type: Made from high-quality materials like stainless steel or durable alloys, the vibrating screen is corrosion-resistant and durable, ensuring long-term performance under harsh industrial conditions.

4. Vibrating Motor: The motor drives the screen’s vibratory motion, which is precisely controlled for optimal particle movement across the screen surface. This ensures efficient sieving and minimizes clogging.

5. Frequency and Amplitude: Adjustable frequency and amplitude settings enable operators to fine-tune the separation process according to the specific requirements of the molybdenum powder being processed.

6. Automation: The machine features an automated control system that monitors and adjusts the operation based on preset parameters or real-time data. This eliminates manual intervention, reduces errors, and increases productivity.

7. Feed Capacity: Capable of handling a wide range of feed rates, the screen can process large volumes of molybdenum powder efficiently, without compromising on screening accuracy.

8. Efficiency: The three-tiered design allows for a higher degree of separation, resulting in a cleaner and more uniform product distribution. This translates into improved overall plant efficiency and cost savings.

9. Maintenance: Regular inspection and maintenance intervals are built into the design, minimizing downtime and facilitating quick repairs when necessary.

10. Environmental Considerations: The machine incorporates dust suppression measures to minimize airborne contamination and maintain a clean working environment.

In conclusion, the Rotary Molybdenum Powder Automatic Vibrating Screen/Sieve is a sophisticated, user-friendly, and environmentally friendly solution for refining molybdenum powders. Its multi-layer design, advanced automation, and robust construction make it an indispensable tool for industries that rely on precise particle sizing in their processes. By optimizing the separation process, this equipment enhances productivity, quality, and sustainability.

(3 layers rotary molybdenum powder automatic vibrating screen /sieve)

FAQs of 3 layers rotary molybdenum powder automatic vibrating screen /sieve

Inquiry us